An electric rotary drive for high row seats

A technology of electric rotation and drive, which is applied to seats, railway car body parts, transportation and packaging, etc., and can solve the problems of not installing electric rotation drives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

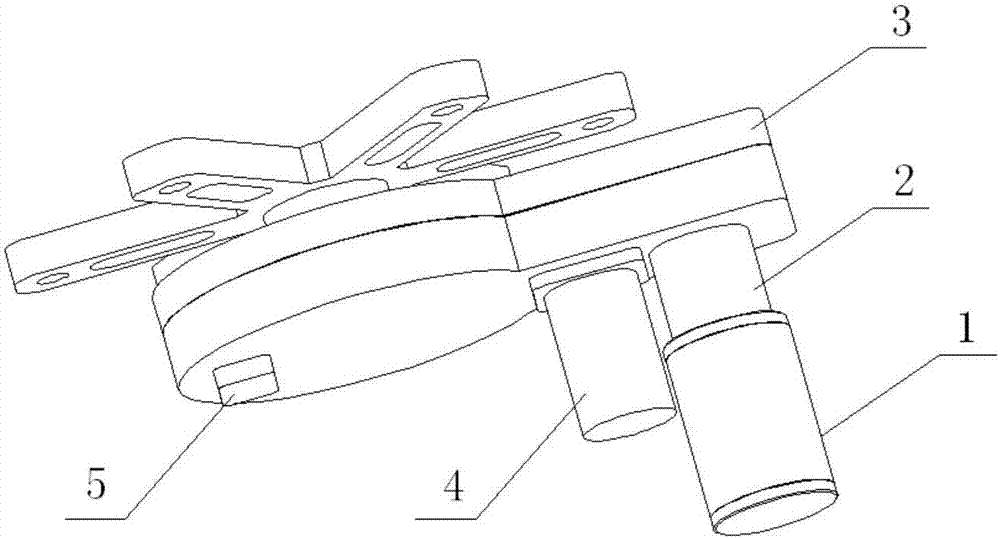

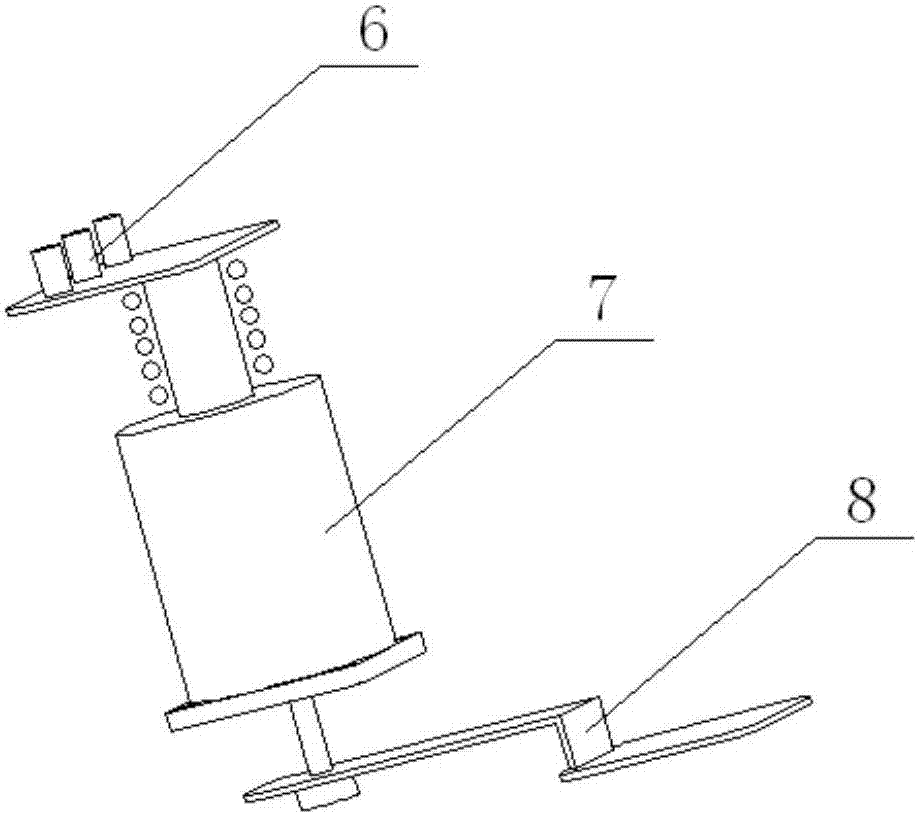

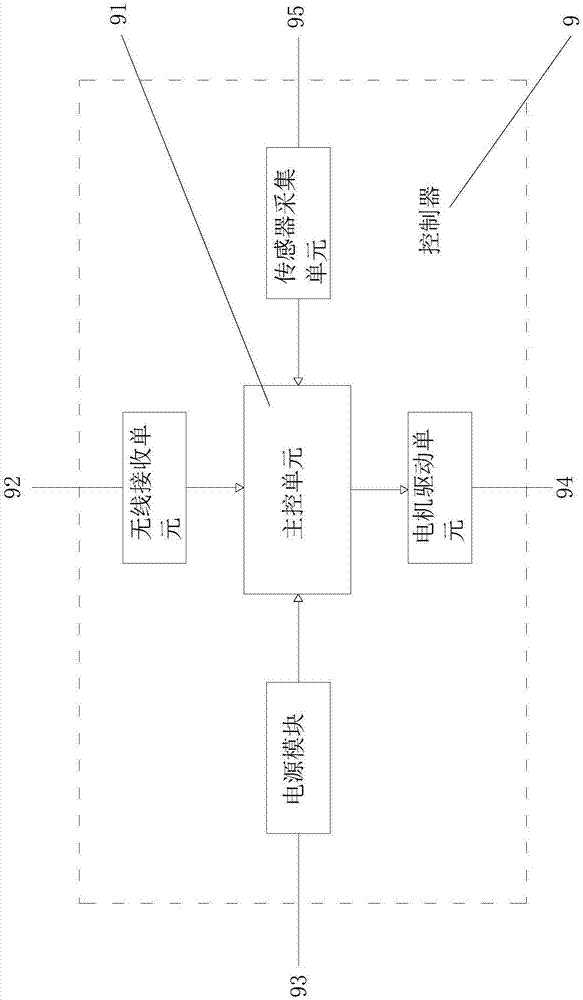

[0015] Please refer to Figure 1 to Figure 3 , an electric rotary driver for high-row seats, including a DC motor 1, a reducer 2, a transmission mechanism 3, a small electric clutch 4, a sensor 5, a large electric clutch 7 and a controller 9, and the transmission mechanism 3 is installed On the chair frame of the high-row seat; the output shaft of the DC motor 1 is connected in rotation with the transmission mechanism 3 through the reducer 2, and the small electric clutch 4 is installed on the transmission mechanism 3, and the small electric clutch 4 is small when it is not powered on. The electric clutch 4 and the transmission mechanism 3 are in the disengaged state and the two are in the combined state when the small electric clutch 4 is powered on, the sensor 5 is installed on the transmission mechanism 3, and the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com