Power plant steam and water system comprehensive corrosion monitoring system and method

A soda-water system, comprehensive corrosion technology, applied in measuring devices, machine/structural component testing, instruments, etc., can solve problems such as non-sharing of water chemical treatment information, unreasonable corrosion monitoring locations, and lack of unified management of equipment. The effect of evaluating the completeness of the analysis system and improving the amount of information exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

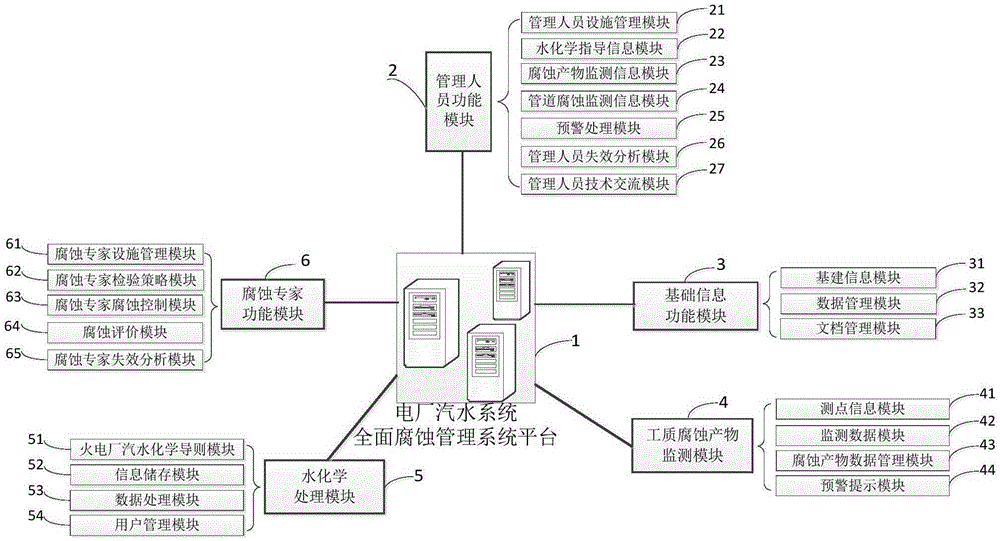

[0033] The present invention provides a comprehensive corrosion monitoring system and method for a steam-water system in a power station. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

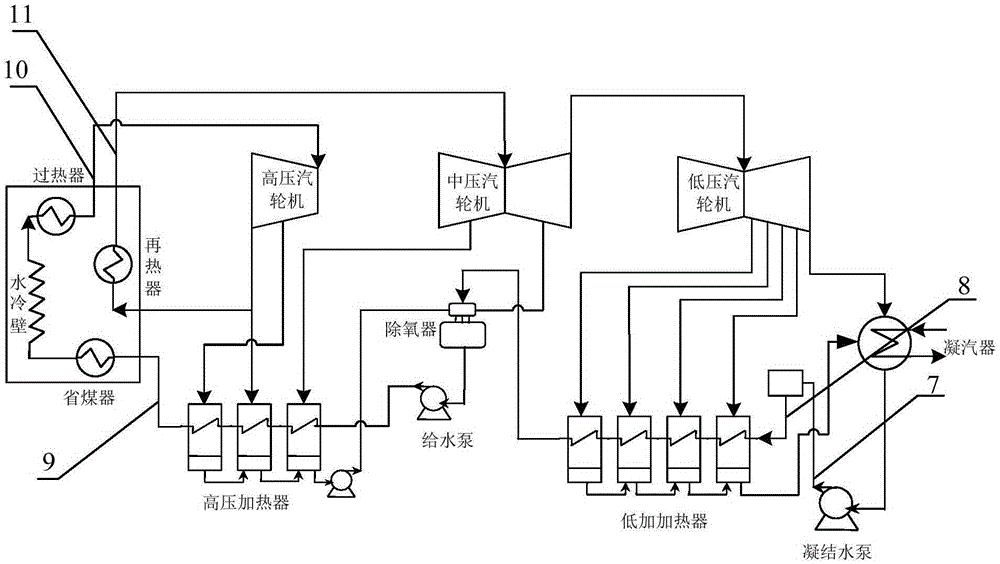

[0034] figure 1 It is a schematic diagram of the position of the corrosion product monitoring point of the comprehensive corrosion monitoring system of the steam-water system of the power station according to the present invention; the specific meanings of each label in the figure are: 7-the outlet of the condensate water pump; 8-the outlet of the condensate polishing treatment; 9-the economizer Inlet; 10-superheater outlet; 11-reheater outlet.

[0035] Set conductivity meter, acidity meter, sodium meter, silicon meter and dissolved oxygen meter at outlet 7 of condensate water pump; install conductivity meter, acidity meter, sodium meter, silicon meter and dissolved oxygen meter at outlet 8 of condensate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com