Single-cell subnanoscale motion control system based on nanoscale micromanipulation

A motion control system, sub-nano-level technology, applied in control/regulation systems, mechanical control devices, instruments, etc., can solve the rare problems of single-cell motion control systems, and achieve space saving on the stage, wide range, and motion control Sophisticated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

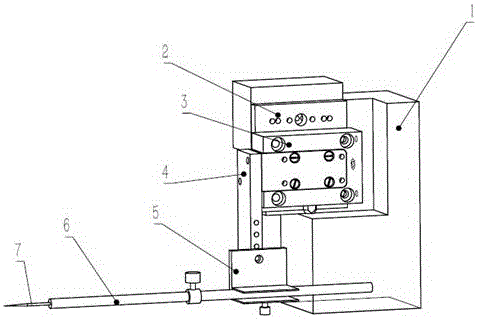

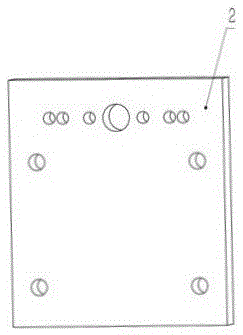

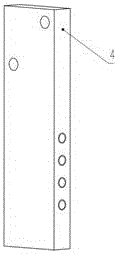

[0024] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a micromanipulation platform 1, a first adapter plate 2, a single-axis sub-nanometer positioning system 3, a second adapter plate 4, a probe holder fixture 5, a probe holder 6 and a probe 7.

[0025] The micro-operation platform 1 is fixed on the stage of the microscope, the first adapter plate 2 is fixed on the micro-operation platform 1 through screw holes, the back of the single-axis sub-nanometer positioning system 3 is fixed on the surface of the first adapter plate 2, and the second The upper end of the second adapter plate 4 is connected to the side of the single-axis sub-nanometer positioning system 3, the probe holder fixture 5 is fixed in the screw hole at the lower end of the second adapter plate 4, and the probe holder 6 is stuck in the probe holder In the spring slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com