Locking cap of standardized self-locking and screw thread-locking liquid distribution pump

A screw lock and dispensing pump technology, which is applied in the field of locking caps, can solve the problems of increasing mold opening costs, increasing assembly costs, and inability to realize different functions, and achieves the effects of convenient use, liquid leakage prevention, and convenient and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

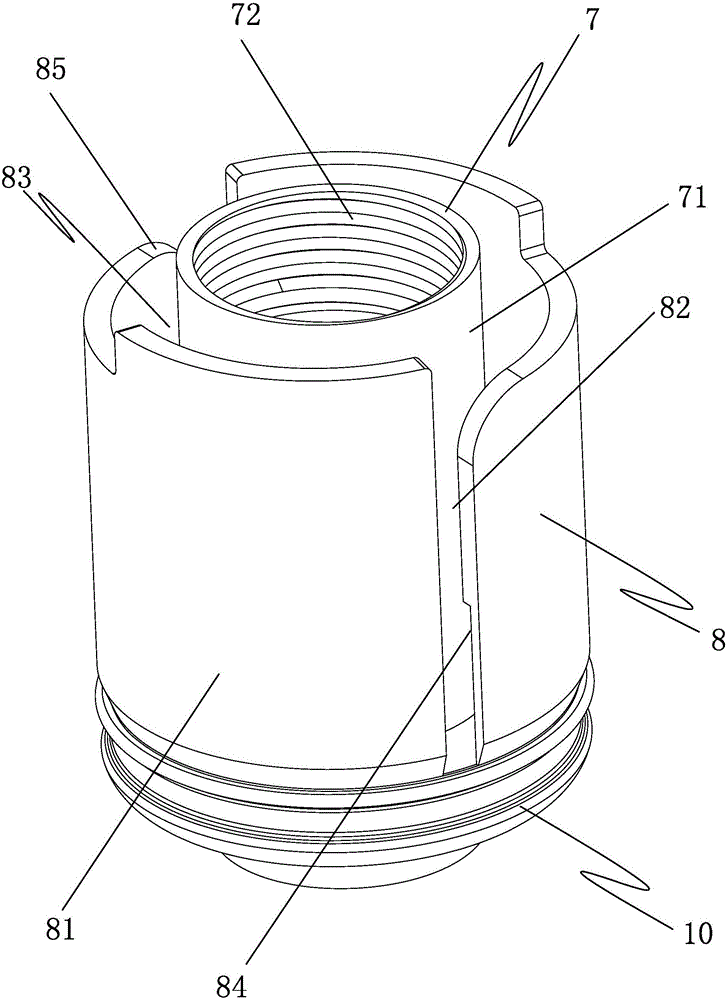

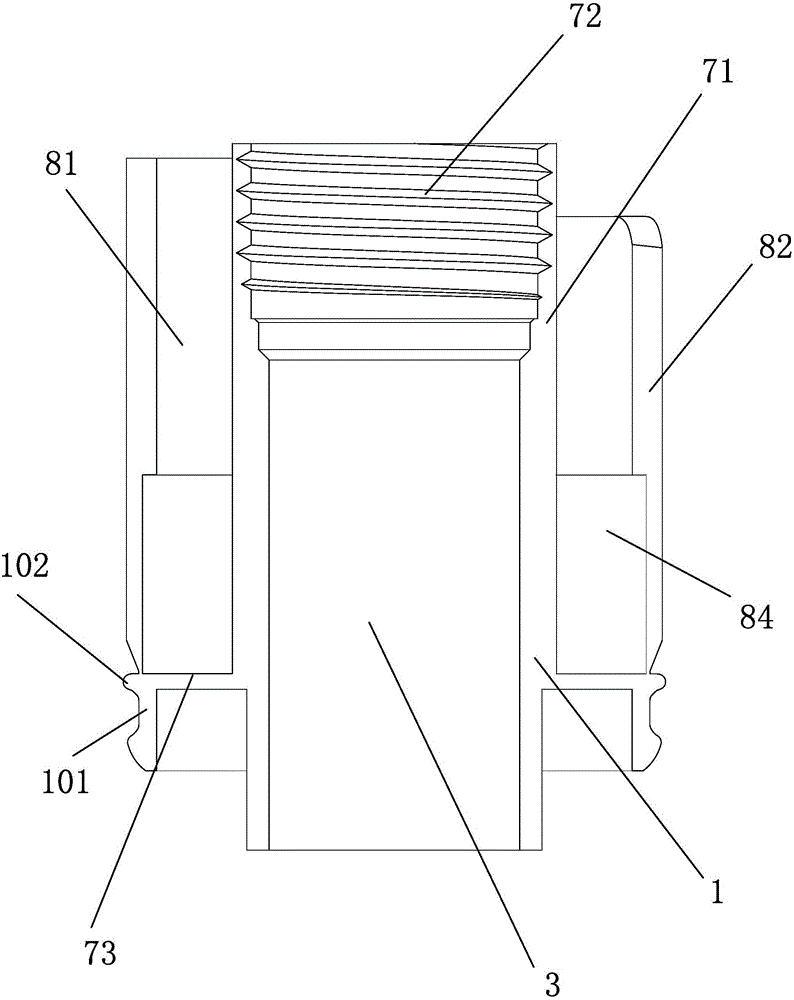

[0032] like Figures 1 to 4 The locking cover of the standardized self-locking and screw-locking liquid distribution pump shown includes a locking cover cover body 1, and a longitudinal through hole 3 capable of accommodating the pump rod 2 is provided in the locking cover cover body 1. , the upper end of the locking cover body 1 is provided with a screw locking connection part 7 which can cooperate with the external connecting thread 6 arranged on the outer wall of the pump rod connecting part 5 of the elbow pressing head 4 to realize screw locking , a self-locking connection part 8 is provided on the locking cover body 1 outside the screw locking connection part 7, and a snap connection for connecting with the pump chamber 9 is provided on the outer wall of the locking cover cover 1 Section 10. In the present invention, a screw locking conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com