Inclined plate desulfurization synergistic device suitable for wet desulfurization

A wet desulfurization and synergist technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of large flue gas resistance, excessive liquid holding capacity, and high operating costs, and achieves simple system structure. Wide operating flexibility and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A carbon factory calciner flue gas treatment device

[0026] The flue gas parameters are as follows:

[0027] name

1 # ,2 # Furnace flue gas (two furnaces and one tower)

Equipped with boiler

Calciner

Flue gas flow (Nm 3 / h)

14150 (1 # Furnace)+14150(2 # furnace)

temperature °C

180~200

Import SO 2 Concentration (mg / Nm 3 )

6600

Imported soot concentration (mg / Nm 3 )

30

SO 2 Emission concentration (mg / Nm 3 )

≤100

Emission soot content (mg / Nm 3 )

≤10

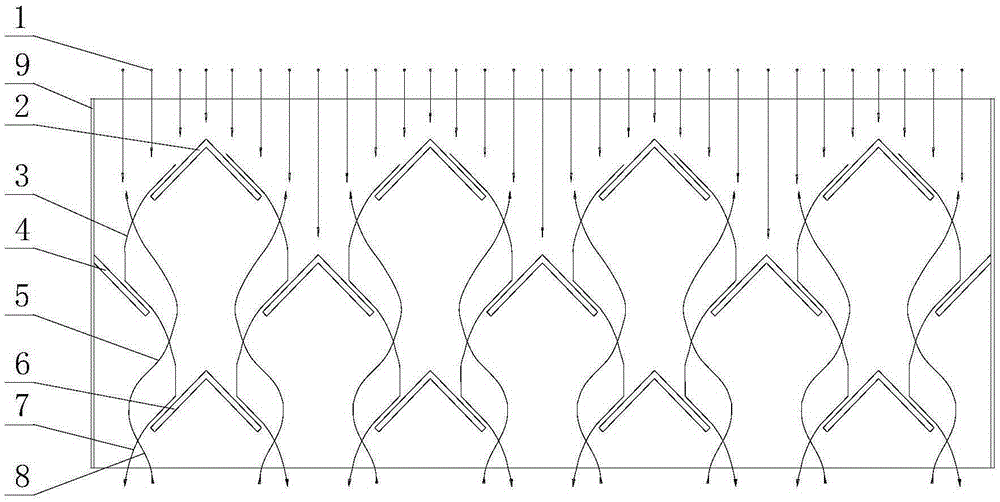

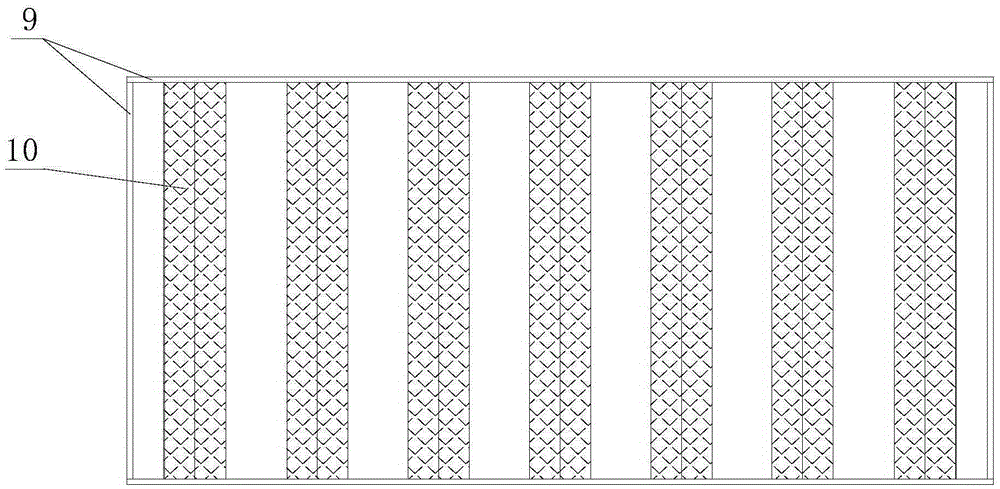

[0028] The desulfurization unit adopts the limestone-gypsum wet desulfurization process, and the process flow of the desulfurization area is shown in Figure 4 ,1 # ,2 # After the furnace flue gas is combined, it enters the middle of the desulfurization tower, first passes through two layers of desulfurization boosters, then passes through four layers of spray layers, and finally is discharged from the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Board width | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com