Scrap submunition bullet decomposition machine

A dismantling machine and cluster bomb technology, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of bullet decomposition requirements that cannot be integrated into scrap cluster bullets, low efficiency of personnel decomposition, and low level of mechanization, so as to reduce auxiliary operation time, Compact structure, the effect of improving the degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

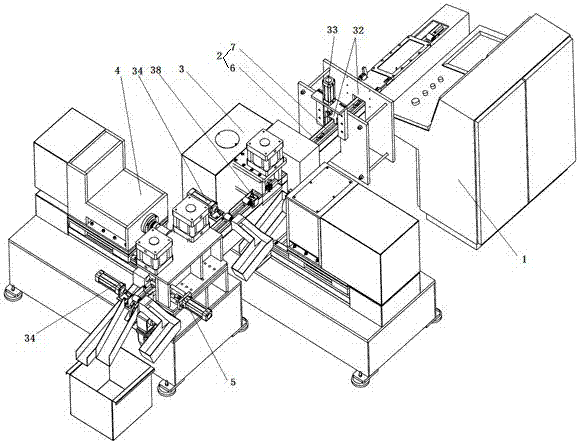

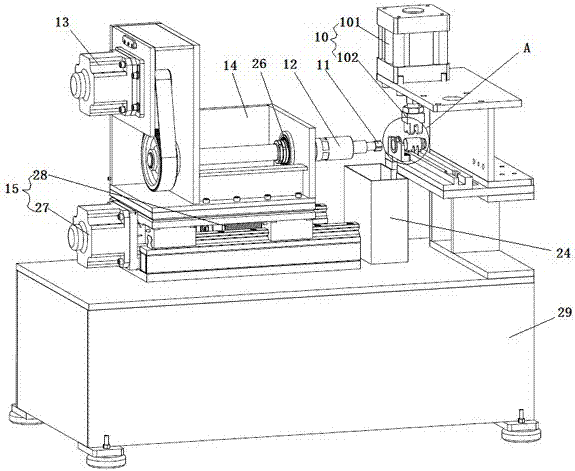

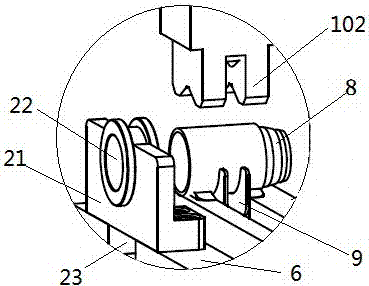

[0026] Such as figure 1 A kind of disintegrating machine for discarded submunition bullets shown includes a control cabinet 1 and a transmission device 2 connected thereto, a fuze unscrewing device 3, a screw pressing disassembly device 4, a forming charge column and a drug type cover extruding device 5, said The transmission device 2 includes a workbench 6 and a conveying chain 7 arranged on the workbench 6, the conveying chain 7 is driven by a motor 48, and the conveying chain 7 is provided with draw-in slots 9 for limiting bullets 8 at intervals; 1. Screw-pressing decomposing device 4 and forming drug column and drug-type cover extruding device 5 are sequentially arranged on the workbench 6 on both sides of the conveying chain 7 in the conveying direction.

[0027] Place the bullet 8 in the card slot 9 on the conveying chain 7 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com