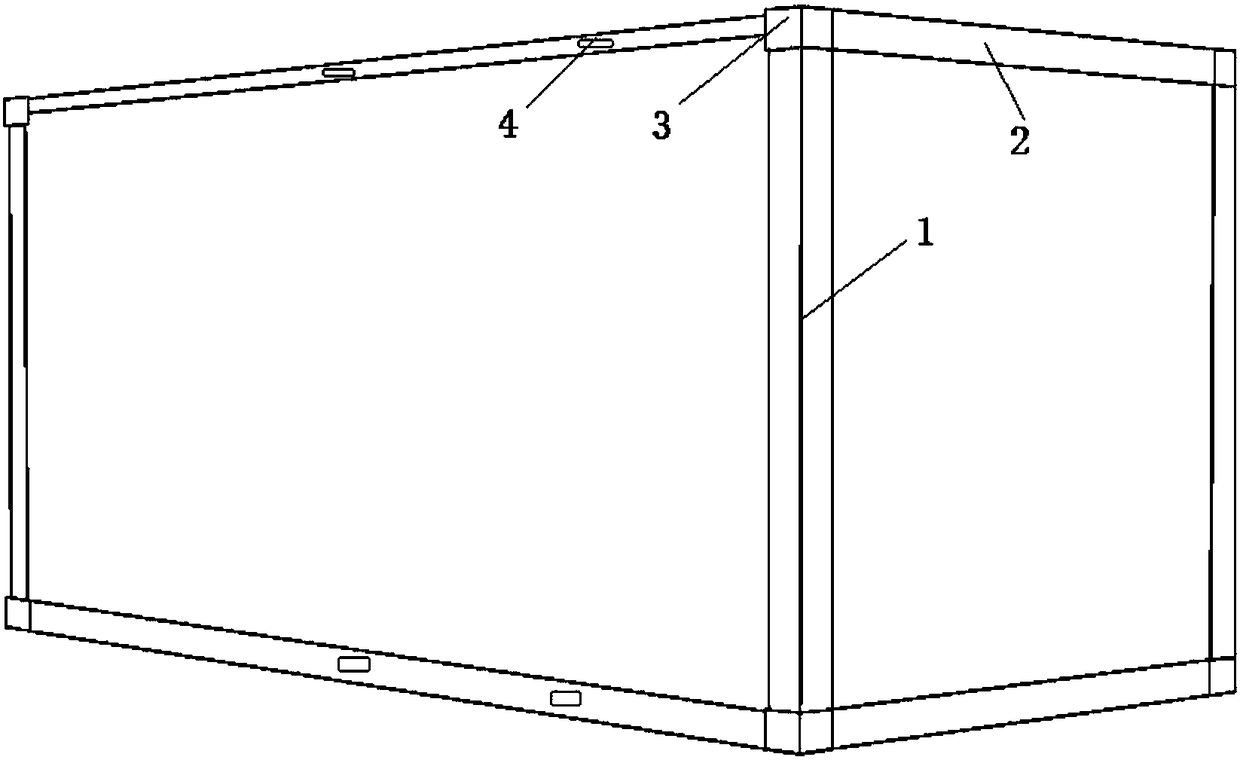

modular house

A modular and housing technology, applied in construction, building components, fire prevention, etc., can solve the problems of many internal space design restrictions and unacceptable problems, and achieve the effects of good structural stability, high industrial productivity, and improved safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

