Two-needle clamping mechanism for dry farmland in-bowl rice seedling transplanting

A technology of needle clips and seedling needles, which is applied in the field of bowl seedling taking devices, can solve the problems of low operating efficiency, complex structure, and low-speed operation, etc., and achieve the effects of wide application range, good operating quality, and less operating failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

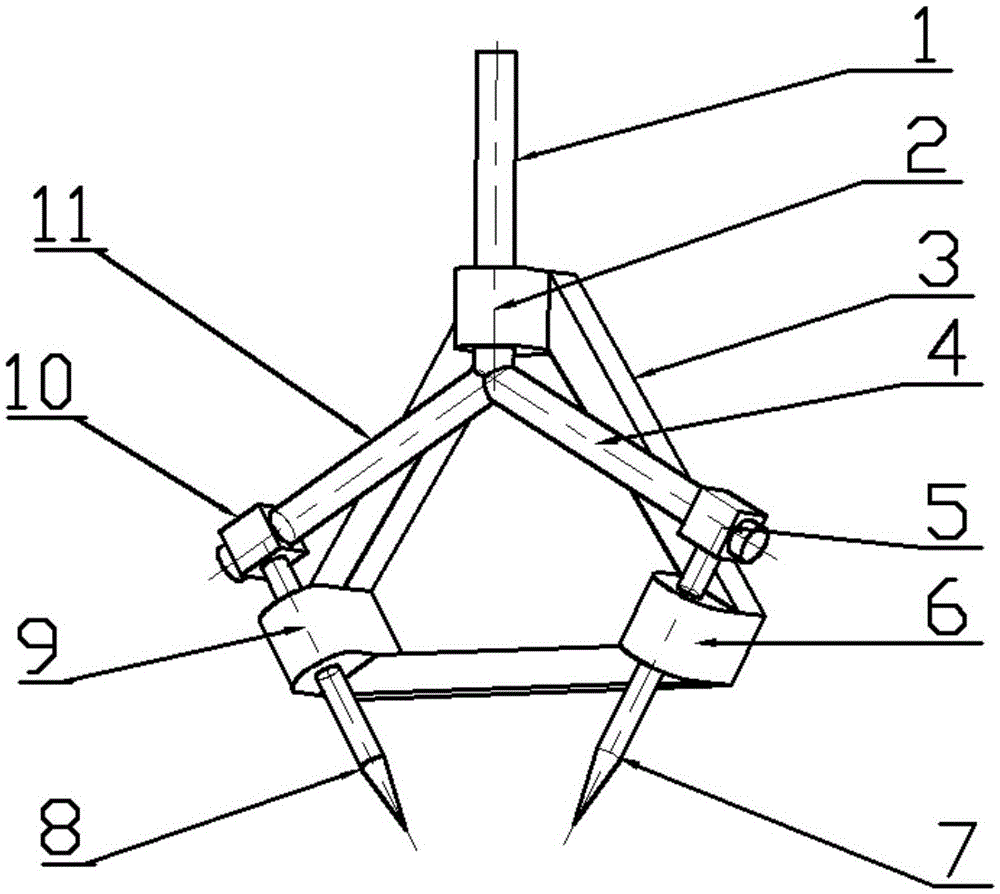

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A two-needle clamping mechanism for transplanting pot seedlings in dry fields. A rod cover 2, a left needle cover 9 and a right needle cover 6 are respectively installed on three angular parts of a triangular plate-shaped frame 3. The rod cover 2, left needle cover The axis lines of the cover 9 and the right needle cover 6 are located in the same plane; the axis line of the left needle cover 9 and the axis line of the right needle cover 6 are intersected in a "V" shape as a whole; the driving rod 1 can be axially The movable one is inserted on the rod sleeve 2, and the left oblique rod 11 and the right oblique rod 4 are mounted symmetrically on the lower end of the driving rod 1, and the left oblique rod 11 and the right oblique rod 4 are integrally formed to be low and low on the outside. The "eight" shape configuration with a high inner side, the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com