Paper-making net supporting device and method for dismantling the paper-making net

A technology for paper making nets and supporting nets, which is applied in the directions of transportation and packaging, winding strips, and thin material handling. Net and plug quality, fast and convenient transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

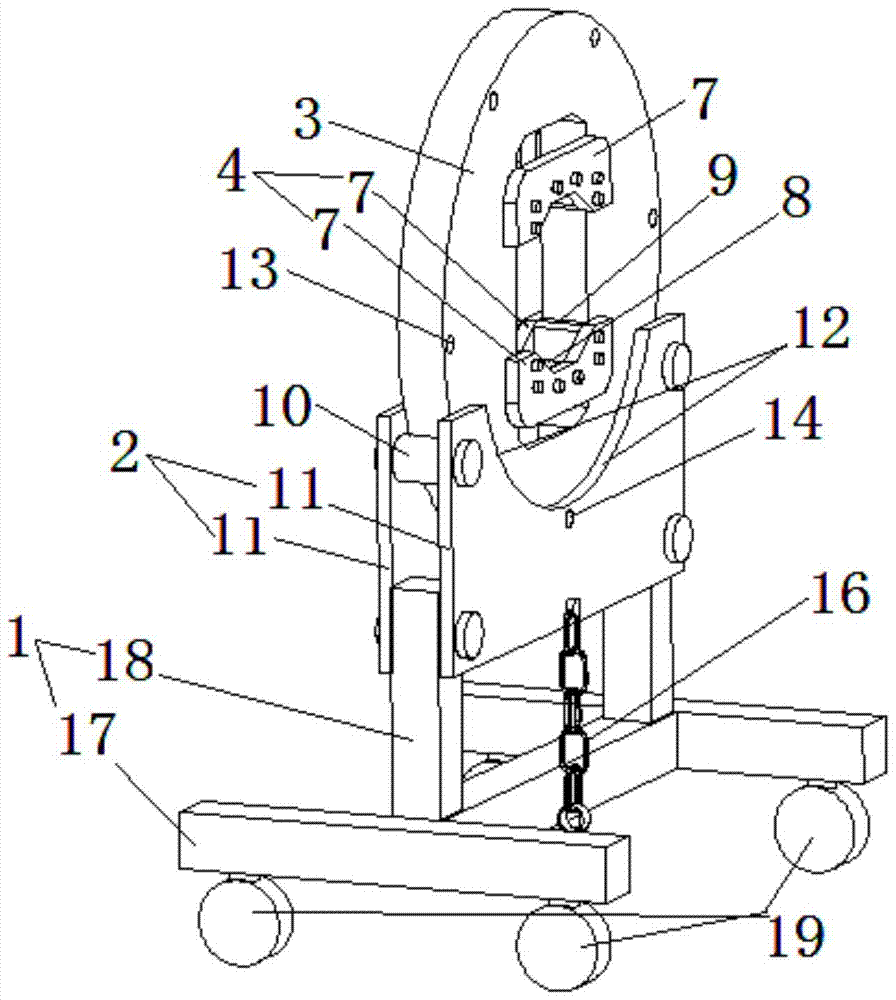

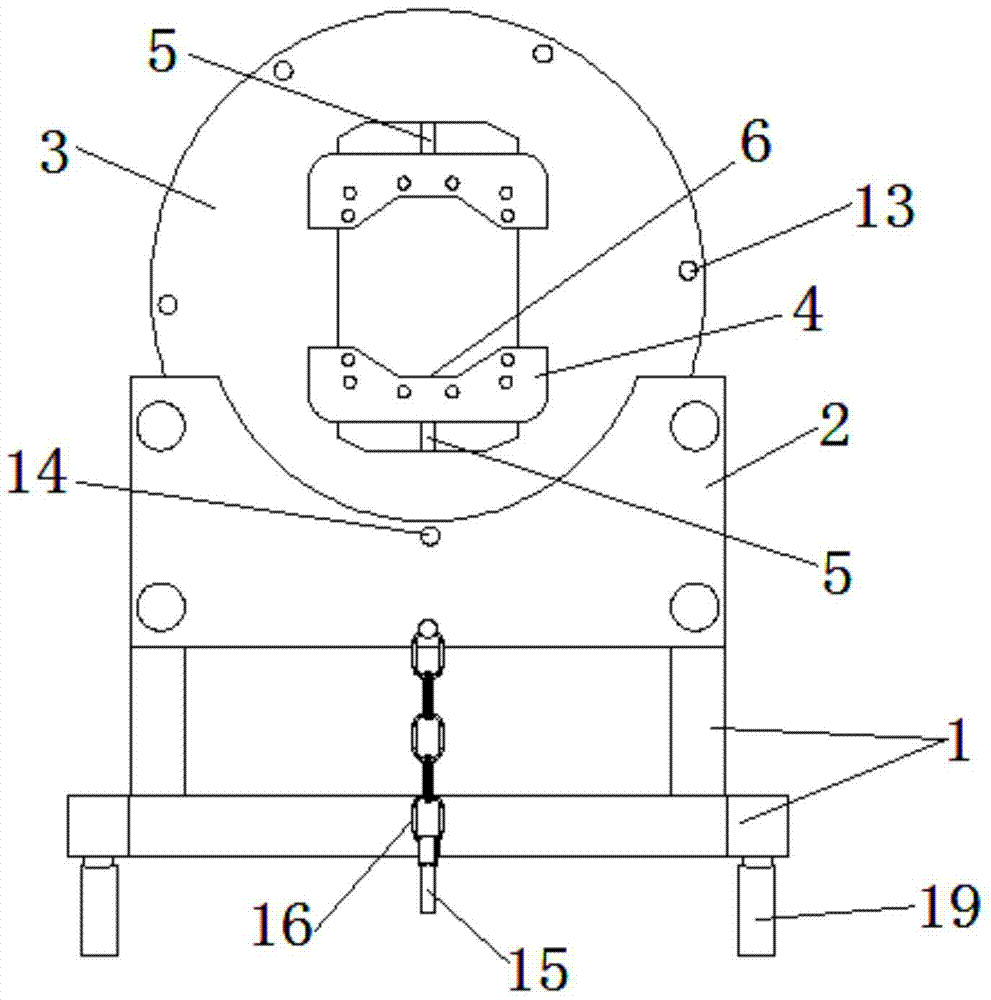

[0024] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0025] Such as figure 1 and figure 2 As shown, the paper-making net support device, the paper-making net is wound on the reel, and includes a support net mechanism supported on both ends of the reel. The support net mechanism includes a base 1 with universal rollers 19, and the base 1 is provided with a support Seat 2, the support seat 2 is provided with a support wheel 3 that can rotate on the support seat 2, and the support wheel 3 is provided with a clamping mechanism for clamping the reel. After wrapping the cardboard on the reel, put it into the clamping mechanism and clamp it through the clamping mechanism, turn the supporting wheel 3, and slowly pull out the paper-making net along the drawn end of the paper-making net, so that the paper-making net can be removed, which is not only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com