Multi-lens micro-motion device module

A micro-movement device, multi-lens technology, applied in installation, optics, instruments, etc., can solve the problems of complex optical and mechanical assembly, unclear imaging quality, low production efficiency, etc., to improve production efficiency and good rate, reduce Production process steps, the effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

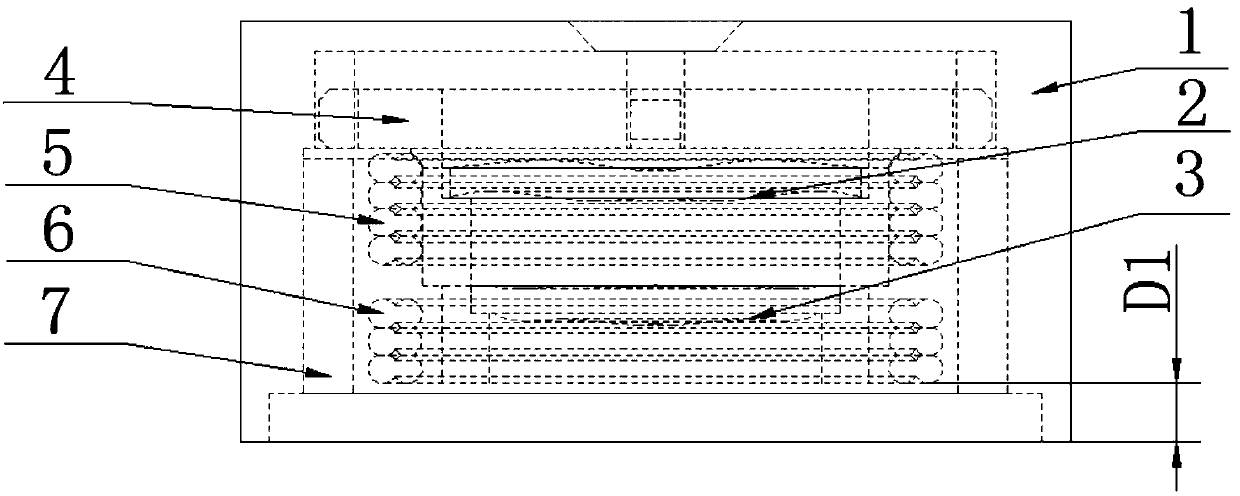

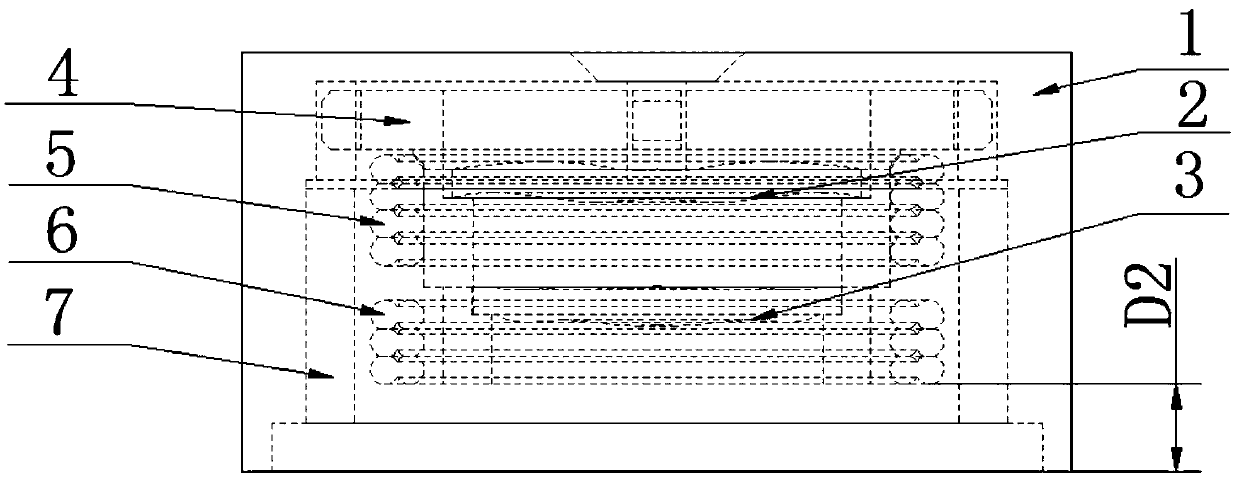

[0021] combine figure 1 As shown, it is a three-dimensional exploded schematic view of one of the structures used to realize the multi-mirror micro-motion device of the present invention. The main components used in the invention include a housing 1 , a primary lens 2 , a secondary lens 3 , a lens holder 4 , a primary coil 5 , a secondary coil 6 and a magnetic ring 7 .

[0022] The main lens 2 and the auxiliary lens 3 are embedded in the lens holder 4; the main coil 5 and the auxiliary coil 6 are respectively fixed on the outer surface and the outer surface of the lens holder 4; the magnetic ring 7 is fixed on the inner surface of the shell 1. The shell is made of plastic material and has a hollow square frame structure, and the shell has a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com