Action method of fully hydraulic autonomous moving mechanical arm

An autonomous mobile and robotic arm technology, applied in the field of robotic arms, can solve the problems of serious vulcanization pollution, high labor intensity, and occupational health hazards of workers, achieve huge market value, improve workers' occupational health level, and meet the needs of large-scale mobile operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

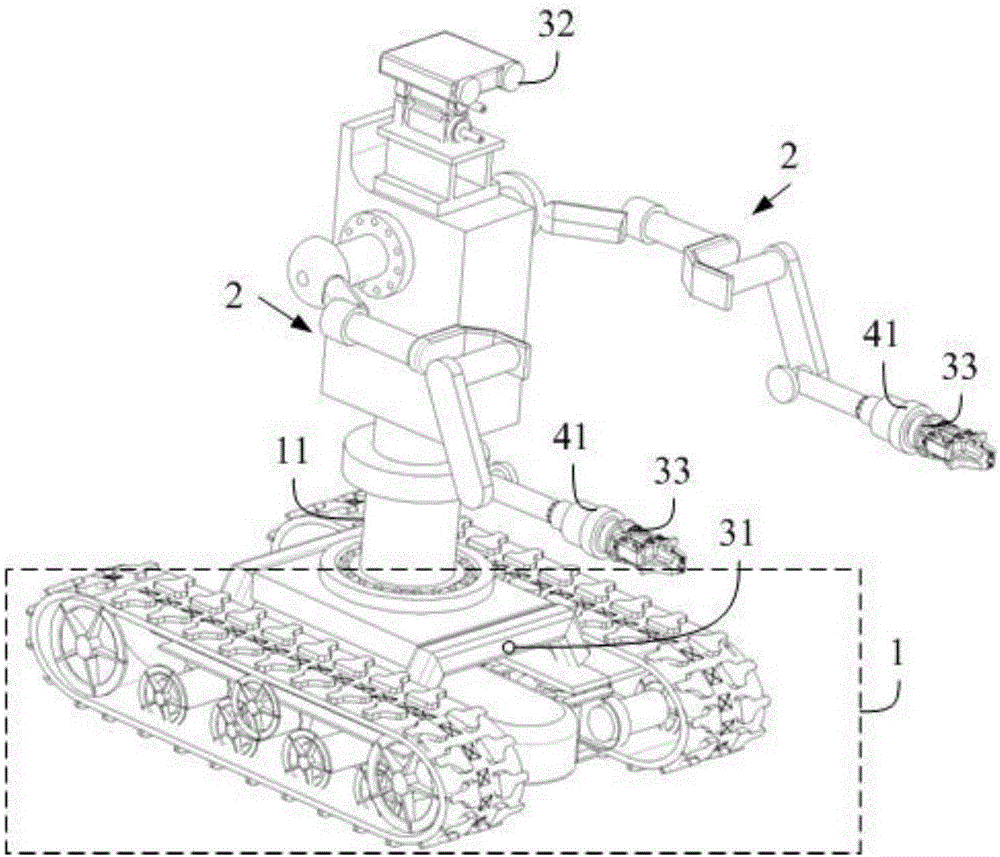

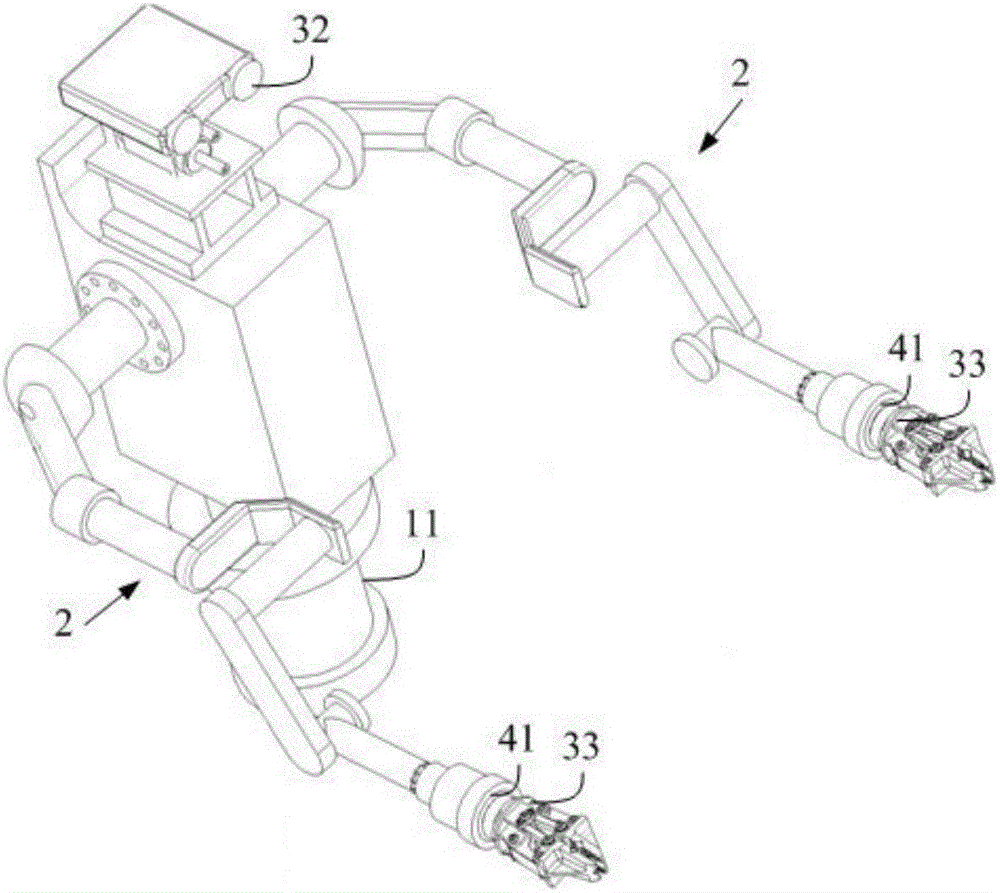

[0042] On the one hand, the present invention provides a kind of fully hydraulic self-moving manipulator, such as Figure 1 to Figure 2 As shown, the omnidirectional