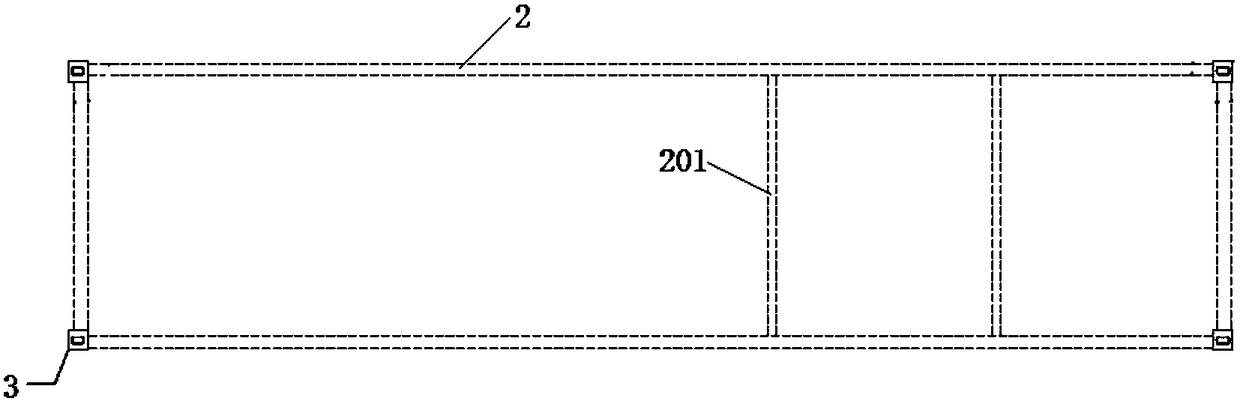

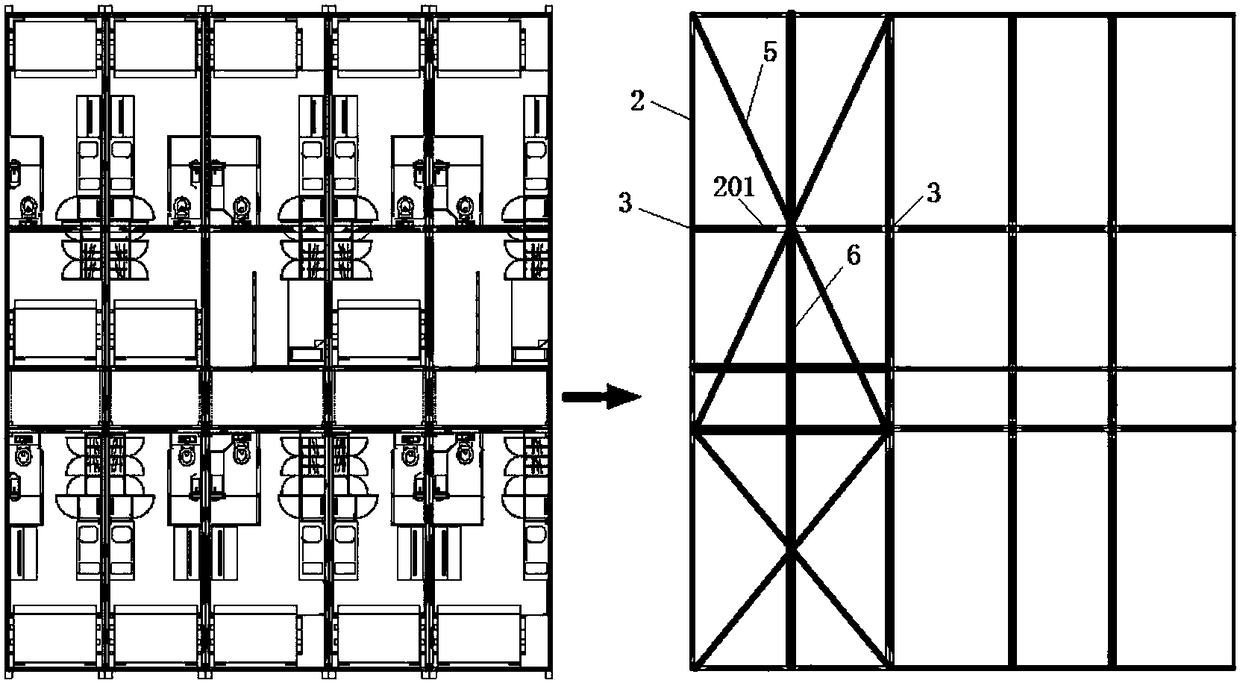

[0074] The modular house provided according to the present invention includes a main column, a main beam, a corner piece and a detachable wall, the main column is a vertical bearing mechanism, the main beam is a horizontal bearing mechanism, and adjacent Between the main beam and the main column, between the adjacent main beam and the main beam, can be fastened and connected by corner fittings, the wall is installed in several planes surrounded by the main column and the main beam, and the wall There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com