A structure device for direct-drive speed-up narrow-tube wind-gathering power generation

A wind-gathering and narrow-tube technology, which is applied in the field of direct-drive speed-increasing narrow-tube wind-gathering power generation structures, can solve problems that cannot be overcome and cannot be applied to severe wind conditions, and achieve simple structure, beautiful appearance, and easy installation The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

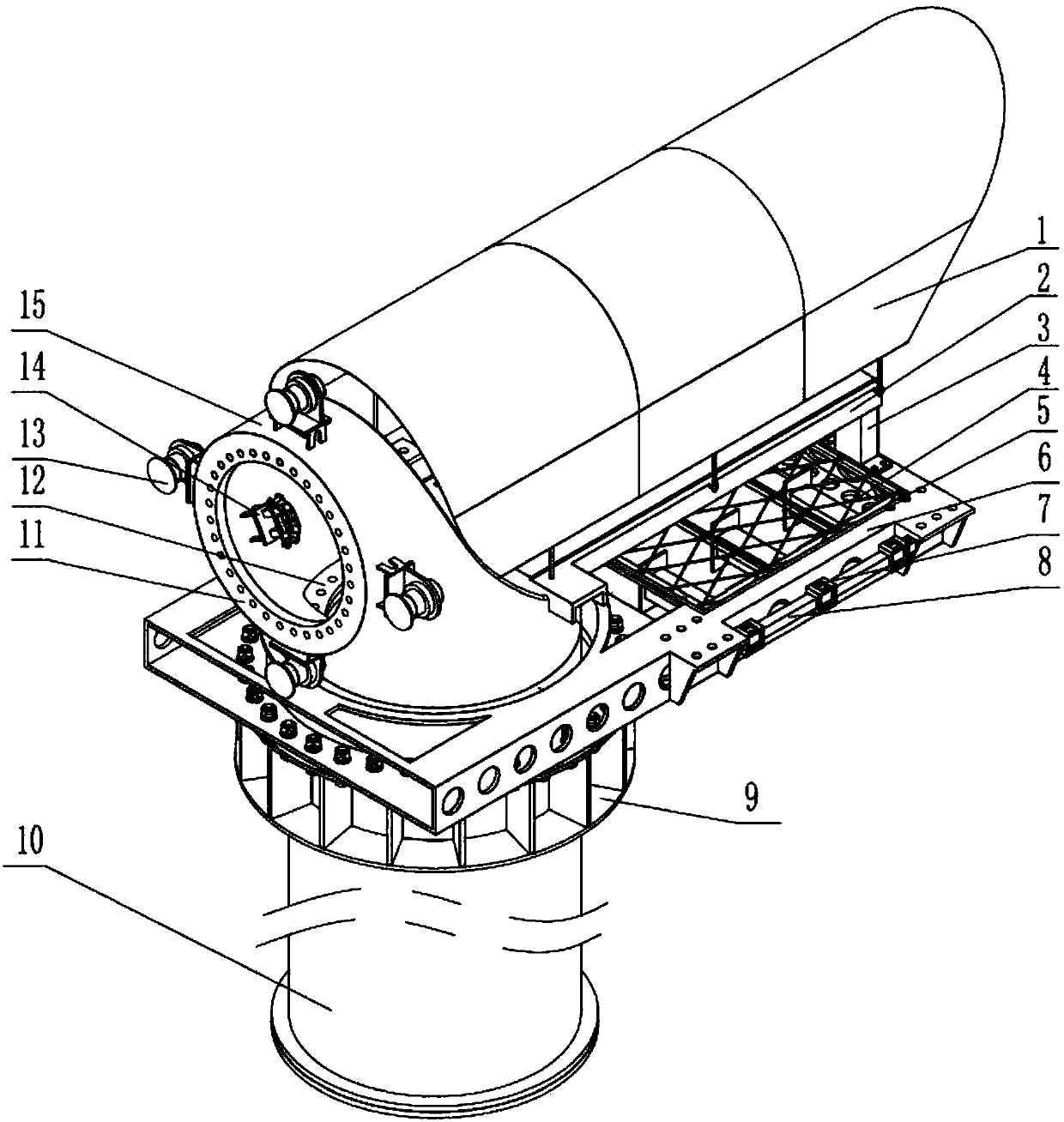

