Three-hole flange automatic pin retreating mechanism

A flange and automatic technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient tooling change for workers, increase the overall weight of tooling, cumbersome operation, etc., to reduce the weight of tooling, Space-saving and reduced-complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

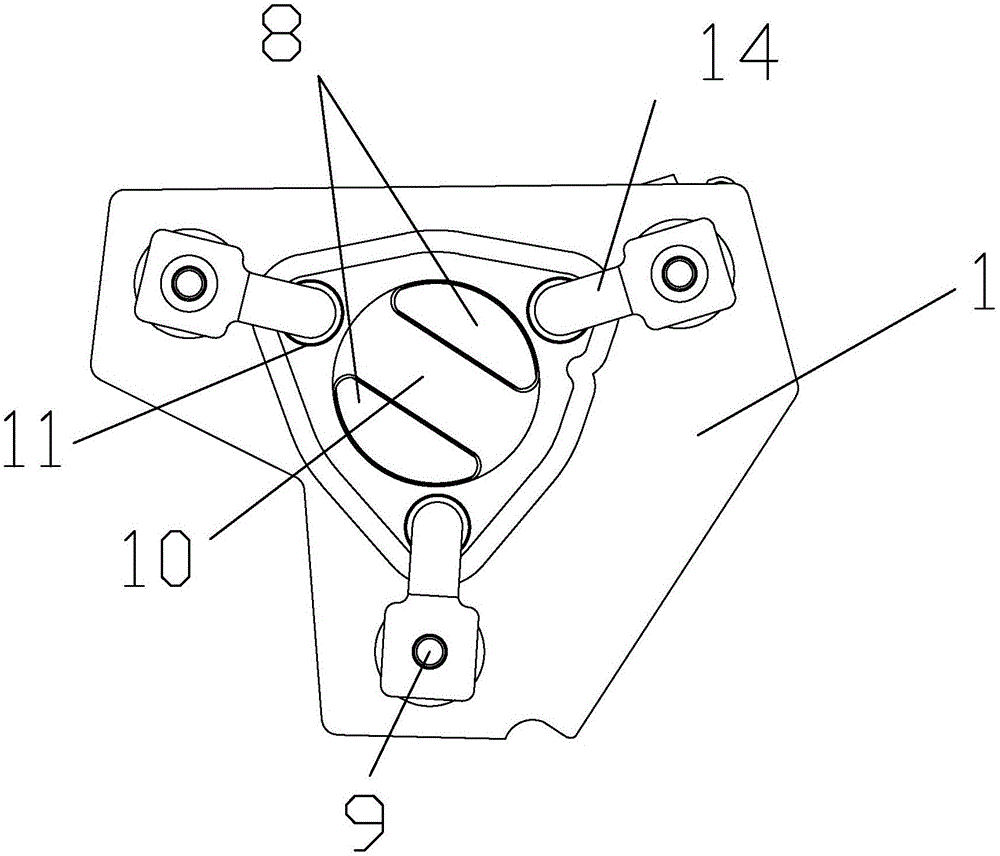

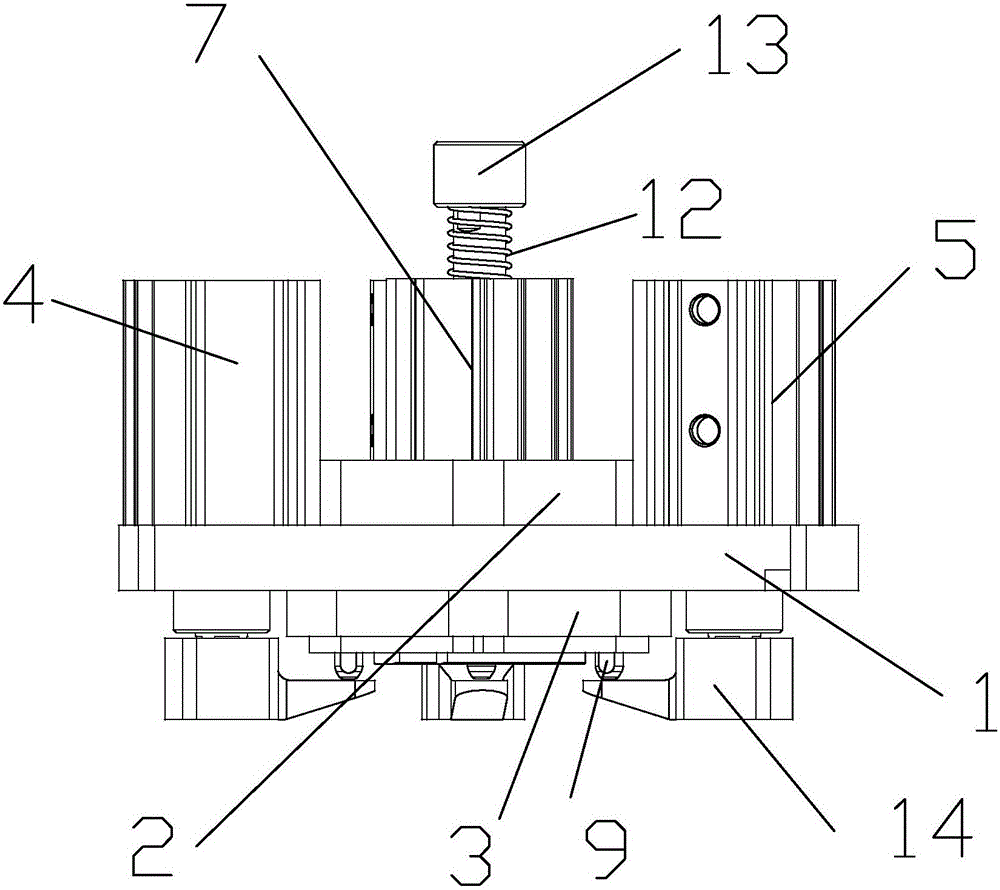

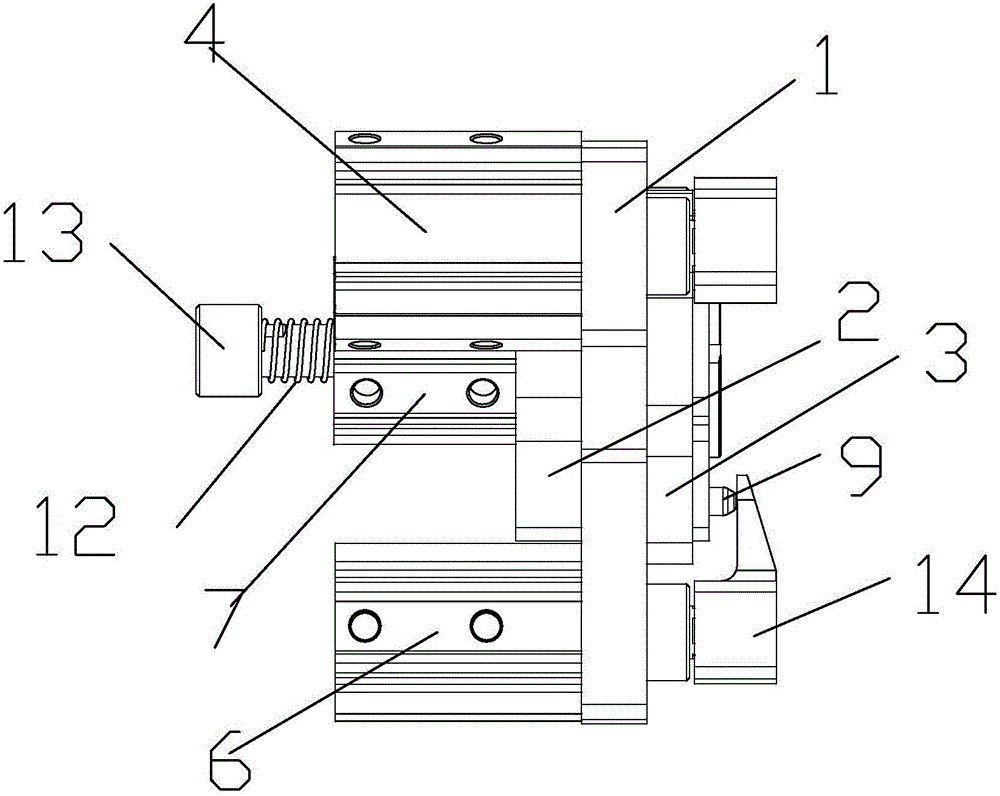

[0018] Such as Figures 1 to 3 As shown, a three-hole flange automatic cancellation mechanism includes a main positioning plate, a flange backing plate is fixed on one side of the main positioning plate, and a first cylinder, a second cylinder and a third cylinder are fixed on the other side. The cylinders are distributed in an equilateral triangle; the center of the triangle surrounded by the first cylinder, the second cylinder and the third cylinder is provided with a fourth cylinder whose end is fixedly connected to a first positioning plate, and three cylinders are installed on the first positioning plate. A positioning core and two semicircular positioning blocks; the ends of the first cylinder, the second cylinder and the third cylinder pass through the main positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com