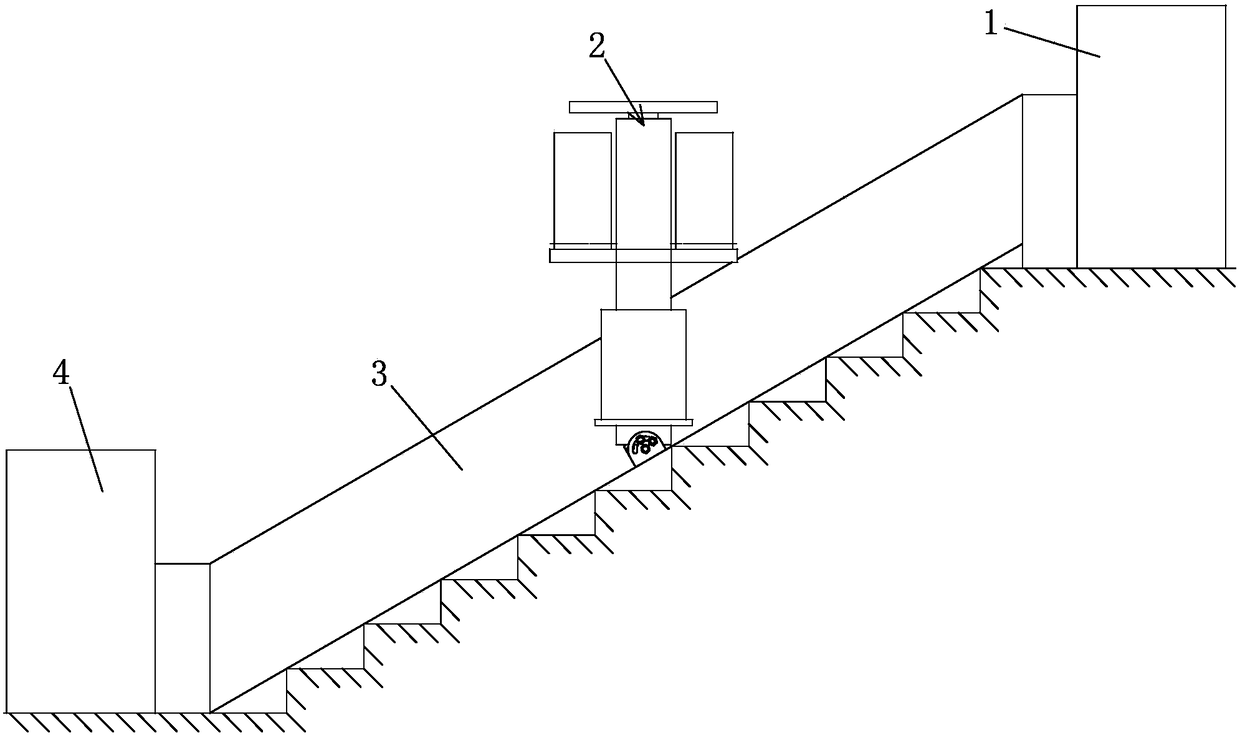

a stairway elevator

A corridor elevator and corridor technology, applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of multi-corridor space, inconvenient, inconvenient observation of seat obstacles or other conditions, and avoid potential safety hazards , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

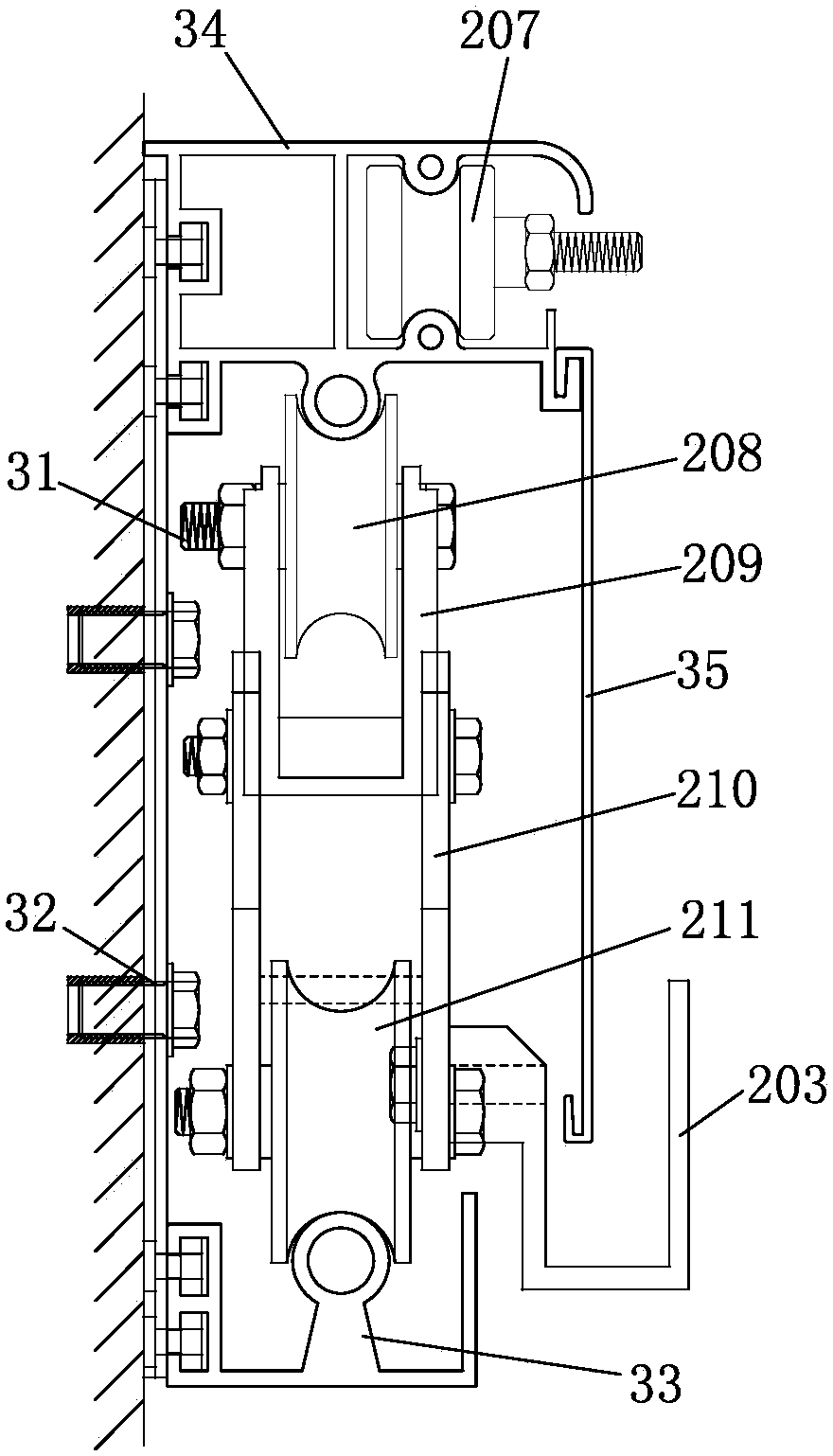

[0050] In other embodiments, for example, between the rail wheel base 210 and the rail wheel frame 209, the sliding up and down can be adjusted through the slide groove, and can be locked and fixed by fasteners or wedges.

