Automatic deviation correction method and system for optical axis of machine core of camera

An automatic deviation correction and camera technology, applied in image communication, television, electrical components, etc., can solve problems such as error-prone, time-consuming, and inaccurate mathematical functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

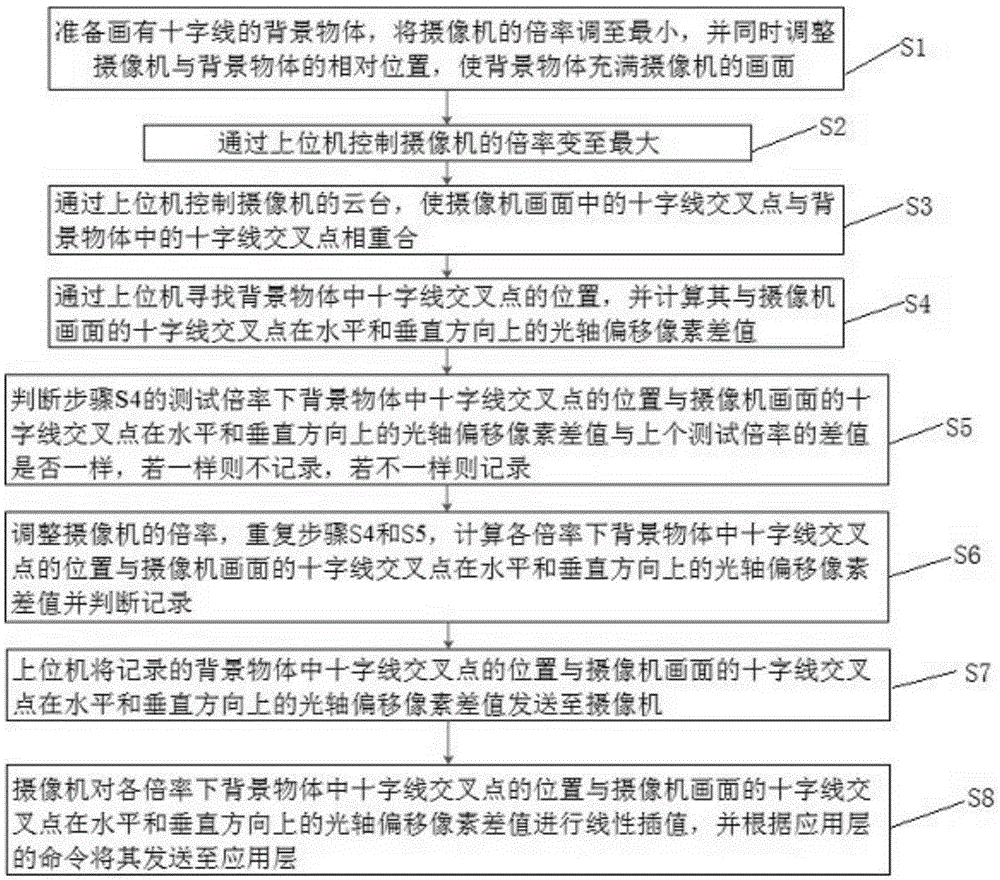

[0051] Example: such as figure 1 As shown, a method for automatically correcting the optical axis of a camera movement includes:

[0052] S1. Prepare the background object with crosshairs, adjust the magnification of the camera to the minimum, and adjust the relative position between the camera and the background object at the same time, so that the background object fills the image of the camera;

[0053] S2. Change the magnification of the camera to the maximum through the host computer;

[0054] S3. Control the pan / tilt of the camera through the host computer, so that the intersection point of the crosshairs in the camera picture coincides with the intersection point of the crosshairs in the background object;

[0055] S4. Find the position of the intersection point of the crosshairs in the background object through the host computer, and calculate the optical axis offset pixel difference between the intersection point of the crosshairs and the camera screen in the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com