Convex spot welding equipment for passenger car

A bump welding, passenger car technology, applied in welding equipment, welding equipment, resistance welding equipment and other directions, can solve the problems of low projection welding efficiency and high labor technical requirements, to improve production efficiency, improve the quality of projection welding, operation Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

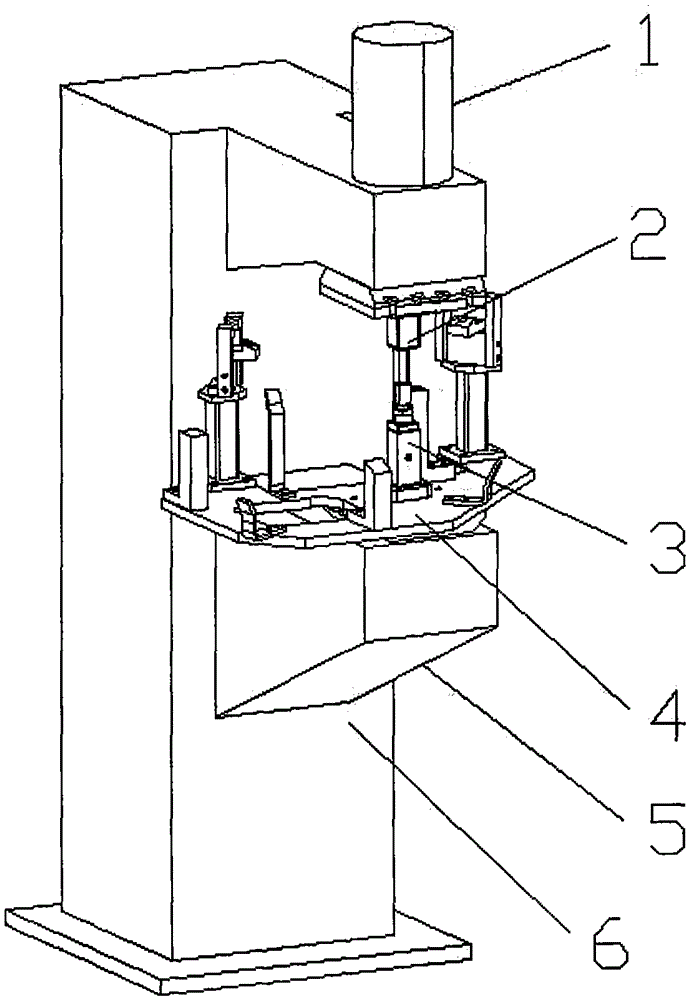

[0022] Depend on Figure 1-Figure 4 The shown bump spot welding equipment for passenger cars includes a seat spot welder body, and the seat spot welder body includes a body 6 , an upper electrode assembly 2 and a lower electrode assembly 3 .

[0023] Both the upper electrode assembly 2 and the lower electrode assembly 3 are arranged on the front side of the body 6 . The upper electrode assembly 2 and the lower electrode assembly 3 are vertically opposed to each other.

