Comprehensive appearance detection device for mechanical flow line production

Appearance inspection and assembly line technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of reducing the production efficiency and economic benefits of enterprises, low inspection efficiency, long maintenance cycle, etc., to enhance the production efficiency of enterprises And economic benefits, improve work efficiency, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

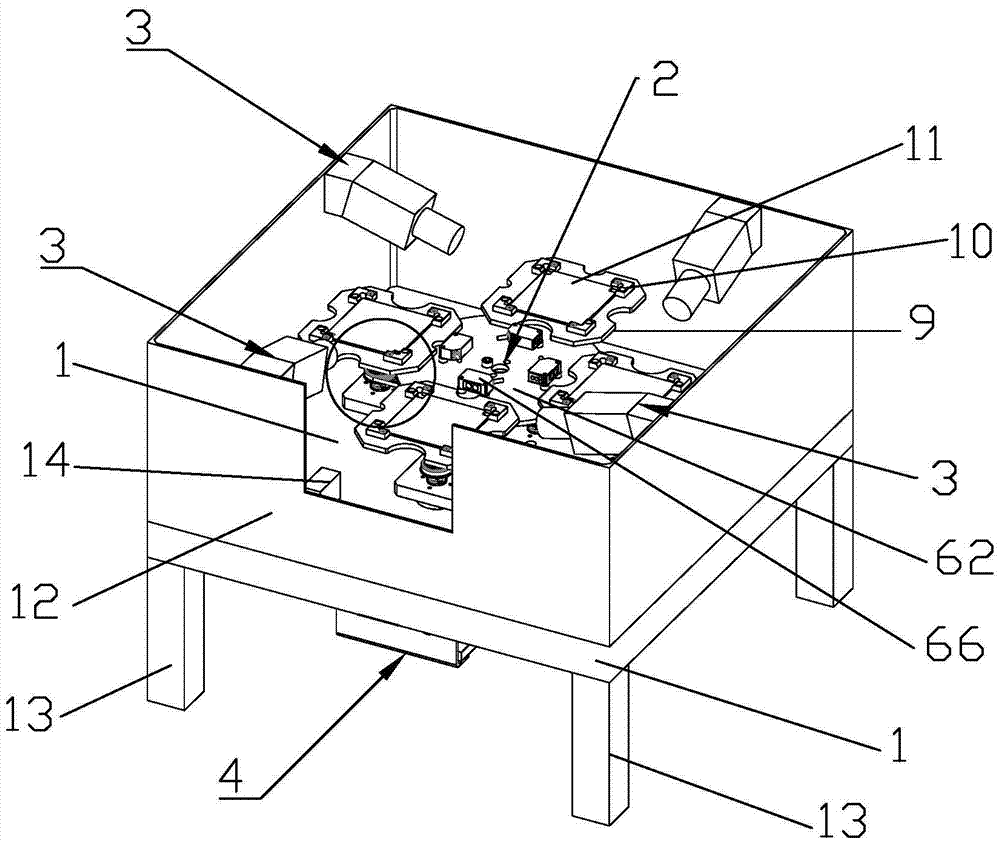

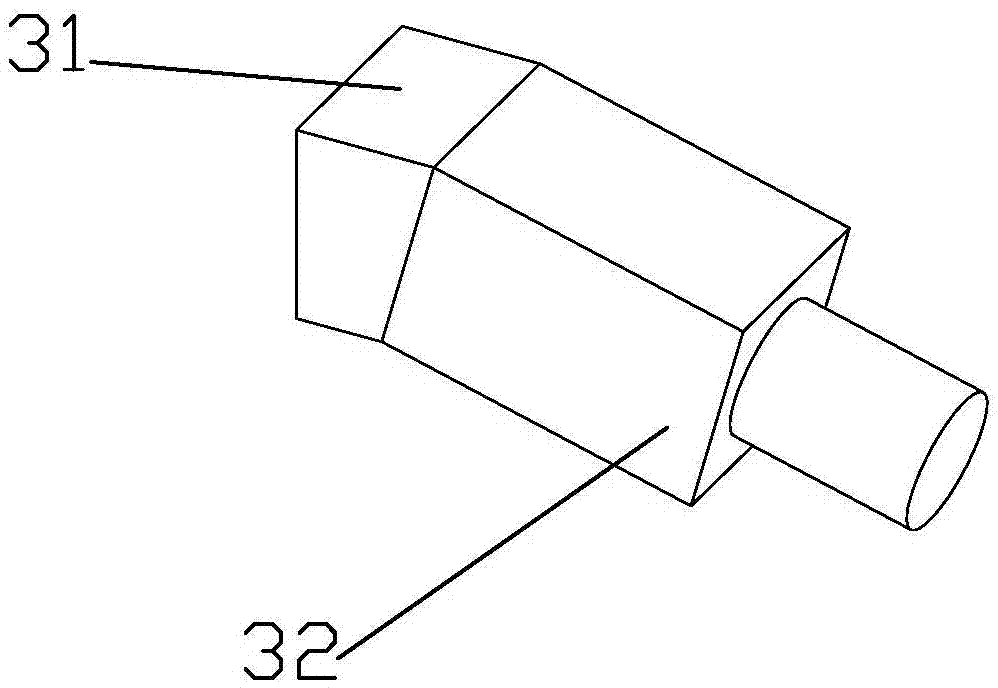

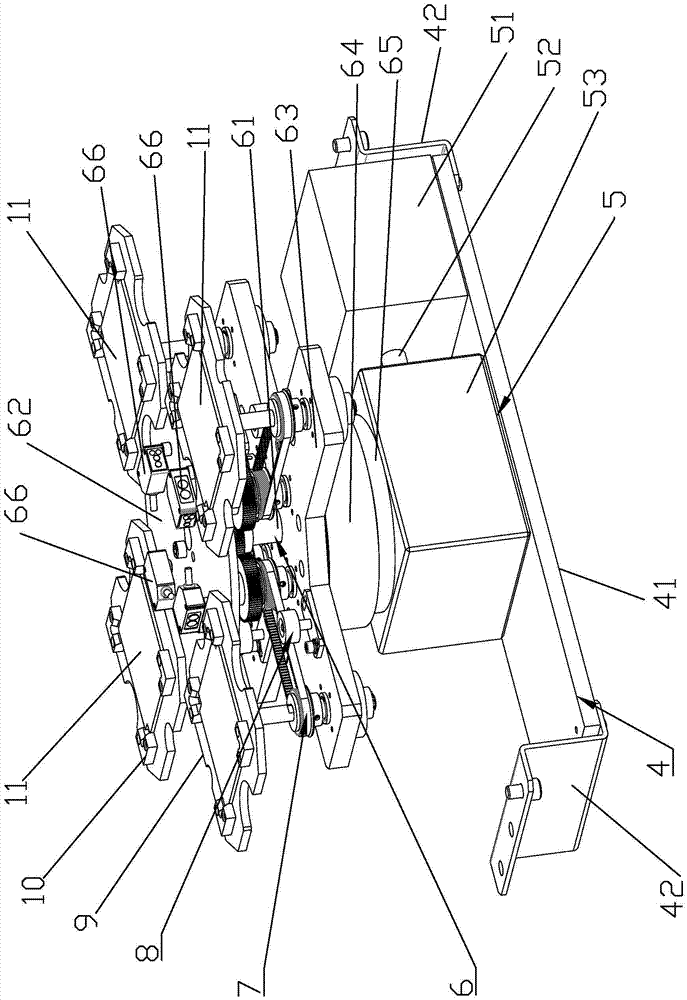

[0034] Such as Figure 1 to Figure 7 As shown, an all-round appearance inspection device for mechanical assembly line production includes an inspection base 1 and an inspection rotation mechanism 2 , and the inspection rotation mechanism 2 is installed on the center of the inspection base 1 . A detection mounting plate 12 is provided around the detection base 1, an appearance detection mechanism 3 is arranged on the detection mounting plate 12, a control box 14 is provided on the detection base 1, and the control box 14 is connected to the appearance detection mechanism 3, and the detection base 1 A detection fixing post 13 is provided at the lower end. The detection rotation mechanism 2 includes a rotation base assembly 4, a rotation drive assembly 5, a rotation transmission assembly 6 and a belt transmission assembly 7. The rotation base assembly 4 is fixedly installed on the detection base 1, and the rotation base assembly 4 is equipped with a rotation drive assembly. Asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com