High-efficiency intelligent vibrating screen

A vibrating screen and high-efficiency technology, applied in the field of vibrating screen, can solve the problem of difficult replacement of the screen body, and achieve the effect of shortening the replacement time, simple results and increasing the working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

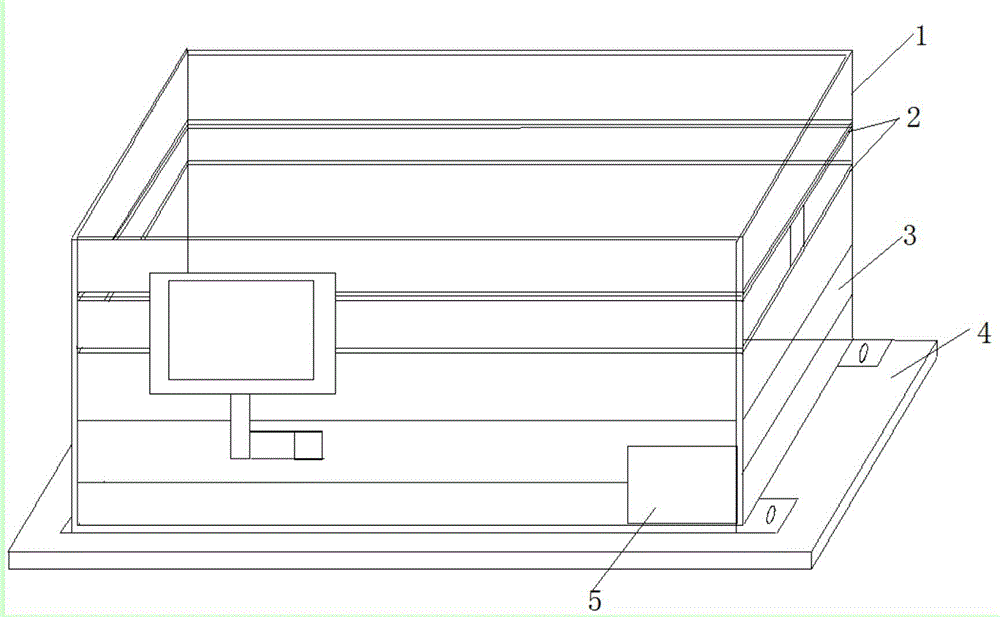

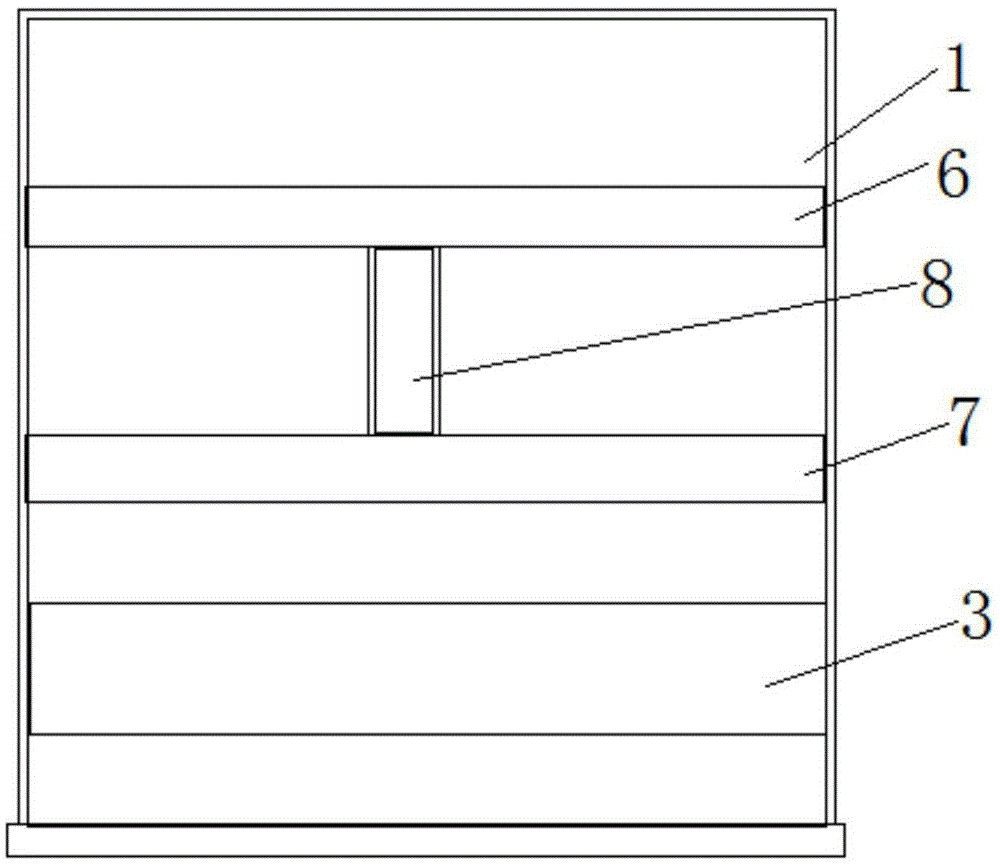

[0032] Such as figure 1 , figure 2 with image 3 The shown high-efficiency intelligent vibrating screen includes: a frame 1, a receiving box 3, a vibrating plate 4, at least two sieve bodies 2, an intelligent control device 5 and a driving device for sieve body replacement.

[0033] The relationship between the above components is as follows:

[0034] The receiving box 3 is arranged on the bottom of the frame 1, and the vibrating plate 4 is arranged on the horizontal direction of the frame 1, and it is characterized in that: it also includes: the sieve body 2 is arranged on the Above, the intelligent control device 5 is arranged on the frame 1 , and the associated driving device is connected with the screen body 2 and the intelligent control device 5 .

