Automatic decorating machine for Chinese New Year cake production

A printing machine and automatic technology, applied in the field of food manufacturing, can solve the problems of low printing efficiency, large instability, and uneven finished product effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

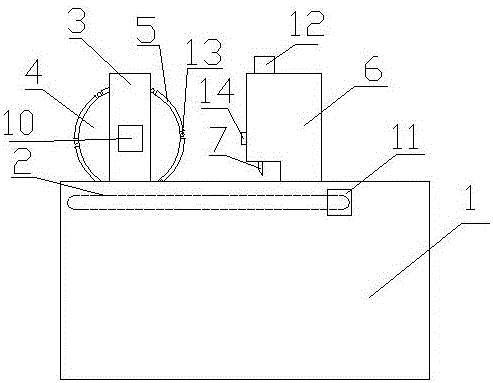

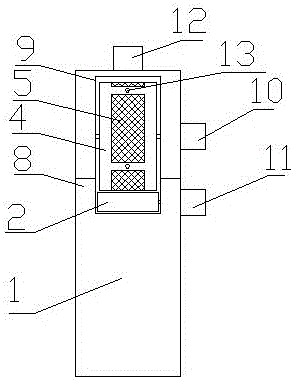

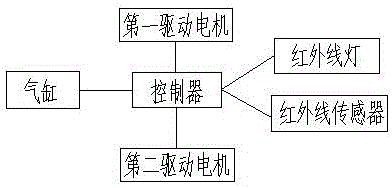

[0018] Combine below Figure 1 to Figure 3 , to further describe the technical solution of the present invention, but not limited to this description.

[0019] An automatic printing machine for rice cakes, comprising a machine platform 1, on which a conveyor belt 2 is provided, side walls 8 are provided on both sides of the conveyor belt 2, the length of the side walls 8 matches the length of the conveyor belt 2, and the conveyor belt 2 is connected There is a first driving motor 10, the machine table 1 is provided with a first frame 3, the first frame 3 includes a roller groove 9, the groove walls on both sides of the roller groove 9 are respectively connected to the two side walls 8 correspondingly, and the roller groove 9 There is a roller 4 inside, and the roller 4 is located above the conveyor belt 2. A number of stamps 5 are uniformly arranged on the wheel surface of the roller 4, and there is a gap between every two adjacent stamps 5. The roller 4 is connected with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com