Pipeline support equipment and pipeline installation and adjustment method using the equipment

A pipeline installation and pipeline technology, applied in the direction of pipeline supports, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of isolation device damage, difficult operation of pipeline centering adjustment, vibration, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

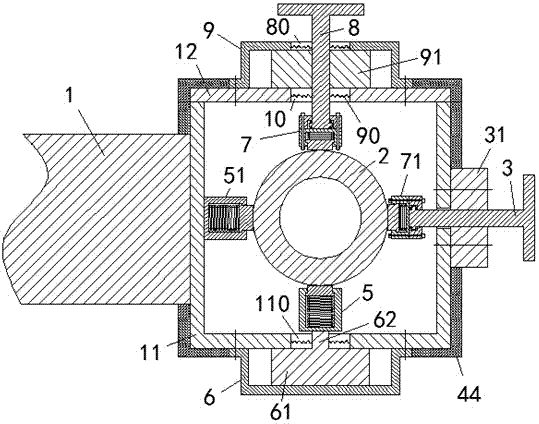

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] A pipeline supporting device according to an embodiment includes a fixed base frame 1 , a box body 11 fixed with the fixed base frame 1 , and a box body cover 12 detachably fixed with the box body 11 . The box body The cover 12 covers the upper opening of the box body 11 to allow the pipe 2 to pass through the upper opening when dismantling. The upper slider 91 is slidably clamped between the upper slider clamping cover 9 and the box cover 12 , and the upper slider 91 is provided with a screw hole for threading with the longitudinal axis operating screw 8 Matching, the outer part of the longitudinal axis operating screw 8 passes through the upper slider to clamp the cover 9 and has a first adjustment margin 80 between the two adjacent sides of the upper slider to clamp the cover 9 , the inner part of the longitudinal axis operating screw 8 passes through the box cover 12 and has a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com