Casting Method of Steam Turbine Valve Housing Castings

A technology for steam turbines and valve casings, which is applied to casting molding equipment, casting molds, and casting mold components, and can solve problems such as easy cutting of castings, difficulty in setting up hidden risers, and difficulty in ensuring the size of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

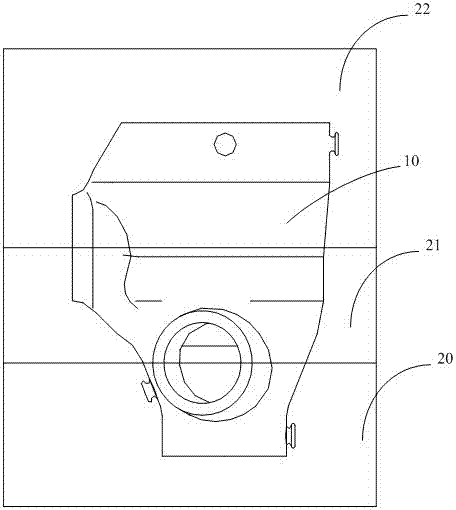

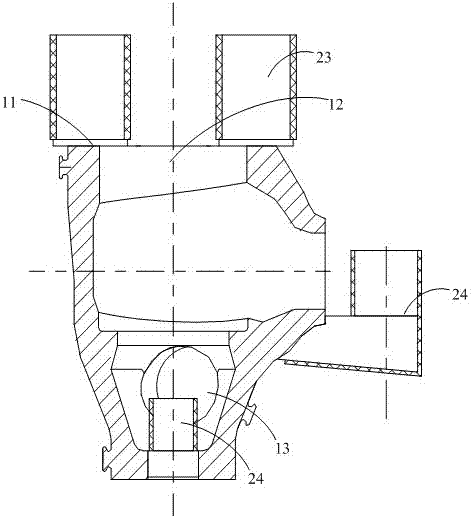

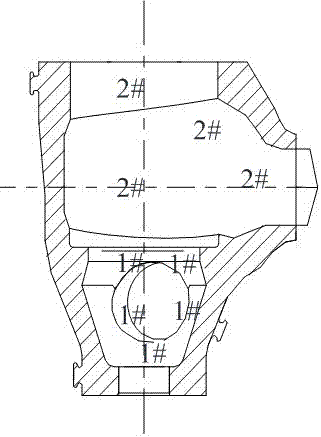

[0019] The invention provides a casting method of steam turbine valve housing castings, please refer to Figure 4 to Figure 7 , including the following steps:

[0020] Step S300, separate manufacturing of the solid model of the steam turbine valve casing casting: select the largest section of the steam turbine valve casing casting as the parting surface, and make the corresponding upper valve casing casting solid model split 31 and the lower valve casing casting solid model split 32. After the split 31 of the solid model of the upper valve casing is matched with the split 32 of the solid model of the lower valve casing, a solid model of the solid model of the steam turbine valve casing corresponding to the casting of the steam turbine valve casing is formed, and the middle nozzle 33 is located on the upper valve casing On the split body 31 of the casting solid model, the middle nozzle 33 is parallel to the parting surface.

[0021] Step S301, modeling: lower box molding, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap