Annular lifting tool

A spreader and ring technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of many structural components, complex assembly, asymmetry, etc., and achieve the effect of improving the safety factor, facilitating adjustment, and increasing the included angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

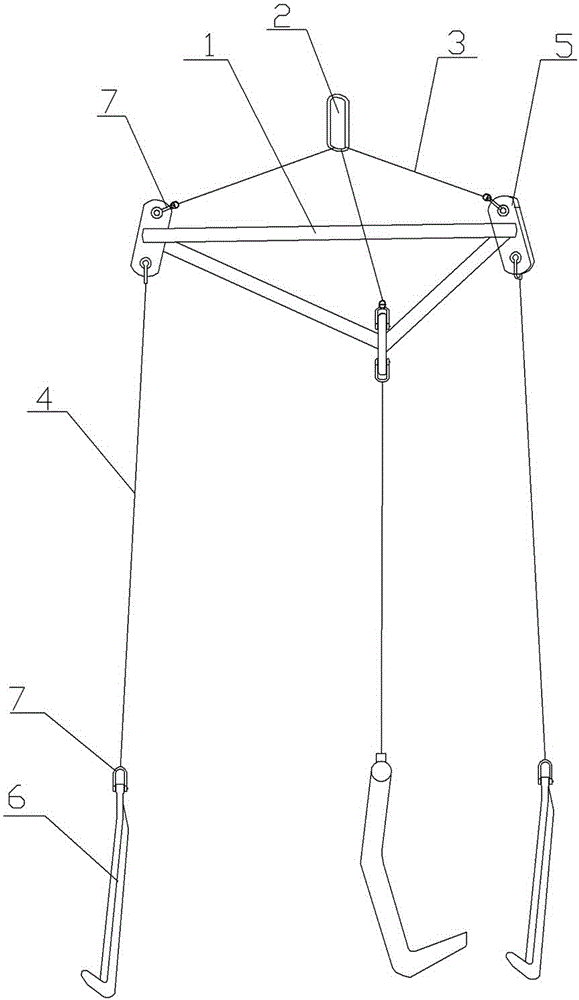

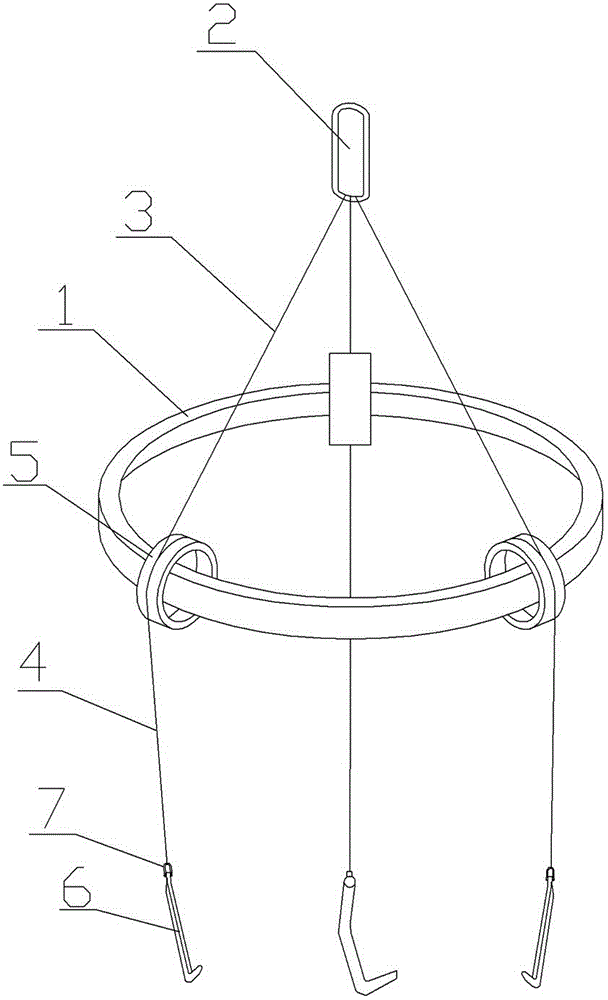

[0011] Such as figure 2 As shown, the present invention includes an annular connector 1, a suspension ring 2, an upper sling 3, a lower sling 4, a roller 5, and a hook 6. There are three upper slings and lower slings 4 respectively, and the roller 5 is movably socketed on the annular connector. 1, there is a gap between the inner ring of the roller 5 and the outer wall of the annular connector 1, so that the roller 5 can move anywhere on the annular connector 1, and the lower end of the upper sling 3 surrounds the outer wall of the roller 5 to hang The lower end of the cable 3 wraps around the roller 5 and then extends to the lower sling 4 for hanging. The height needs to be adjusted arbitrarily, and the consistency during work is enhanced; the lower end of the lower sling 4 and the hook 6 are connected through a shackle 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com