[0035] The frame 1 described in this embodiment is located above the receiving box 3 and is provided with an inlet and outlet of the sieve body 2, and the inlet and outlet are divided into an upper inlet and outlet 6 and a...

Embodiment 2

[0039] The vibrating screen in this embodiment has the same structure as the vibrating screen in Embodiment 1.

[0040] A working method of a high-efficiency intelligent vibrating screen described in this embodiment, the specific working method of the high-efficiency intelligent vibrating screen is as follows:

[0041] (1): First, the staff opens the vibrating screen, and adjusts the maximum vibration frequency of the vibrating screen by operating the intelligent control device according to the needs of production. After the parameters are adjusted, click the "Start" button to let it enter the working state;

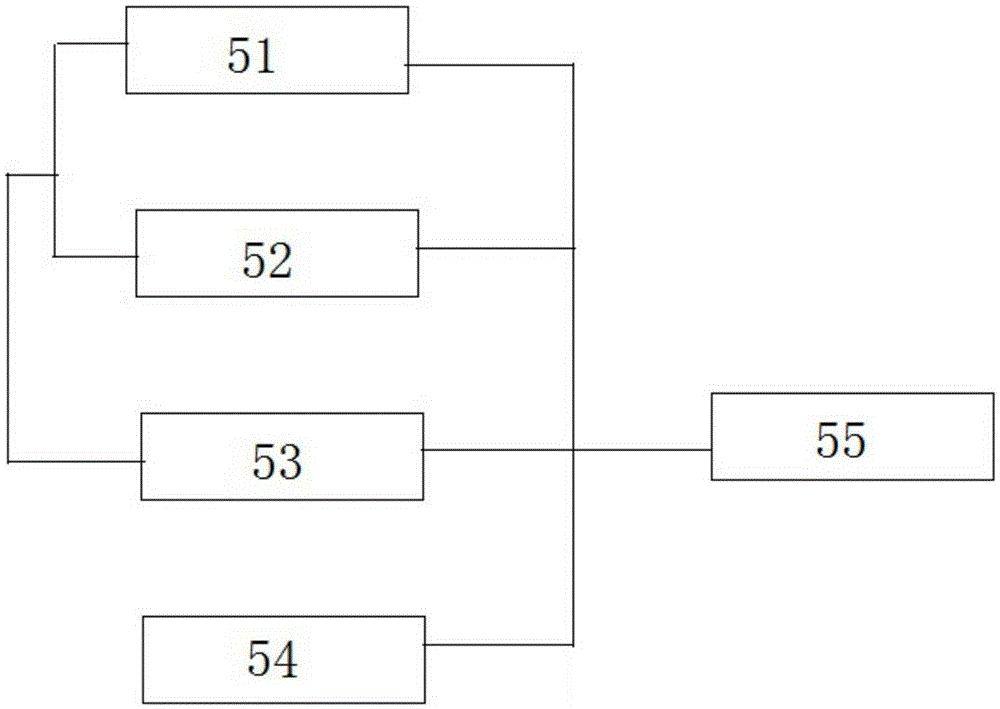

[0042] (2): Then use the controller module 55 in the intelligent control device 5 to order the vibrating plate 4 to start vibrating;

[0043] (3): After the vibrating plate 4 works normally, start pouring sand into the sieve body 2 continuously to screen the sand;

[0044] (4): After working for a period of time, the operator presses the "Sieve Body Replacement" button,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com