Double ended led tube light

An LED tube lamp, double-ended technology, which is applied in the direction of lampshade, cooling/heating device of lighting device, lighting and heating equipment, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

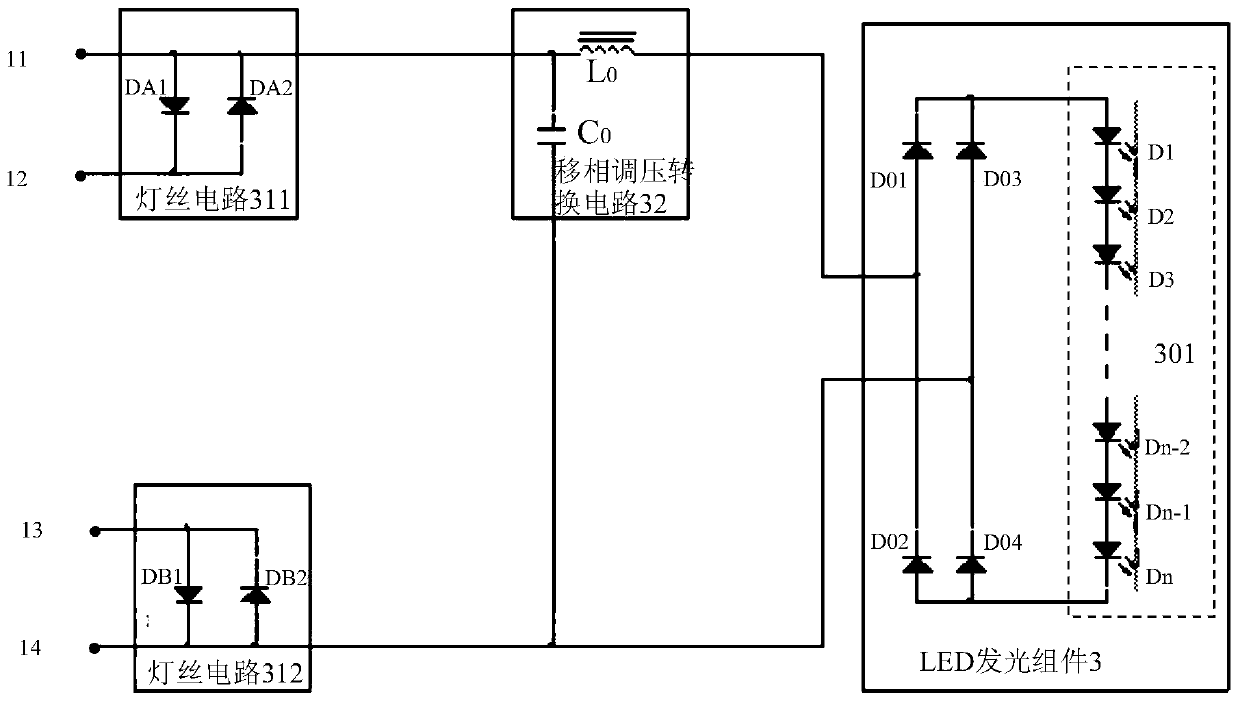

[0040] see figure 1 , the double-ended LED tube lamp of the present invention is an LED tube lamp replacing a fluorescent tube, which includes:

[0041] Lamp cover 5 is a circular tubular two-color PC cover. Its front side is a light-emitting surface 51, and its back side is an opaque surface 52. Viewed from the cross-section, the arc of the light-emitting surface 51 is 220°, and the arc of the opaque surface 52 is 140°; its external dimensions are exactly the same as the replaced fluorescent tube (diameter, length, etc.), and can directly replace the fluorescent lamp of the same specification Tube.

[0042] The heat-dissipating aluminum profile 4 is placed in the lamp cover 5 with a groove 41 in the middle, and two symmetrical slots 42 are arranged on both sides of the groove 41 .

[0043]The aluminum subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com