mobile platform 1 is included, and the omnidirectional mobile platform 1 is provided with a double robot arm 2, a power system, a vision system, and a perception and control system, wherein:

[0043]The omnidirectional mobile platform 1 is provided with a rotating waist device 11, and the double mechanical arm 2 is arranged on the omnidirectional mobile platform 1 through the rotating waist device 11. The double robotic arm 2 is a humanoid double arm structure with multiple degrees of freedom;

[0044] The power system adopts engine-hydraulic drive mode;

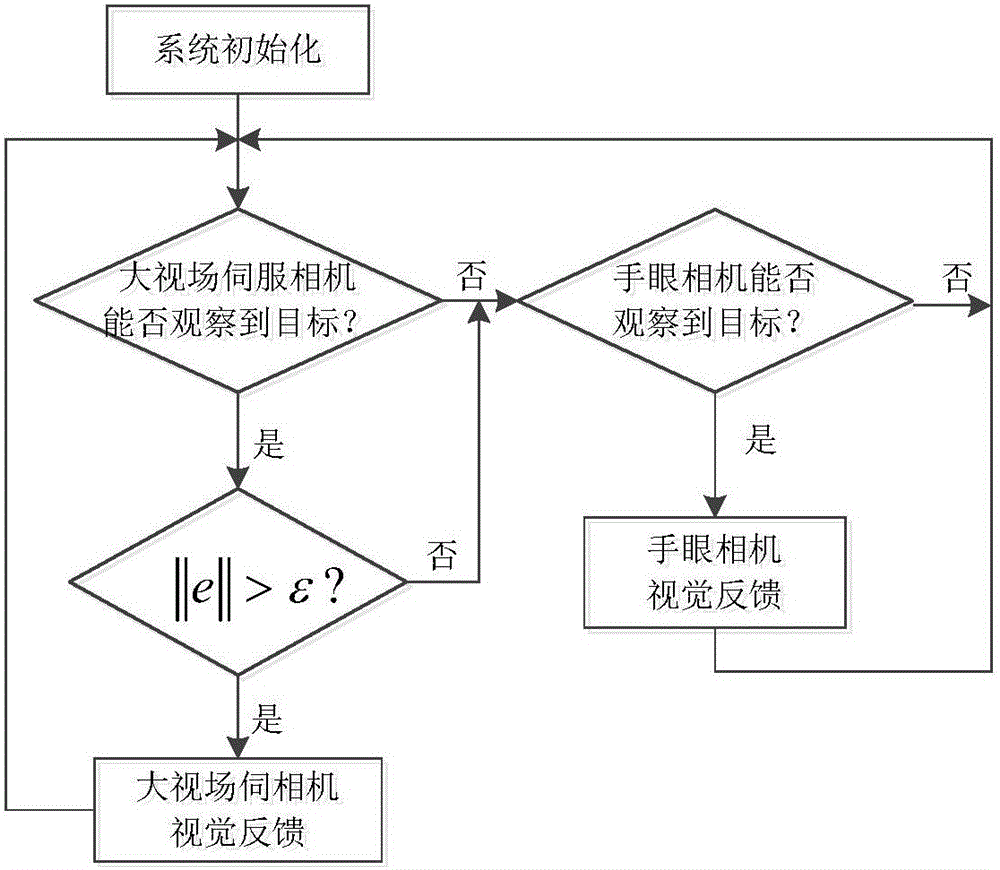

[0045] The visual system includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com