Flying shear control method

A flying shear control and speed technology, applied in the field of flying shear control, can solve the problems that it is difficult to find the fault point and eliminate the fault, and the maintenance personnel cannot understand the control principle, etc., and achieve the effect of improving the cutting precision and high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

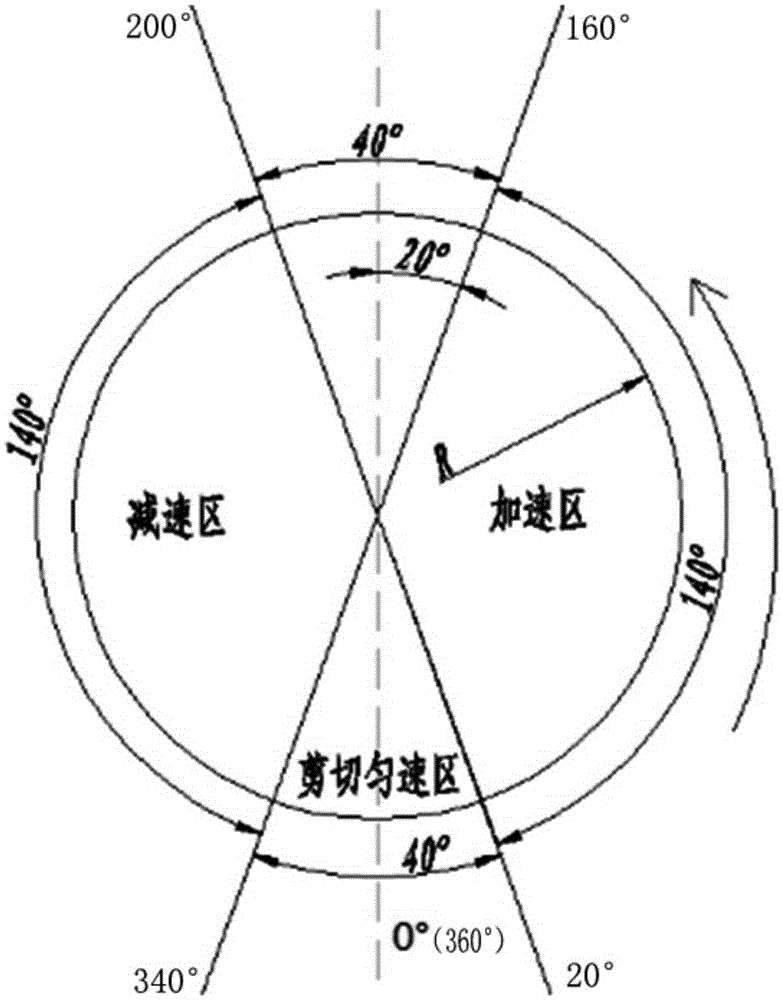

[0030] See figure 1 , the method of flying shear control, the total speed of rolling during continuous shearing satisfies: V=V b +V C (1);

[0031] In formula (1): V is the total speed of the drum; V b is the shear point velocity; V c is the additional velocity;

[0032] V b =V m (1+V m %)(2);

[0033] In formula (2): V m is the strip speed, V m % is the percentage of cutting blade advance speed;

[0034] V m The value of % is 4.8%-5.2%;

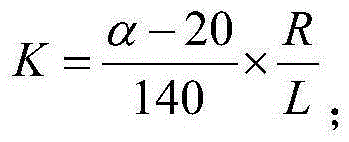

[0035] V c =V m ×K(3)

[0036] In formula (3): K is the additional speed coefficient;

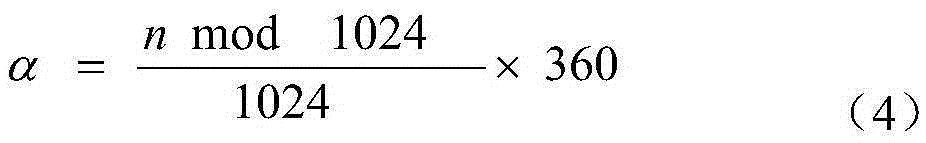

[0037] The cutting edge angle α (0° to 360° cycle) is the code number actually collected by the encoder divided by 1024 to take the remainder, then divided by 1024 and multiplied by 360, which satisfies form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com