Screw multi-channel automatic feeding and installing integrated machine

An automatic feeding, all-in-one technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that screws are difficult to achieve automatic feeding, sorting and assembly, and achieve accurate and efficient automatic feeding of screws and speed up assembly. process, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

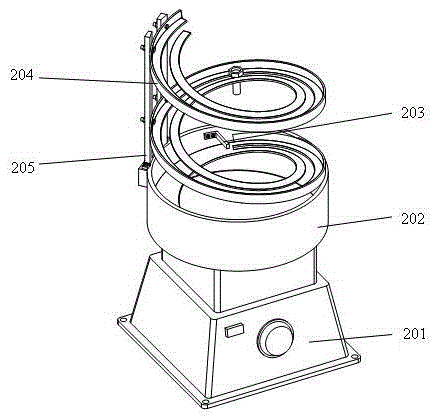

[0032] like figure 1 , including a support frame 1, a spiral vibrating feeder 2, a screw separating device 3, a screw conveying channel 4, a vertical feed transmission system 5, a screwdriver tightening mechanism 6, a workpiece clamping and positioning system 7, and a base 8, wherein the spiral vibration The feeder 2 is placed in the positioning groove of the support frame 1, and the spiral vibrating feeder 2 is fixedly connected with the screw separating device 3 through the grooved spiral feeding track 204, and the screw separating device shell 301 is connected with the vertical feeding system 5. The support frame is fixedly connected through threads, the workpiece clamping and positioning system 7 is fixedly connected with the base 8 through threads, the vertical feed transmission system 5 is fixedly connected with the base 8, and the screwdriver tightening mechanism 6 is fixedly connected with the vertical feed transmission system 5 through threads One end of the screw con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com