Annular numerical control electric welding machine

An electric welding machine and ring-shaped technology, which is applied in the field of numerically controlled ring-shaped electric welding machines, can solve problems such as welding difficulties, uneven weld seams, and uncontrollable weld seam sizes, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

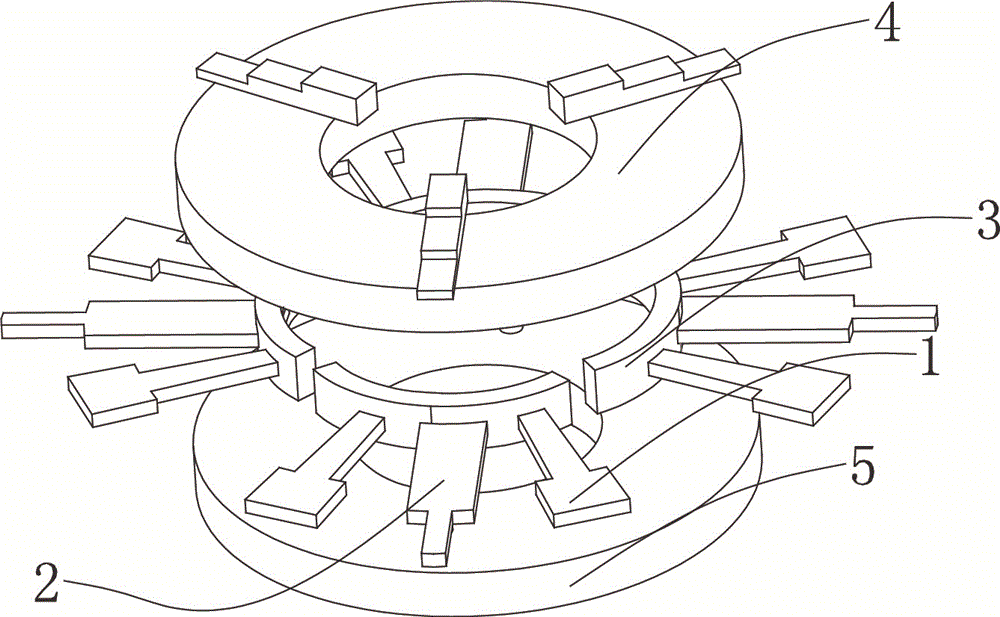

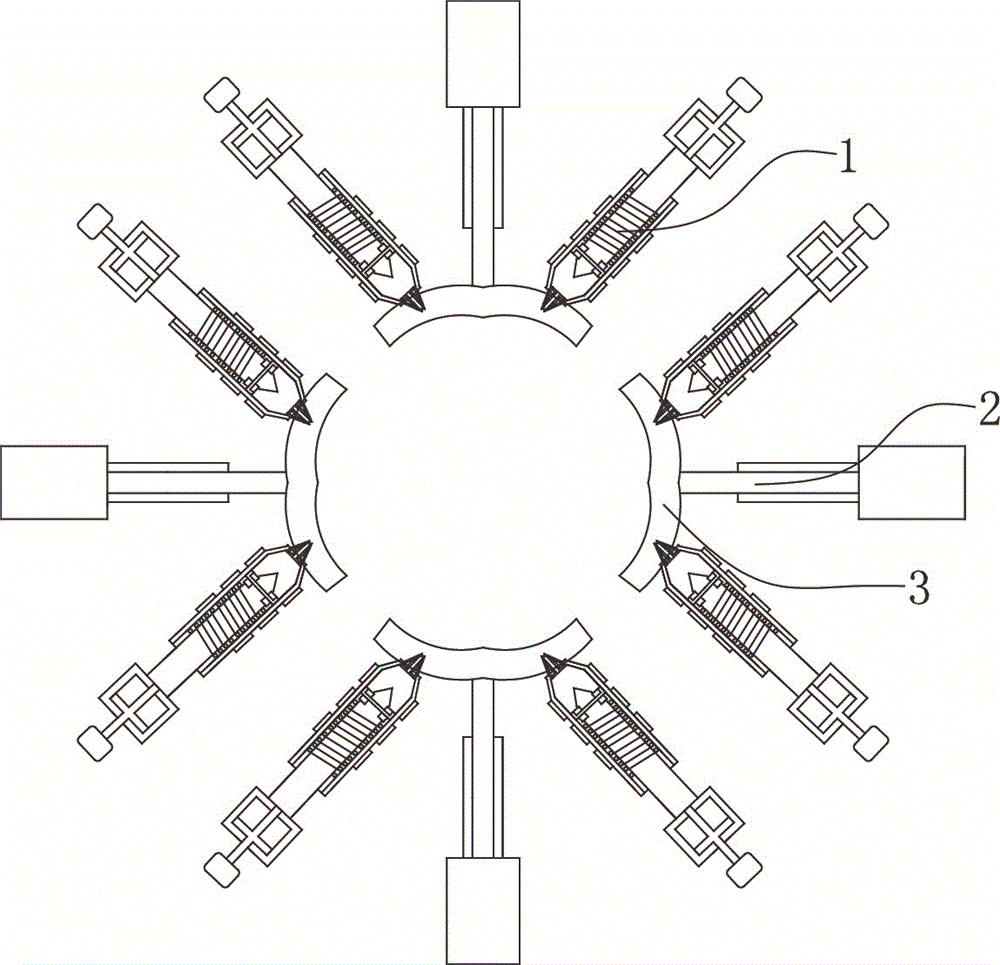

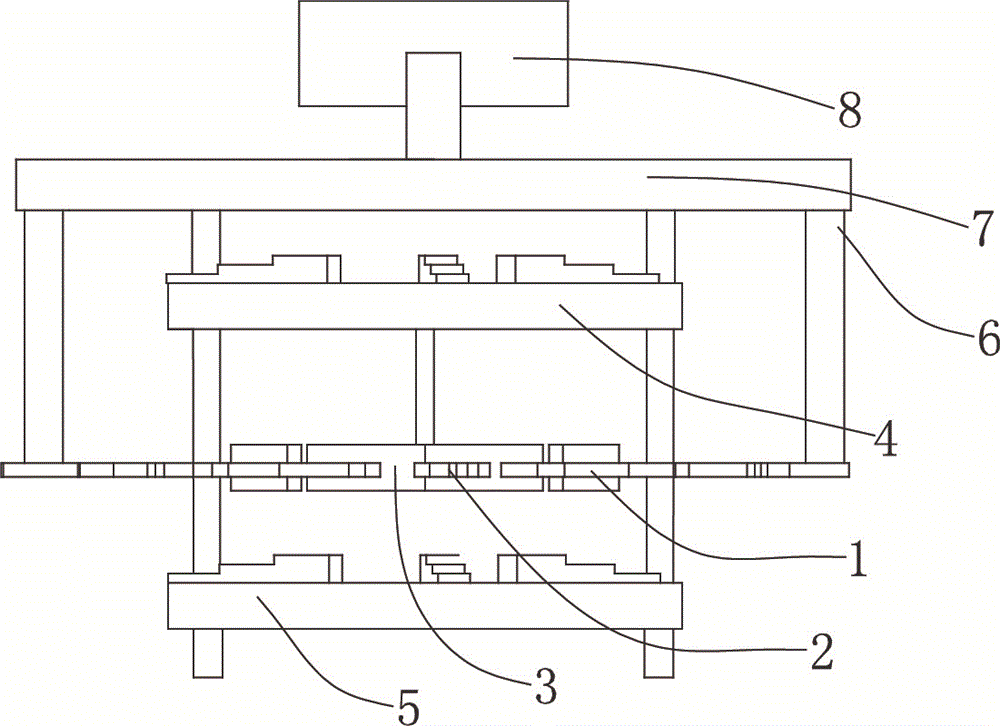

[0021] A numerically controlled annular electric welding machine, comprising a plurality of arc-shaped welding blocks 3, the arc-shaped welding blocks 3 form a ring, and an output port 31 is opened on the arc-shaped welding block 3, and the described output port is A plurality of neatly arranged hollow holes, the arc welding block 3 is a hollow shell, the shell is divided into two layers, the inner material is tungsten, the outer material is aluminum, the arc Shape welding block 3 comprises left arc-shaped block and right arc-shaped block that are connected as a whole, and the angle of described left arc-shaped block and right arc-shaped block is between 50 degree and 60 degree, and described arc-shaped welding block 3 There is a sliding mechanism connected in the middle, the left arc-shaped block and the right arc-shaped block are provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com