Lead screw and omnidirectional mechanism for adjusting eccentricity of screw

A technology of universal mechanism and adjusting screw, which is applied in the direction of mechanical equipment, belts/chains/gears, transmission devices, etc., which can solve the problem of uneven force on nuts and screw rods, affecting the life of the screw rod, equipment use, and aggravating the screw rod and nut. Friction and other problems, to achieve stable and reliable structure, improve service life, reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

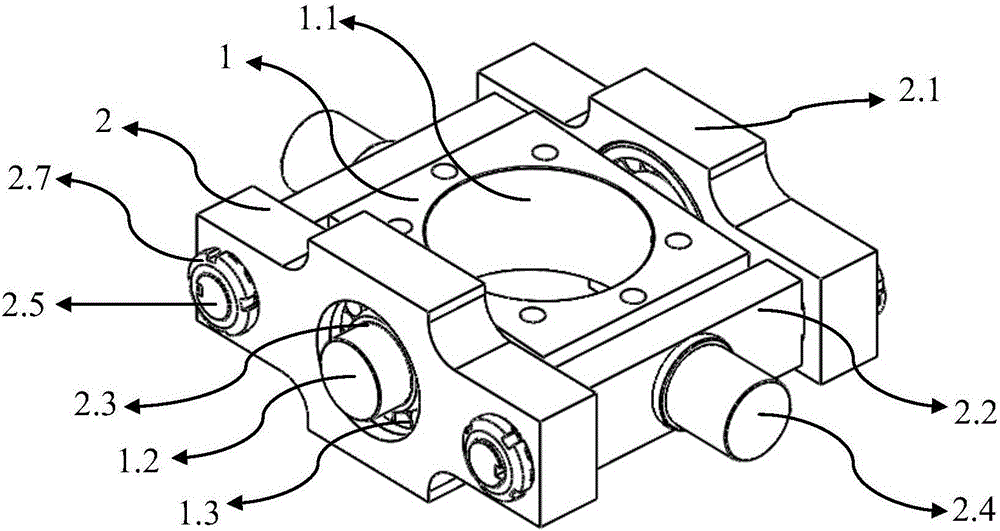

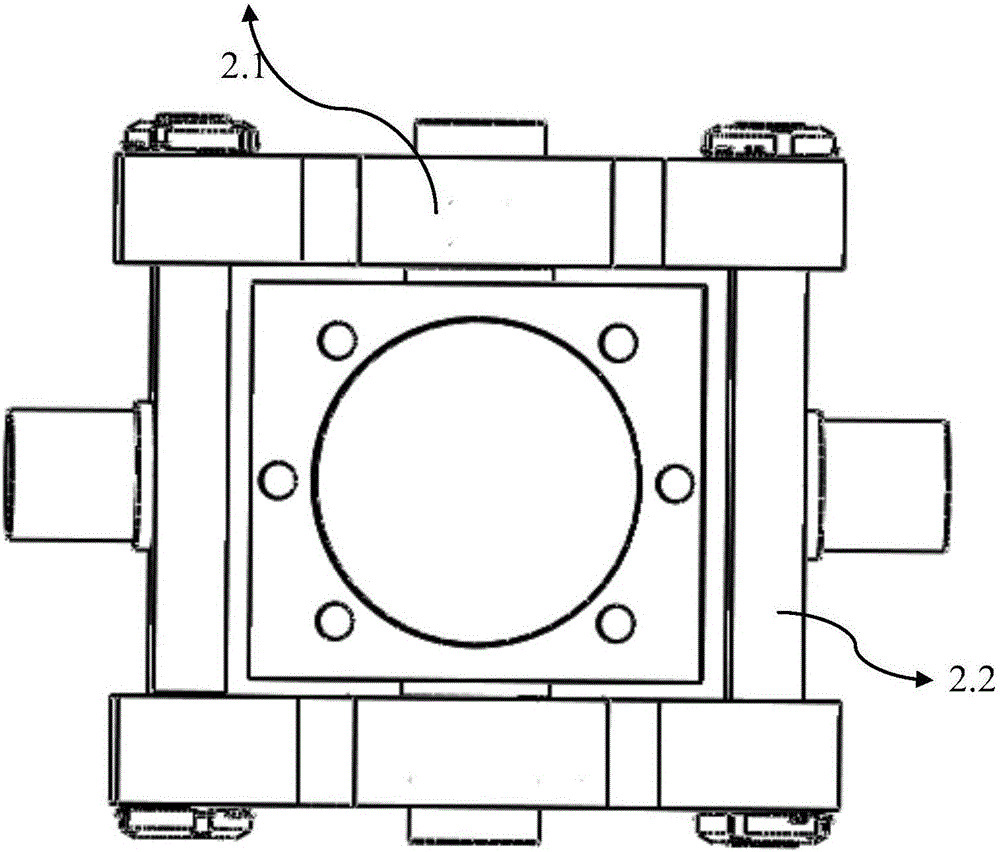

[0024] Such as Figure 1-5 As shown, a universal mechanism 10 for adjusting the eccentricity of the screw includes an inner plate 1 and an outer plate 2, the inner plate is provided with a central through hole 1.1 formed therein, and a pair of inner bushings 1.2 are provided outside the inner plate, The inner shaft sleeve is parallel to the plane of the inner plate, and the inner shaft sleeve 1.2 is covered with a ball bearing 1.3, which is connected with the inner shaft sleeve cavity 2.3 through the ball bearing 1.3 to reduce friction and shaking between the inner shaft sleeve and the inner shaft sleeve cavity.

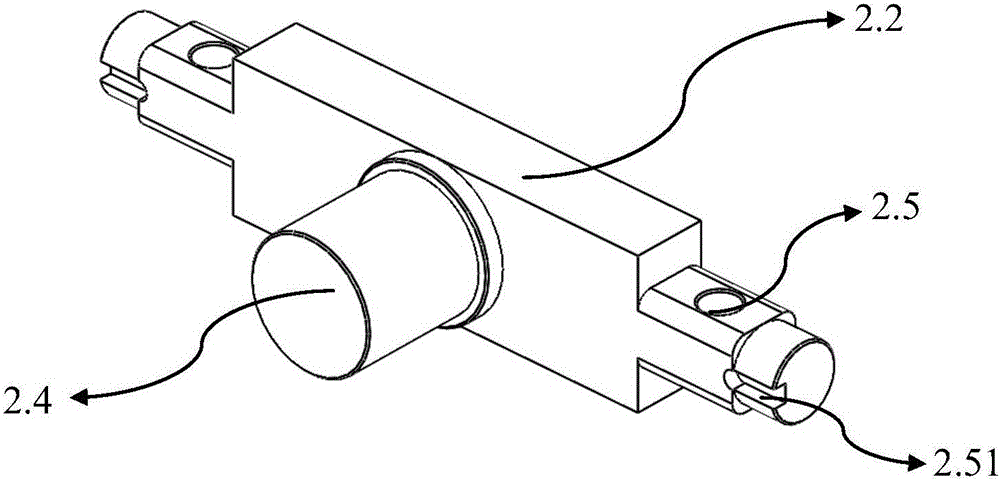

[0025] The outer plate 2 is connected by two transverse connecting plates 2.1 and two longitudinal connecting plates 2.2 to form a rectangular structure. The transverse connecting plate 2.1 has an inner bushing cavity formed therein, and the outer side of the longitudinal connecting plate 2.2 is provided with an outer bushing. The two ends of the longitudinal connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com