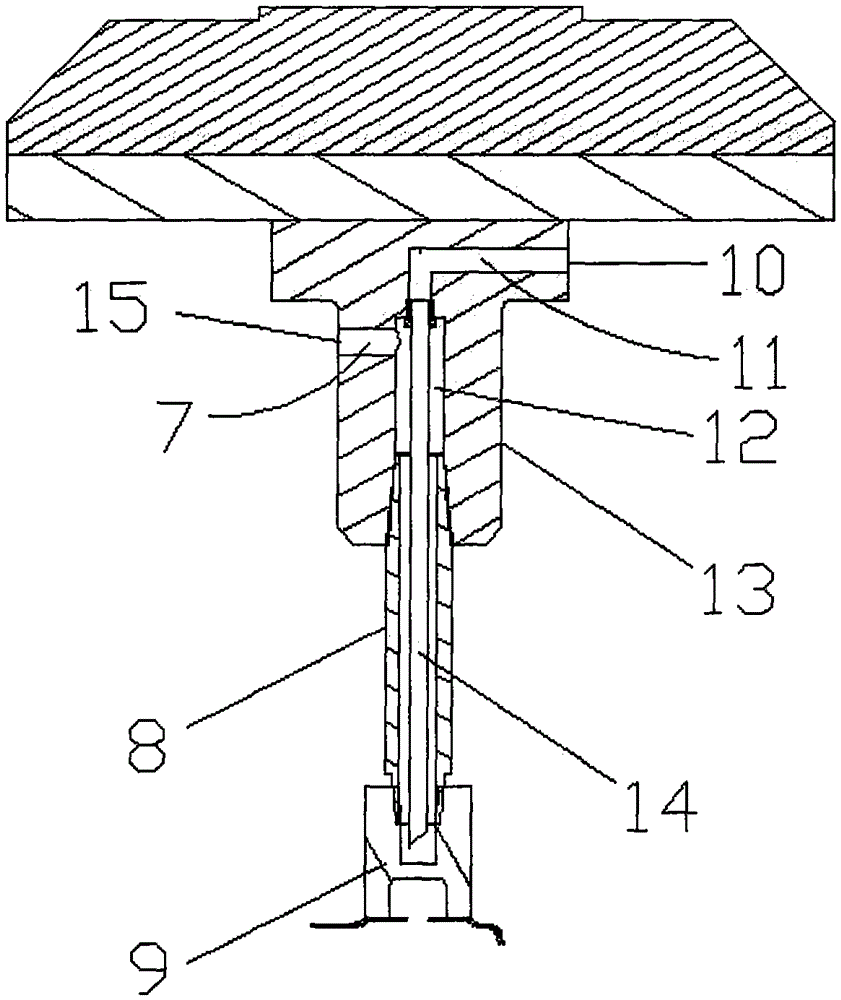

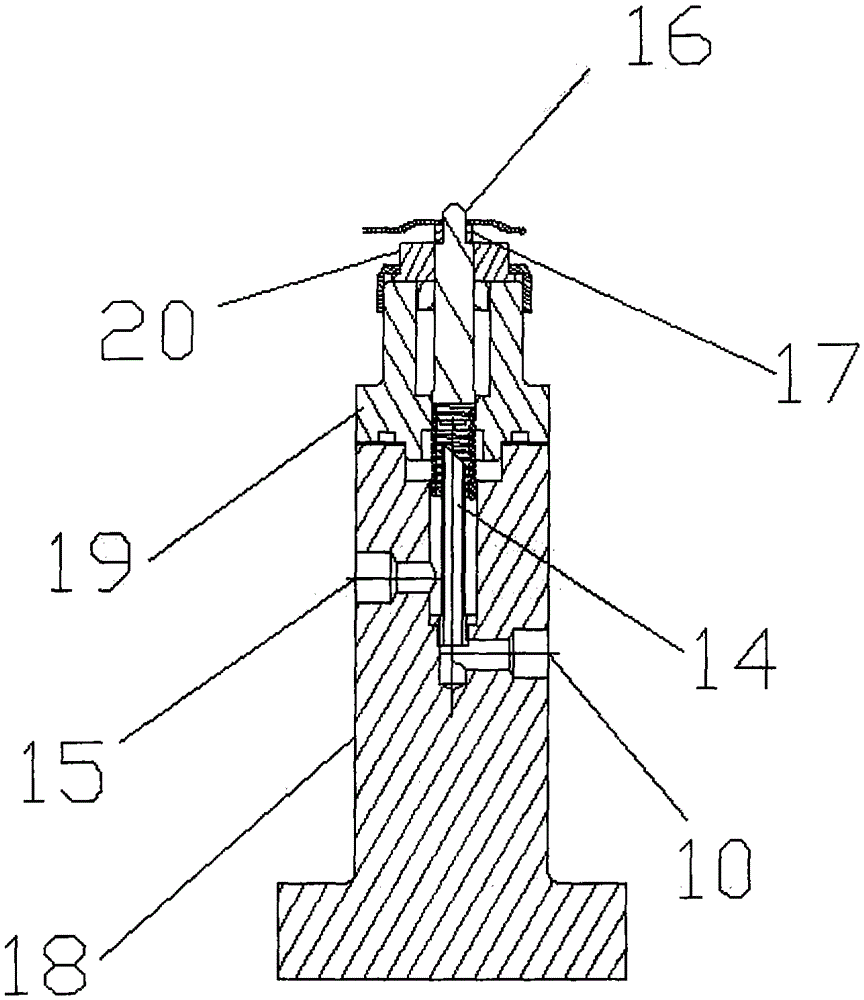

[0024] The upper electrode assembly 2 is fixed on the lower side of a guide post 1. The guide post 1 is slidably connected to the body 6 and can move up and down under the drive of the power device. When the guide post 1 moves up and down, the upper electrode assembly 2 also moves with it. Move up and down. The upper electrode assembly 2 includes an upper electrode seat, an upper electrode rod 8, an upper electrode head 9 and an upper water pipe 14, and the upper electrode seat is provided with a water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com