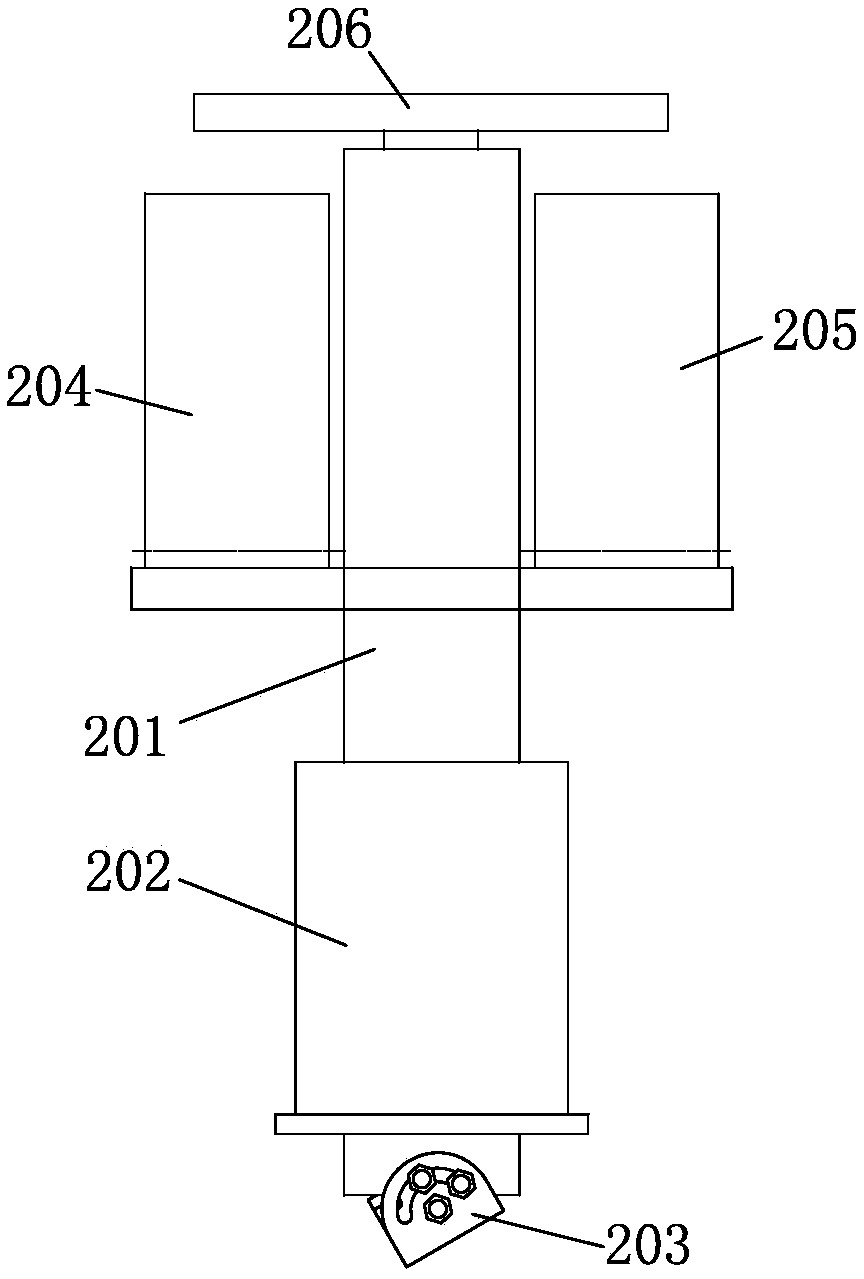

[0051] Such as Figure 8 , Figure 9 , Figure 10 The track wheel seat 210 shown is a casting, and its two side walls 2101 are connected as a whole through two connecting parts up and down. Two third U-shaped track wheels 211 are installed between the two side walls 2101 through holes 2104, and the connecting piece 203 passes through Three holes 2103 are fixed on the outer side wall. Such as Figure 11 , Figure 12 The track wheel frame 209 shown is a casting, and its two side walls 2091 are connected as a whole by the lower connection part, and the second U-shaped track wheel 208 is installed between the two side walls 2091 through the hole 2092, and on the side wall of the track wheel frame 209 The flange 2094 is formed with a guide chute (the guide ...

Embodiment approach

[0055] In a preferred embodiment, the motor 42 is a servo motor, and the wire winding drum 41 is connected to the rotating shaft 43 through a spline.

[0056] Such as image 3 As shown, when the above corridor elevator is installed on site:

[0057] First install the track box 3: first install the first U-shaped track wheel 207 in the track groove of the upper track frame 34, and then pass the upper track frame 34 and the lower track frame 33 through the upper connector 36, the lower connector 37 and a plurality of connections. The plates 31 are fixedly connected to form the track box 3 erected in the direction of the slope of the corridor. The multiple connecting plates 31 of the track box 3 are fixed on the corridor wall by fasteners 32, and the control cabinets 1 and 4 are fixed in the corridor and Connect with track box 3;

[0058] Install track wheel set again, the track wheel set of track car is put into track box body 3, by adjusting the position of track wheel frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com