Automatic marking device in sheath inspection

A sheathing and automatic technology, applied in typewriters, printing, etc., can solve the problems of easily misaligned labels and unclear information instructions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

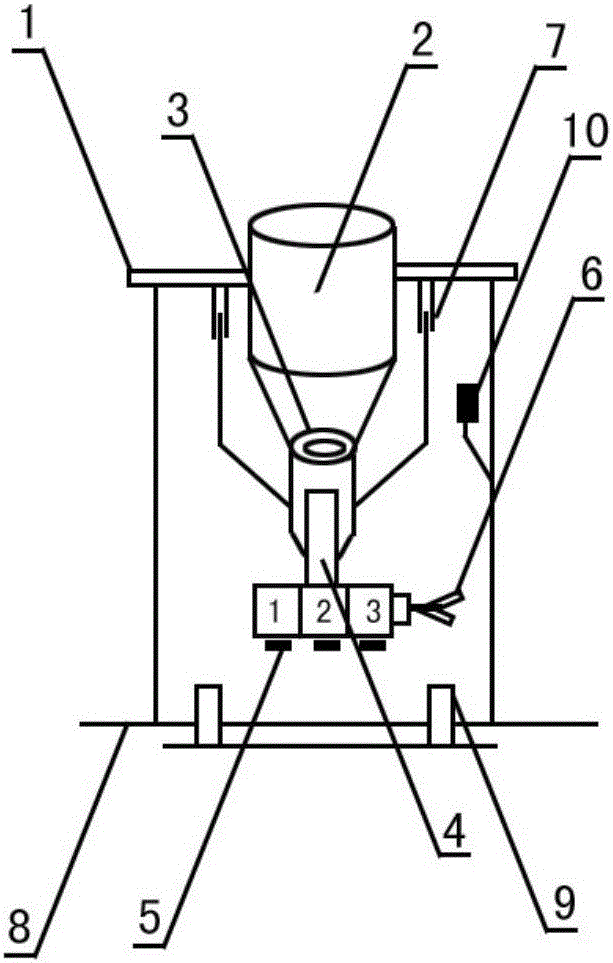

[0012] Embodiment: as shown in the accompanying drawing. The automatic marking device in the sheath inspection includes a frame (1), and a standard liquid storage device (2), a volume control ball (3), an infusion tube (4) and a marking structure are arranged on the upper part of the frame (1) The connection includes a digital base block (5), a control device (6), a lifting assembly (7) of equal structure is arranged on both sides of the standard liquid storage device (2), a sliding base (8) and a fixing device (9) are arranged at the bottom, It is connected with an external power supply during operation, and the wire harness sheath after inspection is positioned on the fixing device (9) according to the size specification and the required marking surface for automatic marking operation.

[0013] For the automatic marking device in the sheath inspection, the inner side of the fixing device (9) is provided with a sensing module connected to the prompting device (10), and a corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com