An inner-rotating grille sealing connector

A grid plate, internal rotation technology, which is applied in the direction of engine sealing, engine components, water/sludge/sewage treatment, etc. Achieve lower operating costs, reduced maintenance, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

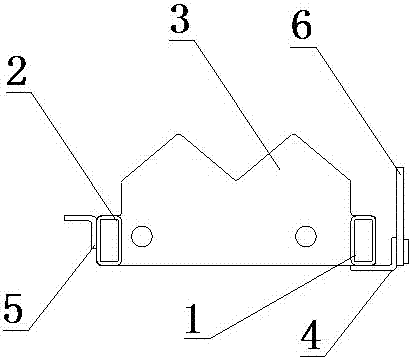

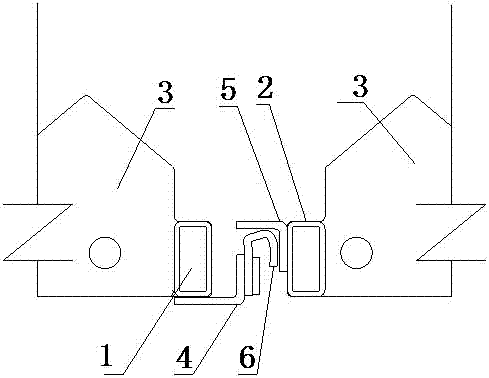

[0011] The present invention will be further explained below in conjunction with the accompanying drawings.

[0012] The invention discloses an internally rotating grill plate sealing connector, which comprises a group of grill plates, and the associated grill plates include a pair of upper support arms 1 and lower support arms 2 arranged horizontally and in parallel, one upper support arm and one lower support arm. The two ends of the support arm 2 are respectively connected by the fixing plate 3, a filter membrane plate is provided between the upper support arm 1 and the lower support arm 2, an upper seal coupling 4 is provided at the upper end of the upper support arm 1, and an upper seal coupling 4 is provided at the lower end of the lower support arm 3. The lower sealing coupling 5 ; the upper sealing coupling 4 and the lower sealing coupling 5 are alternately connected between adjacent grid plates, and a sealing strip 6 is provided between the upper sealing coupling 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com