A method for automatic transmission of aluminum profile stacking spacers

An aluminum profile and spacer technology, which is applied in the field of automatic stacking device, aluminum profile stacking spacer automatic transmission device, and aluminum profile automatic stacking device spacer automatic transmission field, which can solve the problem of manually placing spacers and wasting manpower and material resources. , low production efficiency and other problems, to achieve the effect of improving production efficiency and equipment automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for automatically conveying aluminum profile stacking spacers, comprising the following steps;

[0024] Step 1, the spacer 5 is placed on the spacer conveying synchronous belt 4, under the drive of the servo motor reducer 1, the spacer conveying synchronous belt 4 moves forward, and after being screened by the spacer selector 7 as a single piece, Enter the spacer delivery wheel 8, the servo motor reducer 2 10 drives the spacer delivery wheel 8 to rotate through the synchronous belt 2 9, and the spacer 5 is placed on the spacer and placed on the synchronous belt 12;

[0025] Step 2, under the drive of the servo motor reducer 3 15, the timing belt 12 is moved forward together with a single evenly spaced spacer 5, and when the end of the timing belt 12 is reached, The spacer 5 is sent into the stacking material frame, and when the spacer 5 in the stacking material frame meets the demand, the aluminum profile stacking spacer automatic transfer device stops running....

Embodiment 2

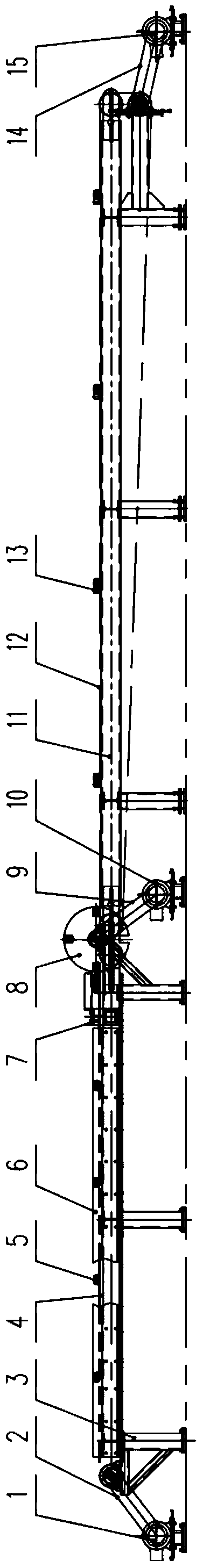

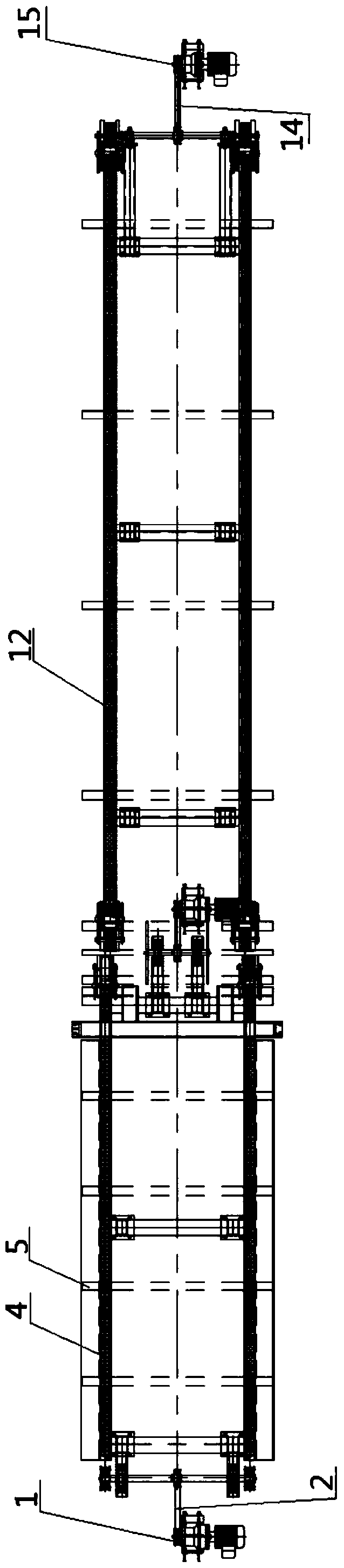

[0030] Such as figure 1 and figure 2 As shown, this embodiment provides a transmission device suitable for the automatic transmission method of aluminum profile stacking spacers, including a spacer conveying bracket 3 and a spacer placement bracket 11;

[0031] The spacer conveying support 3 is provided with two parallel spacer conveying synchronous belts 4, and the belt pulley of the spacer conveying synchronous belt 4 is driven by a servo motor reducer-1;

[0032] The spacer is placed on the support 11 and is provided with two parallel spacers to place the synchronous belt 12, and the spacer to place the synchronous belt 12 is driven by the servo motor reducer 3 15;

[0033] Between the bar delivery support 3 and the bar placement support 11, there is a bar delivery wheel 8, and the bar delivery support 3 is fixed with a bar selector 7 near the end of the bar delivery wheel 8, and the bar conveys the synchronous belt After the spacer 5 on the 4 is screened into a single p...

Embodiment 3

[0038] On the basis of Example 1, such as figure 1As shown, the spacer dispensing wheel 8 is a disk with four notches uniformly opened along the circumferential direction, and the width of the notches is greater than the width of the spacer 5 . The effect of notch is to clamp and be screened as single spacer 5 through spacer selector 7, and four notches are mutually spaced 90 degrees.

[0039] When the spacer is automatically conveyed, the spacer 5 is placed on the spacer conveying synchronous belt 4, and the servo motor reducer-1 fixed on the foundation drives the synchronous pulley fixed on the spacer conveying bracket 3 through the synchronous belt-2, driving The strip conveying synchronous belt 4 moves forward ( figure 1 middle to the right), when the spacer 5 passes below the spacer selector 7, since the spacer selector 7 can only allow one layer of spacer 5 to pass through, the spacer 5 is placed in a single layer after passing through the spacer selector 7 Yes, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com