Production process and products of EPDM microporous backing plate

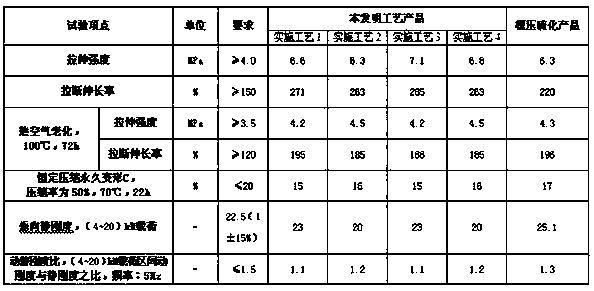

A kind of EPDM rubber and production process technology, applied in the field of microporous rubber production, can solve the problems of poor product structure applicability, low production efficiency, high labor intensity, etc., achieve fast vulcanization speed, save investment, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below.

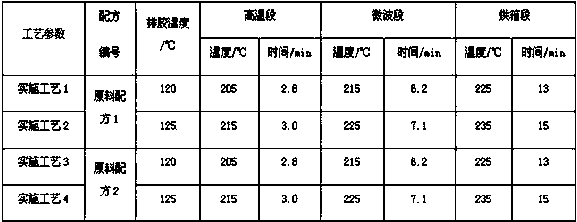

[0037] The production technology of EPDM microporous backing plate is characterized in that comprising the following steps:

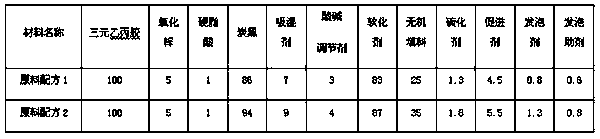

[0038] S1: Put EPDM rubber into the kneader and knead for 30-40 seconds, then put zinc oxide, stearic acid, carbon black, hygroscopic agent, acid-base regulator, softener and inorganic filler into the kneader Knead for 5 to 10 minutes, and the temperature of glue discharge is 115 to 130°C to prepare the masterbatch;

[0039] S2: Put the masterbatch prepared in S1 into the mill, add vulcanizing agent, accelerator, foaming agent, and foaming aid, and after mixing evenly, open the cooling water circulation system of the mill so that during the milling process, The temperature of the mixture in the open mill does not exceed 45°C, adjust the roller distance to 0.8-1.3 mm for thin pass, make a triangular bag 3-4 times, and then adjust the roller distance to 5-6 mm for sheeti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com