Ship propulsion mechanism

A technology of propulsion mechanism and ship, applied in the direction of rotary propeller, rotary propeller, etc., can solve problems such as inability to adapt to various propeller speeds, poor elimination of hub eddy current, etc., to achieve high practical value, increase propulsion efficiency, and improve propulsion The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

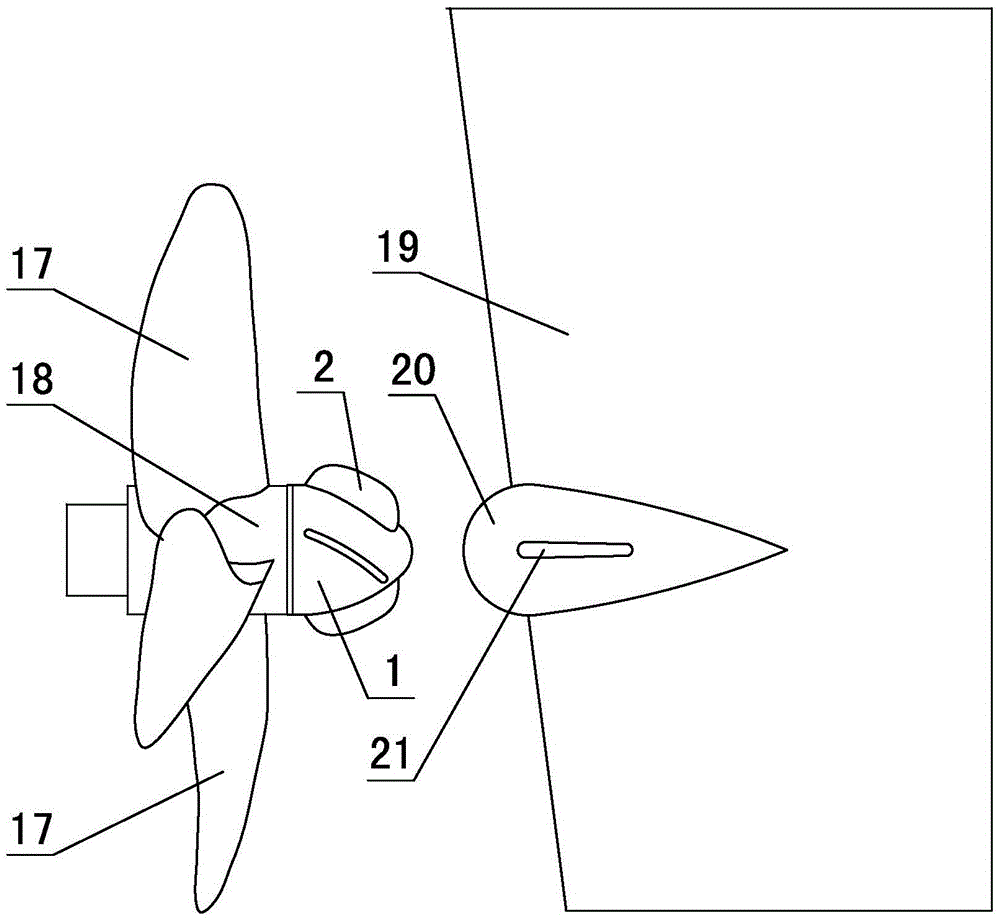

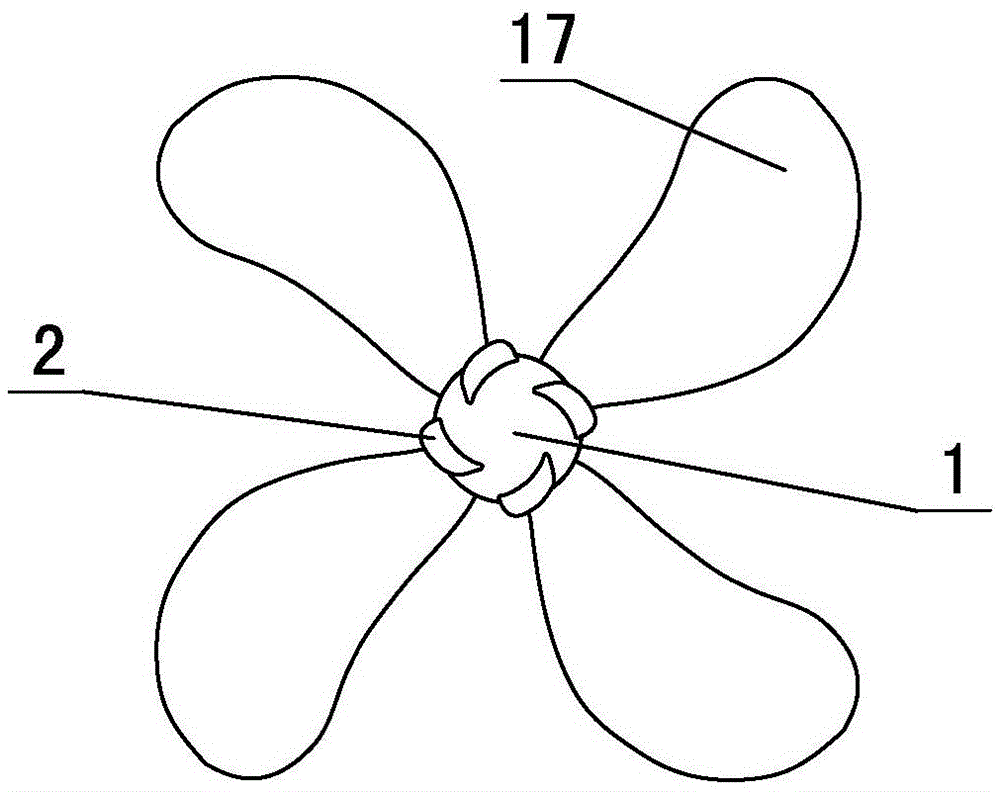

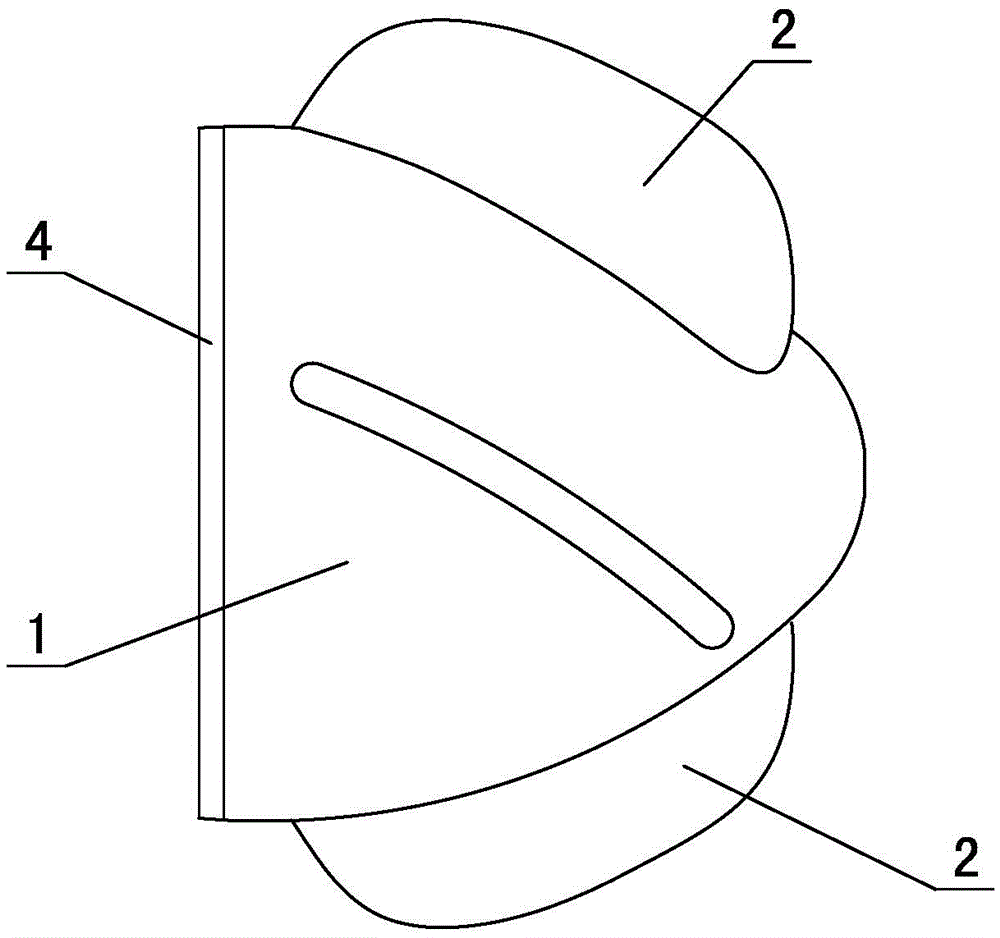

[0028] in such as figure 1 , figure 2 , image 3 In shown embodiment 1, 1. a kind of ship propulsion mechanism comprises propeller and ship rudder, and described propeller comprises propeller hub 18 and 4 blades 17, and propeller hub is provided with propeller cap, and propeller cap shell The diameter of the installation end of the rudder is equal to the diameter of the propeller hub, and the relative position of the rudder 19 and the propeller cap is provided with a rudder ball 20, and the diameter of the rudder ball is 1.2 times of the maximum diameter of the propeller cap shell, and the rear part of the rudder ball Gradually shrink to form a tapered structure, two booster wings 21 are arranged on both sides of the rudder ball in the horizontal direction, symmetrically arranged on both sides of the rudder ball, the height of the booster wings is 40% of the diameter of the rudder ball, and the length of the booster wings The degree is 1.2 times the diameter of the rudder b...

Embodiment 2

[0032] The limiting grooves of embodiment 2 are 5 straight grooves, and the center line of the limiting groove and the line between the two ends of the limiting groove and the center of rotation of the fixed plate form an obtuse triangle (see Figure 8 ), the outer edge of the fin plate is provided with a side strip 13 with a circular cross section (see Figure 9 ), the diameter of the side bar is 3 times the thickness of the fin plate, and the rest are the same as in Example 1.

[0033] The fin plate of the propeller hub cap of the present invention is provided with a rotating shaft, and the rotating shaft is connected with a deflection mechanism. When the rotation speed of the propeller is different, the deflection mechanism can provide different deflection angles, so that the helix angle of the fin plate can be adjusted automatically according to the rotation speed of the propeller. Adjustment, thereby solving the problem that the fixed fin plate on the propeller cap of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com