Device for assembling stainless steel vehicle body of railway vehicle

A rail vehicle and assembly device technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems affecting the quality of car body manufacturing, personal injury, and high labor intensity, and achieve the elimination of safety hazards in the car. The cross-sectional size of the car body and the effect of avoiding damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

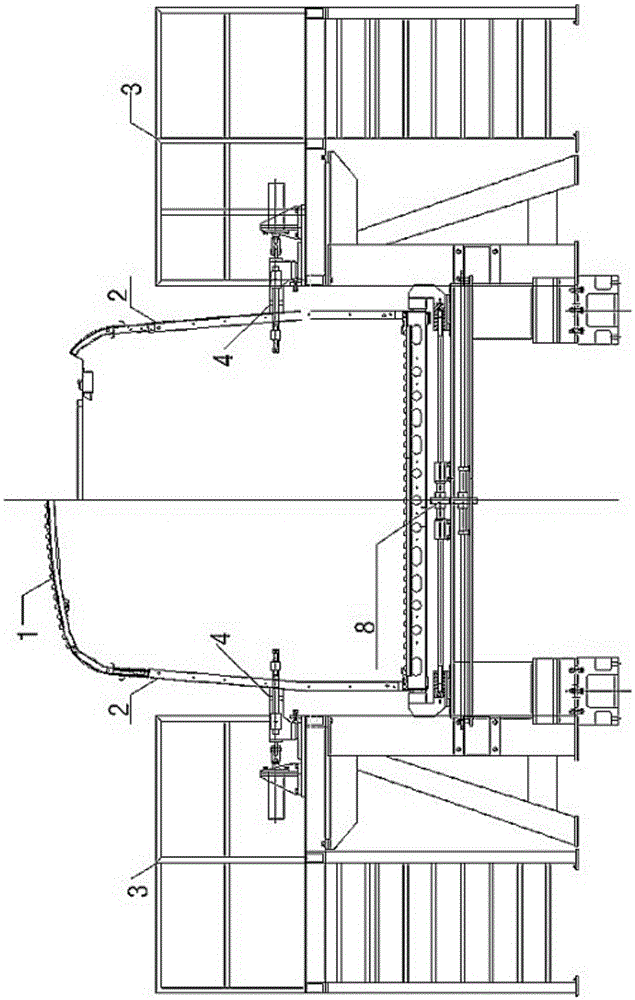

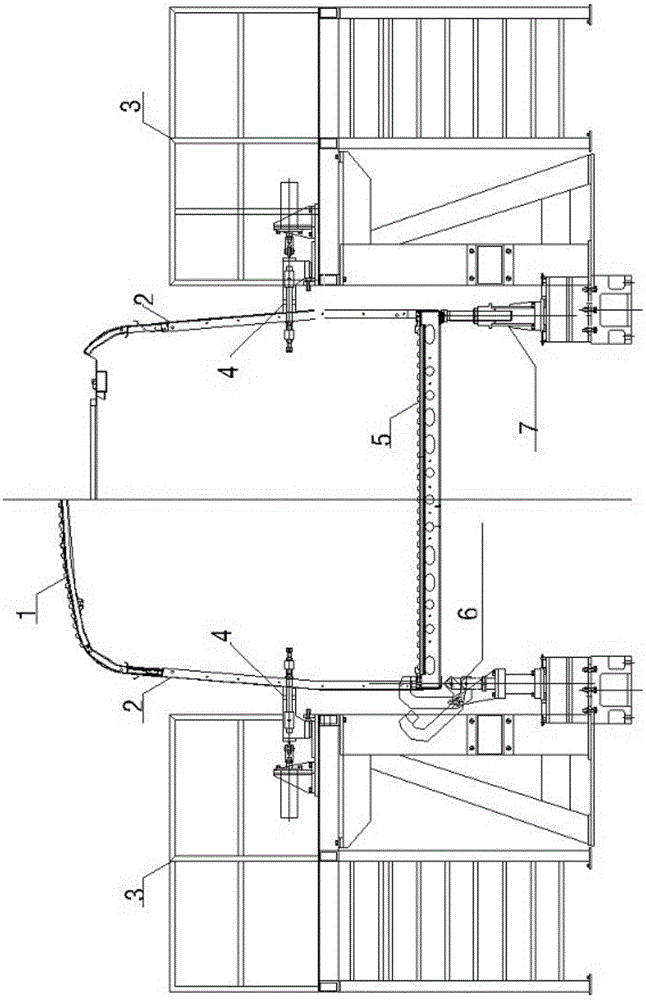

[0030] like figure 1 , figure 2 As shown in the figure: 1——roof; 2——side wall; 3——walking platform; 4——positioning and tightening device outside the side wall; 5——underframe; 6——specific trajectory arm type Tensioning device; 7—flexible supporting device of the chassis; 8—special mechanical device for centering, positioning and clamping of the chassis.

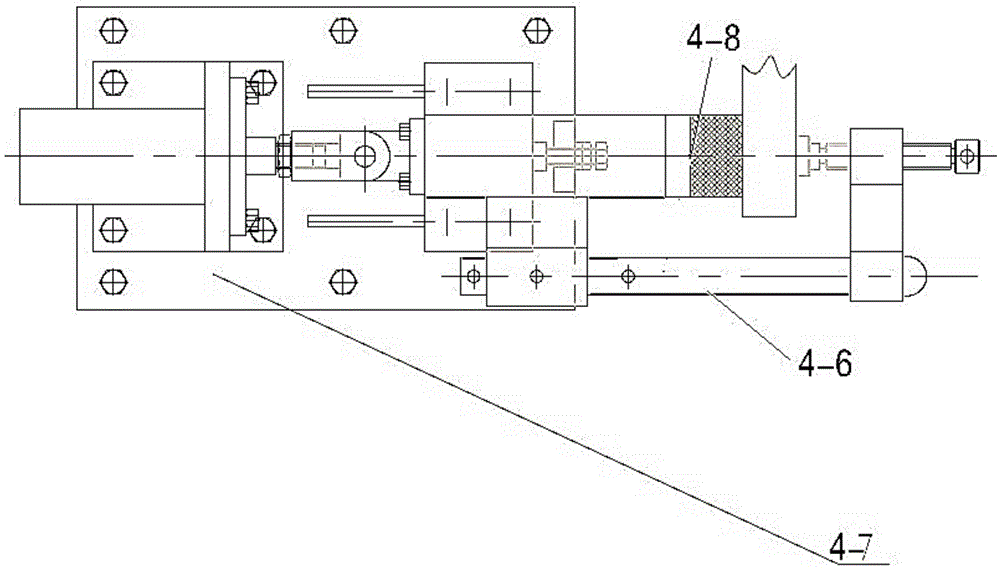

[0031] like Figure 4 , Figure 5 As shown in the figure: 4-1——horizontal oil cylinder; 4-2——oil cylinder support; 4-3——first connecting block; 4-4——sliding seat; 4-5——screw fine-tuning positioning Device; 4-6—inside fastening piece of side wall; 4-7—base; 4-8—outside positioning piece of side wall; 4-9—linear guide rail.

[0032] like Image 6 As shown in the figure; 6-1——longitudinal base; 6-2——horizontal adjustment seat; 6-3——drive shaft support seat; 6-4——pulling hook; 6-5——module; 6-6 ——...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com