Intelligent production management method for signal equipment maintenance

A technology of intelligent production and management methods, applied in data processing applications, instruments, resources, etc., can solve problems such as insufficient dispatch and tracking of temporary tasks, insufficient tracking, and inconsistency, etc., to improve the quality of production operations and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

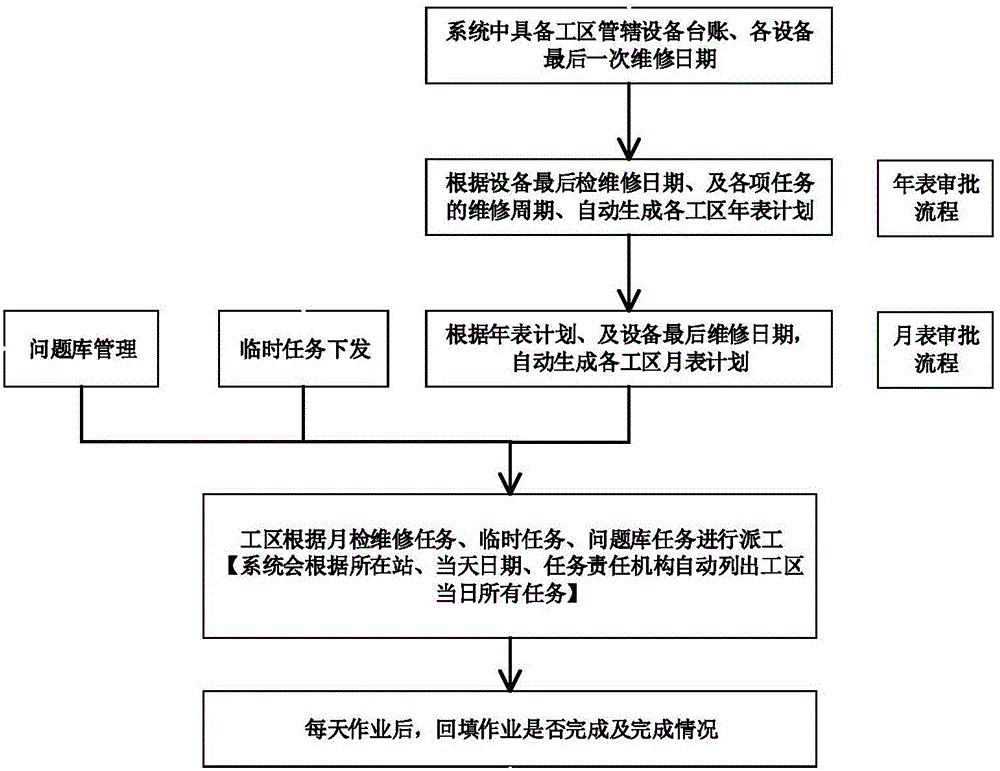

[0031] Such as figure 1 As shown, an intelligent production management method for signal equipment maintenance includes the following steps:

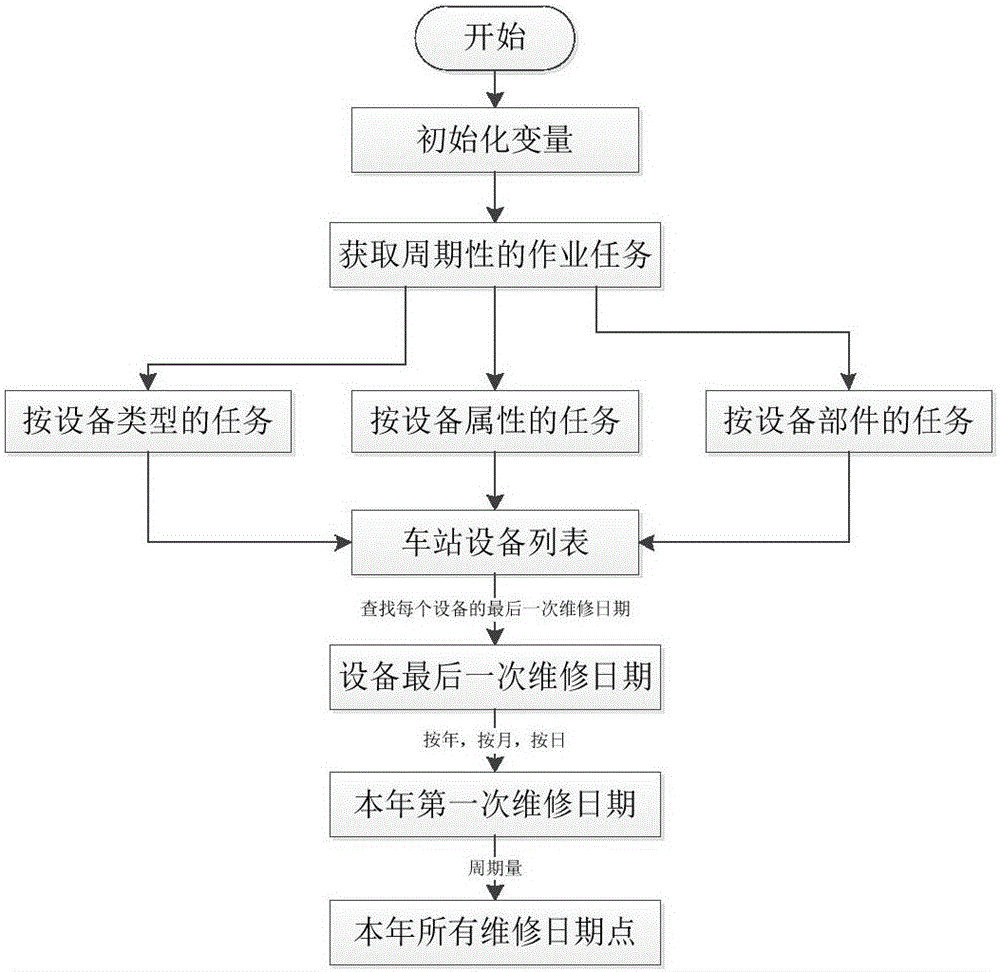

[0032] 1) According to the final maintenance time and maintenance cycle of the equipment in the railway bureau's electrical section, the annual schedule is automatically generated through the traversal analysis algorithm.

[0033] 2) Make manual adjustments to the generation year schedule.

[0034] 3) The monthly schedule is automatically generated according to the annual planned tasks and the last maintenance time of the equipment.

[0035] 4) Realize the issuance and transfer of temporary tasks. (The system automatically provides tasks whose responsible organization is the work area to the work area to be dispatched list).

[0036] 5) The data of the question bank subsystem is automatically included in the production management. (The system automatically provides a list of issues to be dispatched to the work area for which the age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com