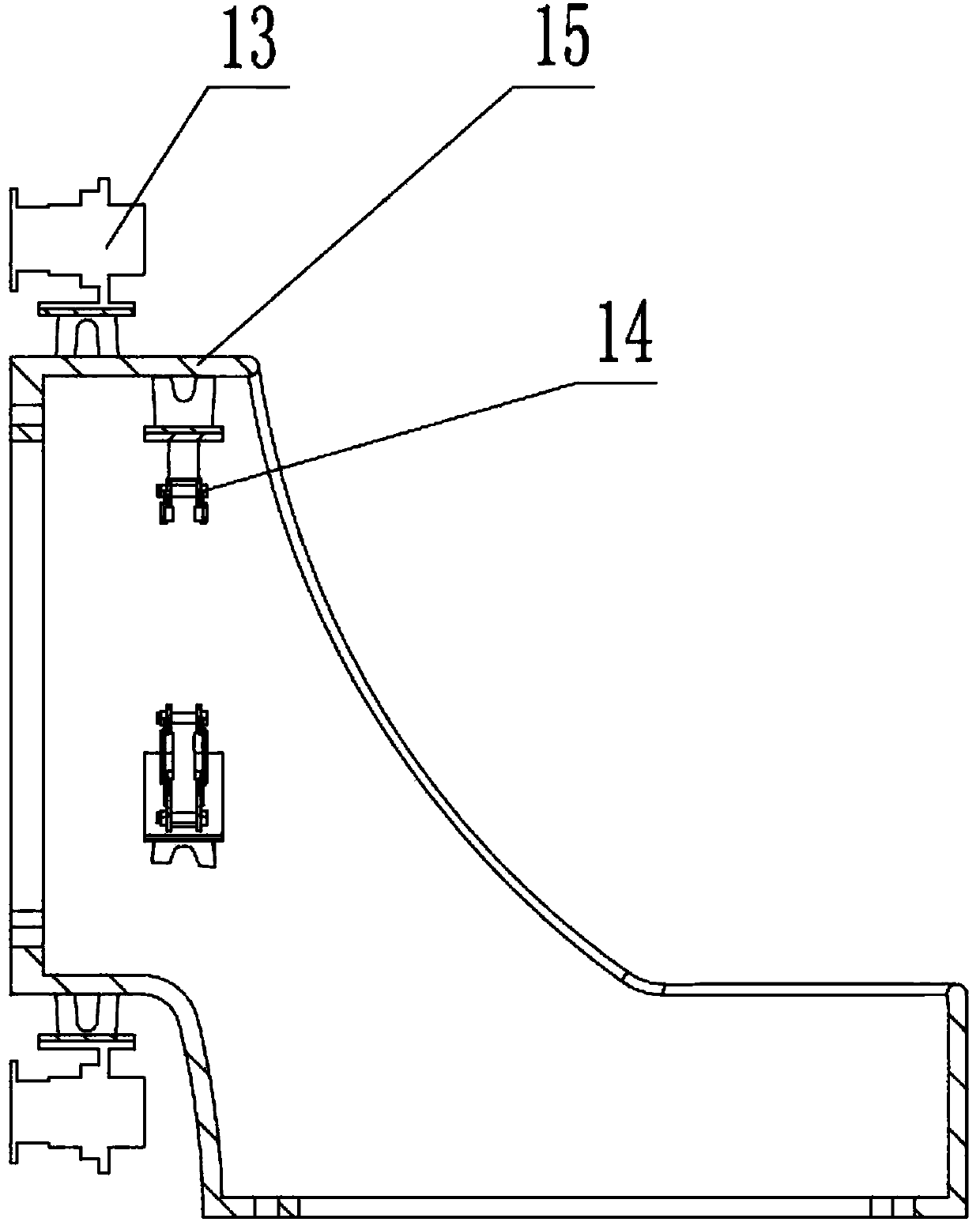

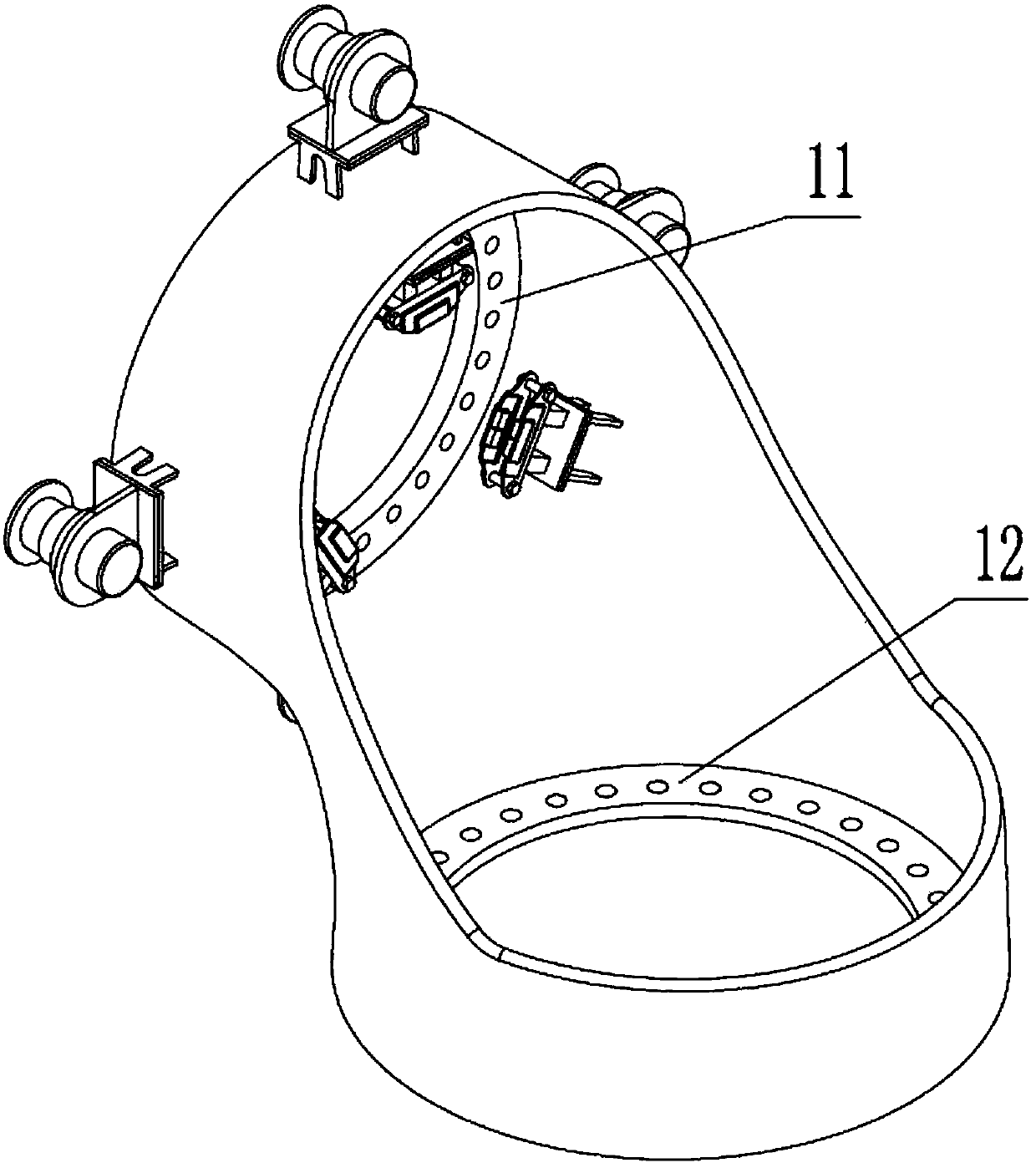

[0032] like figure 1 As shown, a frame device for direct-drive speed-increasing narrow tube wind gathering power generation includes a hub-type member 15, one end of the hub-type member 15 is affixed to the inner ring of a slewing bearing (not shown in the figure), and the hub-type member 15 The other end is affixed to one end of the tubular support 10; the outer circumference of the tubular support 10 is matched with the tubular support hoop 9, and one end of the tubular support hoop 9 is affixed with the washer 16 and the fastener to strengthen the composite bridge 6, and the double-rail structural frame One end of 2 is affixed to the tail of the reinforced composite bridge 6 , the other end of the double-track structural frame 2 is clipped to the hub member 15 , and the end connected to the tubular support 10 and the hub member 15 runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com