Multi-way valve

A multi-way valve and valve housing technology, applied in the field of multi-way valve, can solve the problems of increasing manufacturing cost, difficulty, controlling piston deformation, etc., and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

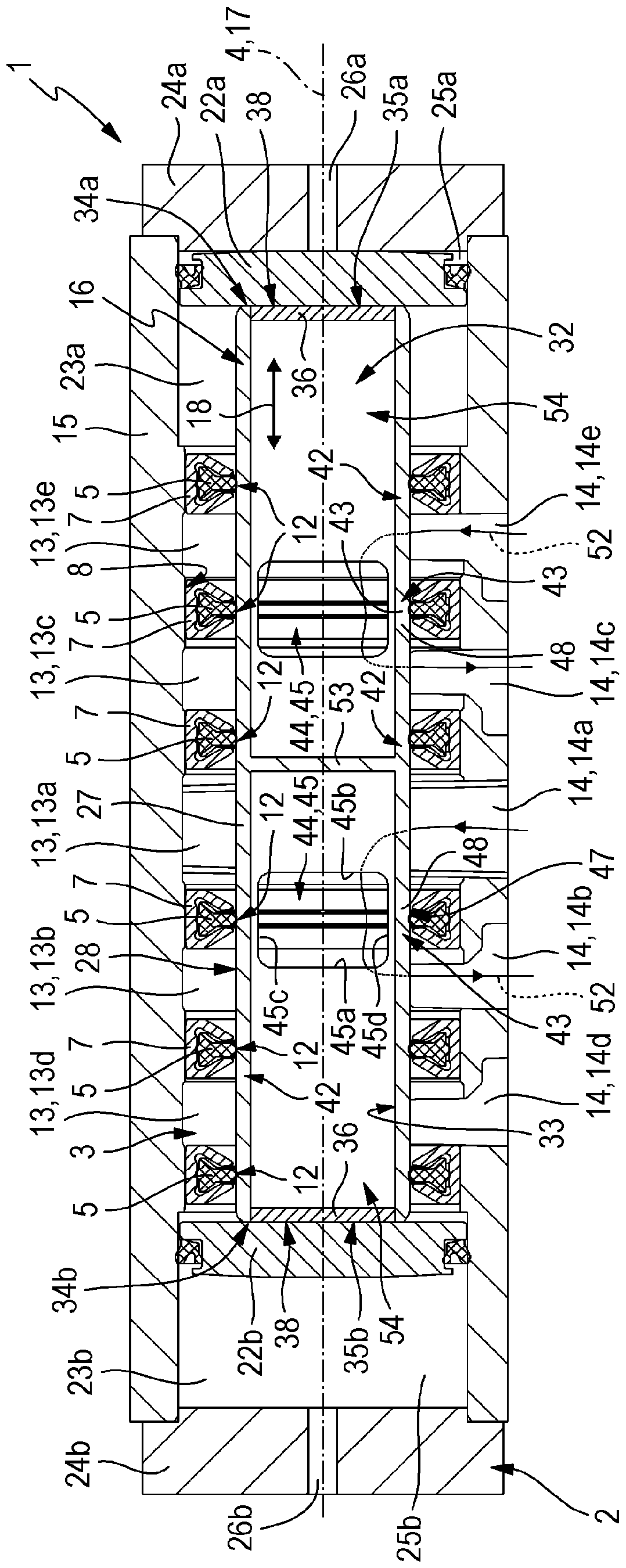

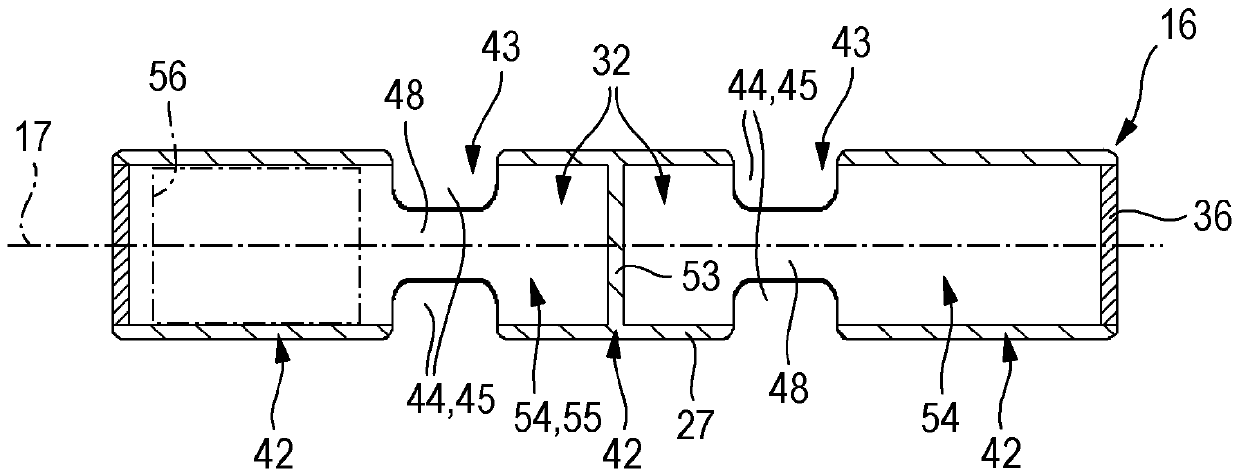

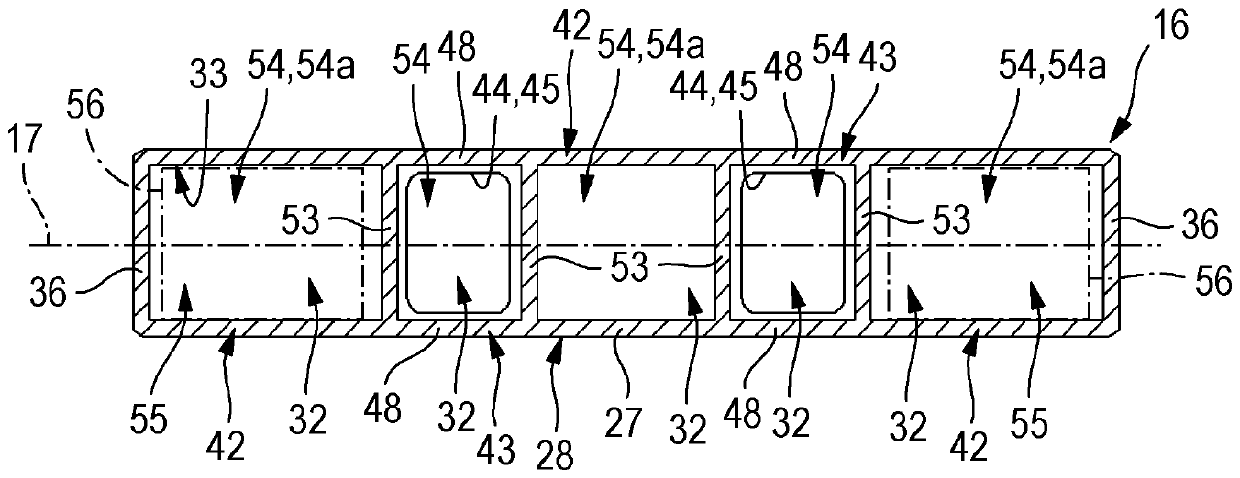

[0034] The multi-way valve 1 illustrated in the drawing in a preferred embodiment has a valve housing 2 in which an elongated housing recess 3 is formed and which has a longitudinal axis 4 .

[0035] A plurality of annular sealing elements 5 are arranged coaxially in the housing groove 3 and axially spaced apart from one another. The sealing element 5 is fixed in a stationary manner relative to the valve housing 2 in the axial direction of the longitudinal axis 4 . Preferably, each sealing element 5 is part of an annular sealing unit 6 which is fixed axially immovably coaxially with respect to the longitudinal axis 4 in the housing groove 3 . Each sealing unit 6 advantageously comprises an annular, U-shaped seal housing 7 in cross-section, the U-shaped hole of which points radially inwards in the direction of the longitudinal axis 4 and in which the respective annular sealing element is held. One of 5.

[0036] The sealing housing 7 is preferably pressed into the housing gro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap