a shaft structure

A shaft structure and pin shaft technology are applied in pivot connections, lighting devices, components of lighting devices, etc., which can solve problems such as increasing labor costs, friction noise, reducing product high-end quality, etc., and achieve the effect of adjusting the hand feeling experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

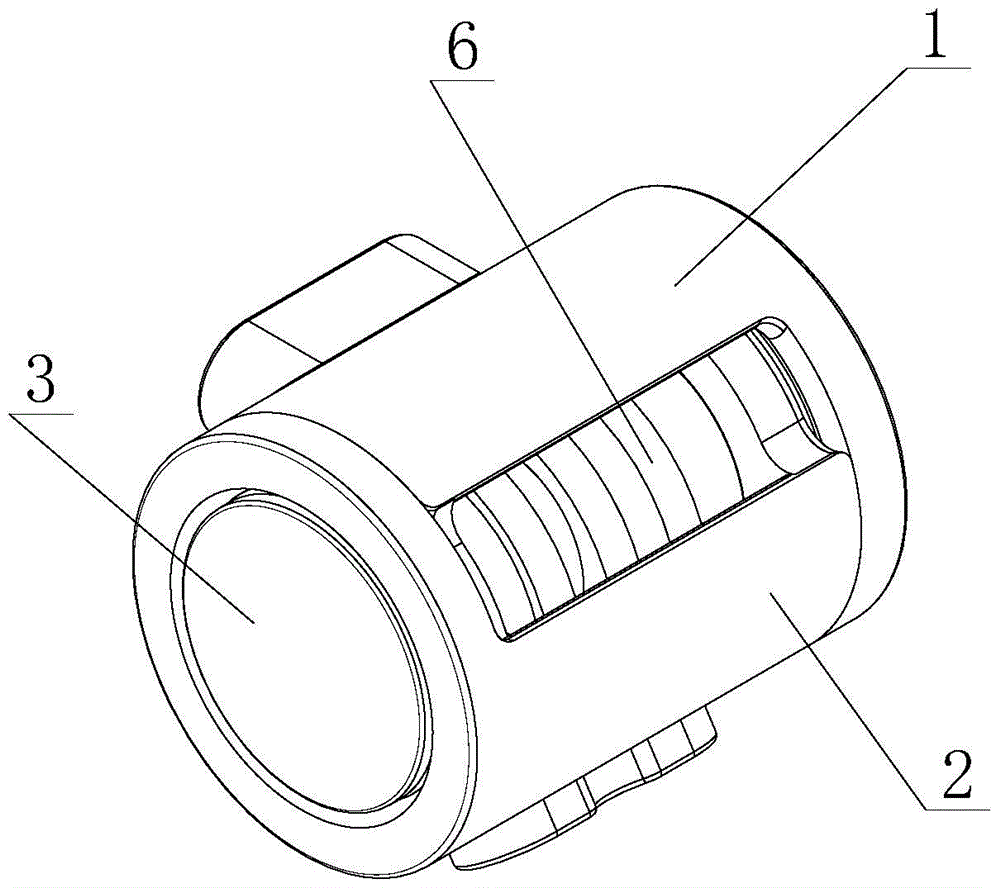

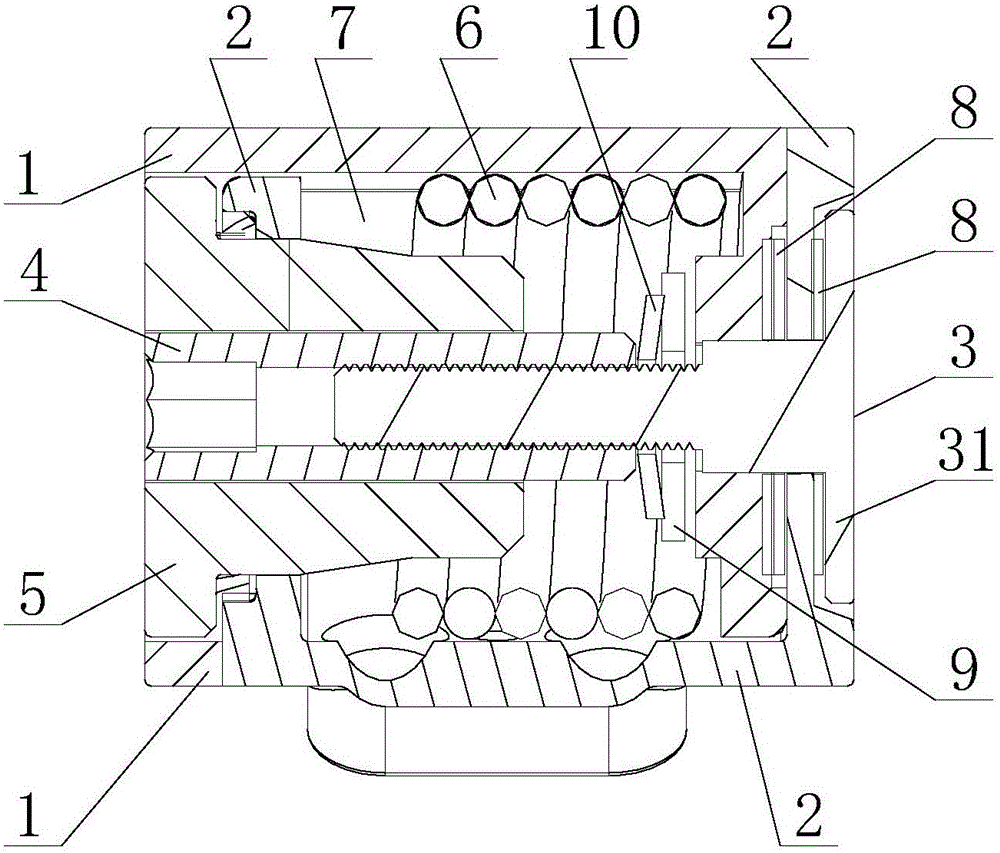

[0027] A shaft structure is provided in this embodiment, such as Figure 1-2 As shown, it includes an upper rod fixed shaft 1, a lower rod fixed shaft 2, a tightening screw 3 passing through the upper rod fixed shaft 1 and the lower rod fixed shaft 2 in turn, an internally threaded shaft 4 cooperating with the tightened screw 3 and locking pin 5;

[0028] At least one end of the upper rod fixed shaft 1 or the lower rod fixed shaft 2 is located in the lower rod fixed shaft 2 or the upper rod fixed shaft 1, and the upper rod fixed shaft 1 and the lower rod fixed shaft 2 can rotate with each other without axial displacement change , the end of the lower rod fixed shaft 2 away from the tightening screw 3 is also provided with a locking groove 21 that matches the locking pin 5; the upper rod fixed shaft 1 or the lower rod fixed shaft 2 is provided with a spring 6, and the lower rod is fixed A rotation groove 7 is provided on the side wall of the shaft 2; one end of the spring 6 is...

Embodiment 2

[0031] A shaft structure is provided in this embodiment, such as Figure 1-2 As shown, it includes an upper rod fixed shaft 1, a lower rod fixed shaft 2, a tightening screw 3 passing through the upper rod fixed shaft 1 and the lower rod fixed shaft 2 in turn, an internally threaded shaft 4 cooperating with the tightened screw 3 and Locking pin 5.

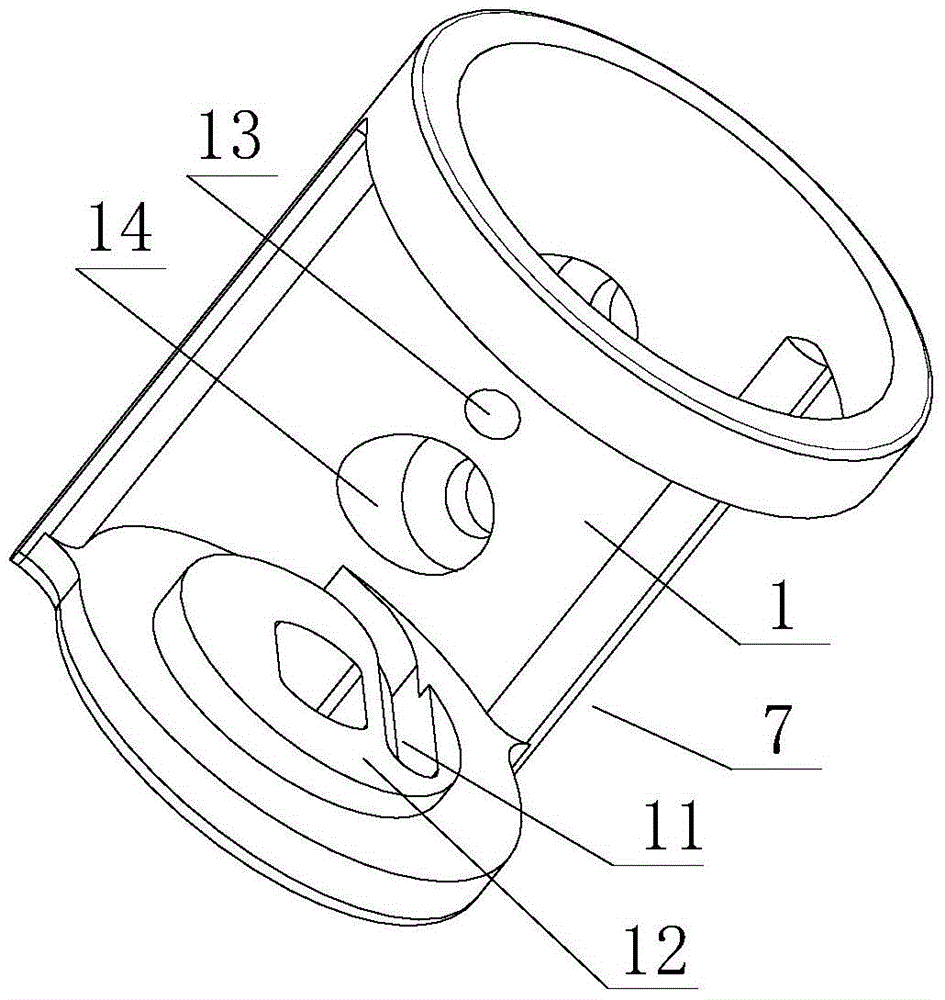

[0032] Such as Figure 3-4 As shown, the side walls of the upper rod fixed shaft 1 and the lower rod fixed shaft 2 are provided with a rotation groove 7, and one end of the upper rod fixed shaft 1 is located in the lower rod fixed shaft 2, and the upper rod fixed shaft 1 is fixed with the lower rod The shafts 2 are mutually rotatable and coaxial, and the other end of the upper rod fixed shaft 1 is located outside the lower rod fixed shaft 2; the same side of the upper rod fixed shaft 1 and the lower rod fixed shaft 2 are equipped with Tighten the through hole of the screw 3, and tighten the screw 3 through one end of the upper rod...

Embodiment 3

[0041] The difference with embodiment 2 in this embodiment is:

[0042] The upper rod fixed shaft 1 is located in the lower rod fixed shaft 2, and the upper rod fixed shaft 1 and the lower rod fixed shaft 2 are provided with a rotation groove 7, the spring 6 is located in the upper rod fixed shaft 1, and one end of the spring 6 is fixed to the upper rod The shaft 1 is fixed, and the other end is fixed with the locking pin 5.

[0043] Other structures are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com