An anti-falling lightning rod

A lightning rod and anti-dropping technology, which is applied in the field of lightning rods, can solve problems such as no strengthening measures for lightning rods, shaking of lightning rods, broken and dropped lightning rods, etc., and achieve the effects of avoiding lateral vibration, reducing shaking amplitude, and preventing breakage and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

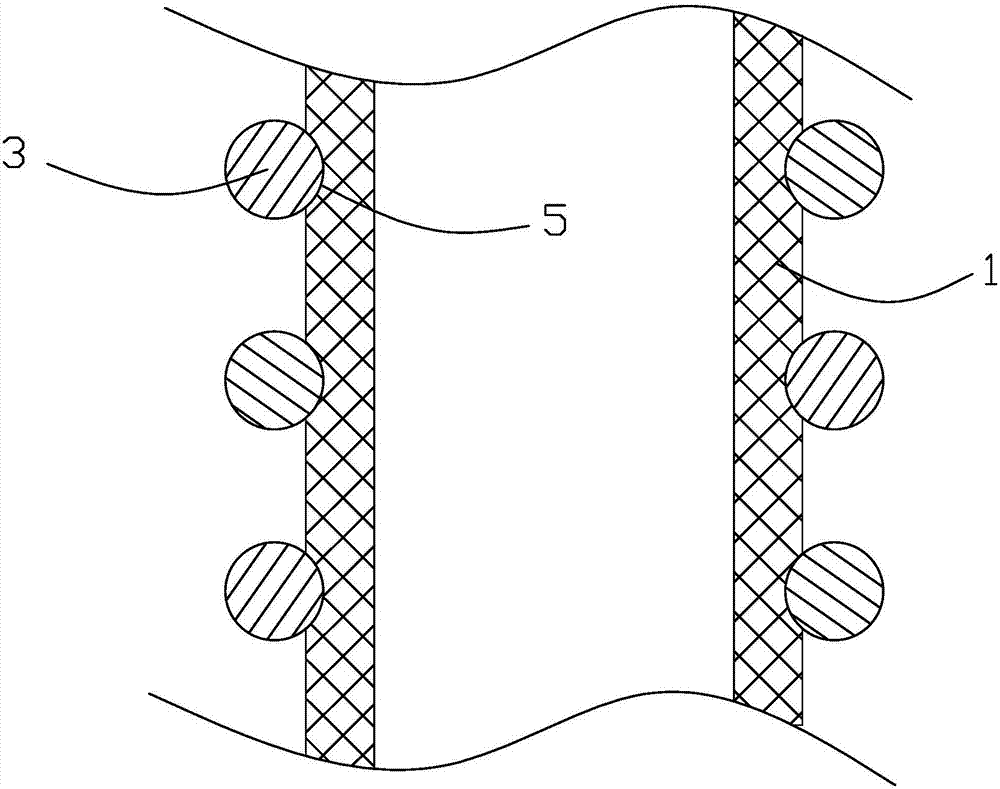

[0019] This embodiment is an anti-dropping lightning rod, such as figure 1 As shown, the lightning rod 1 is installed on the top of the tower body 2, and a winding wire 3 is arranged on the outer wall of the lightning rod. The winding wire adopts a whole metal wire, such as image 3 As shown, the upper part of the lightning rod is provided with a perforation 6, the winding wire passes through the perforation, the middle of the winding wire is fixed at the perforation, and the two ends of the winding wire are helically wound on the outer wall of the lightning rod in the opposite direction of rotation. The winding method can also adopt the double spiral winding on the outer wall of the lightning rod without cross winding in the same direction of rotation.

[0020] In order to further prevent vortex shedding, such as figure 2 As shown, a corresponding cross double spiral groove 5 is provided on the outer surface of the lightning rod, and the winding wire is wound in close contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com