A method of tiling

A tiling and tiling technology, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve the problems of low degree of automation, low tiling efficiency, high manpower and time, etc., to improve accuracy and uniformity, the effect of tiling is neat and beautiful, and the effect of improving tiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

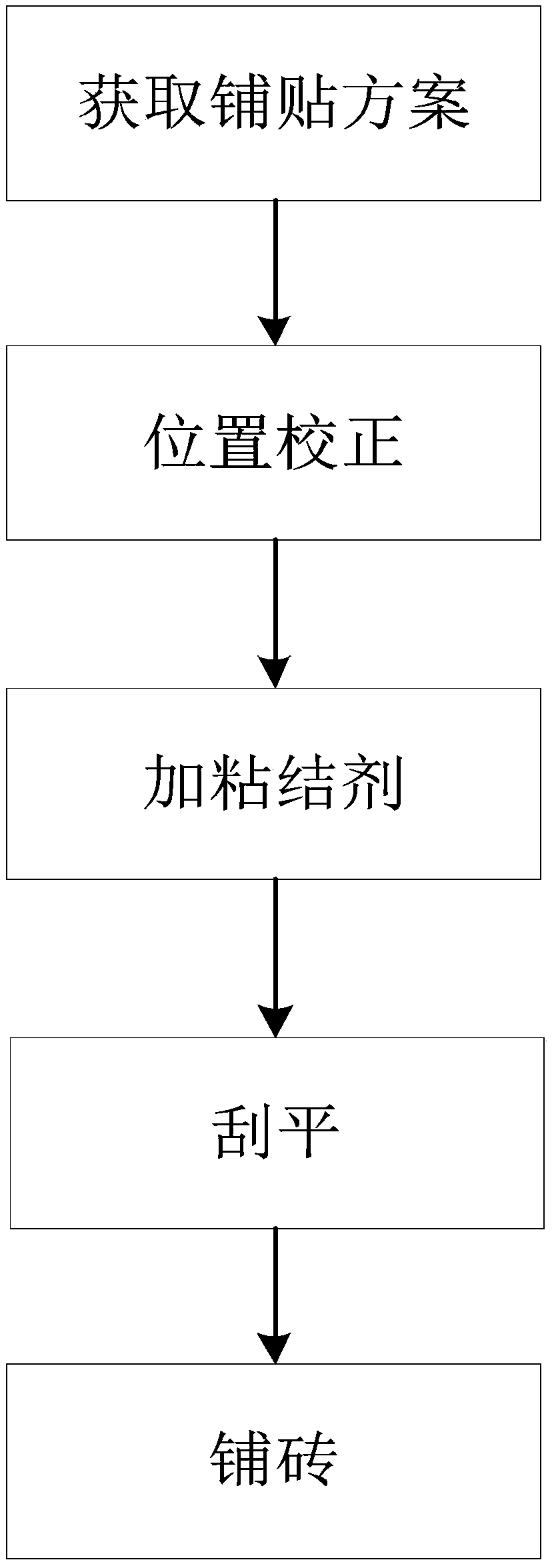

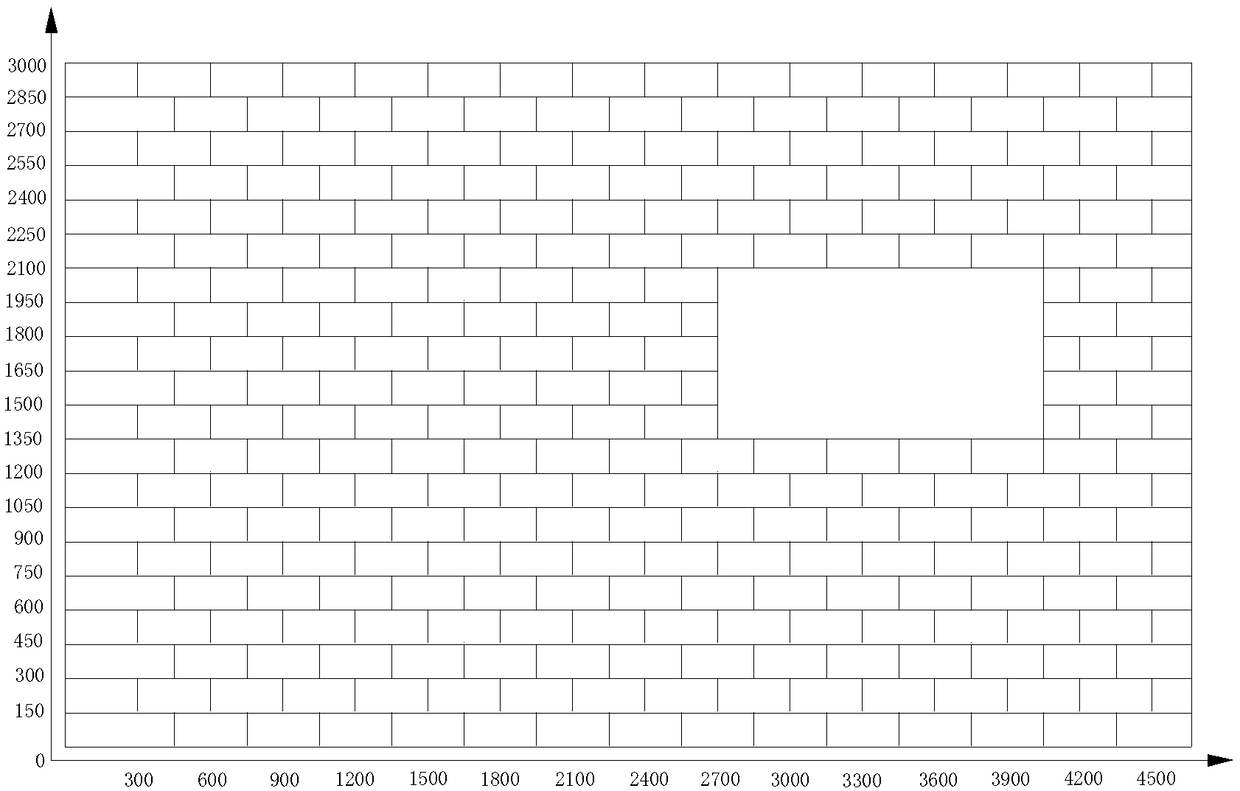

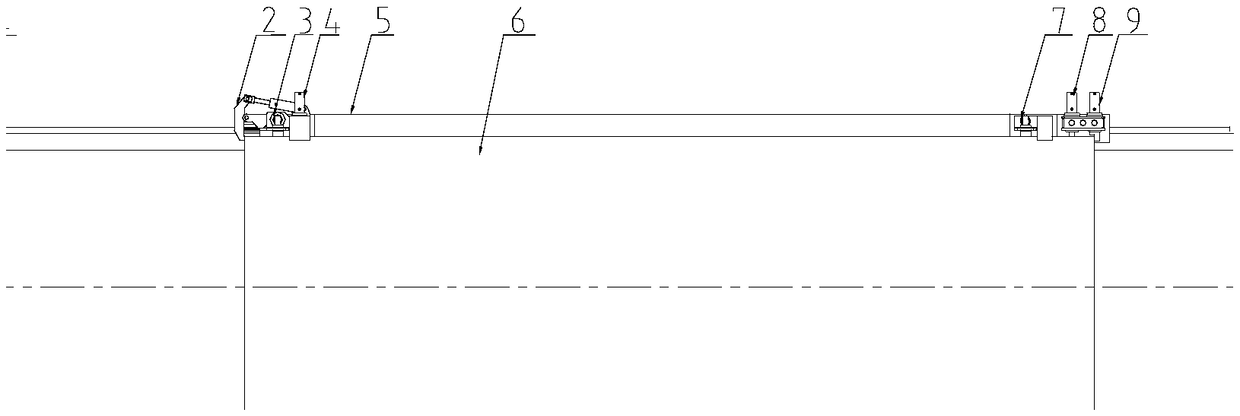

[0037] The embodiment of the present invention discloses a method for tiling tiles. During the production process of prefabricated parts that need to be tiled, the part 5 to be tiled is a prefabricated panel. Lay the tiles before construction. Through the method disclosed in the invention, according to specific needs, the paving and pasting of the prefabricated parts can be completed before leaving the factory, and compared with the traditional paving and past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com