A kind of popping beads, beverage containing same and preparation method thereof

A technology of popping beads and beverages, which is applied in the direction of sugary food ingredients, bacteria used in food preparation, food coating, etc. It can solve the problem of single variety, inability to wrap base materials containing probiotics, and inability to form film-in-water And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

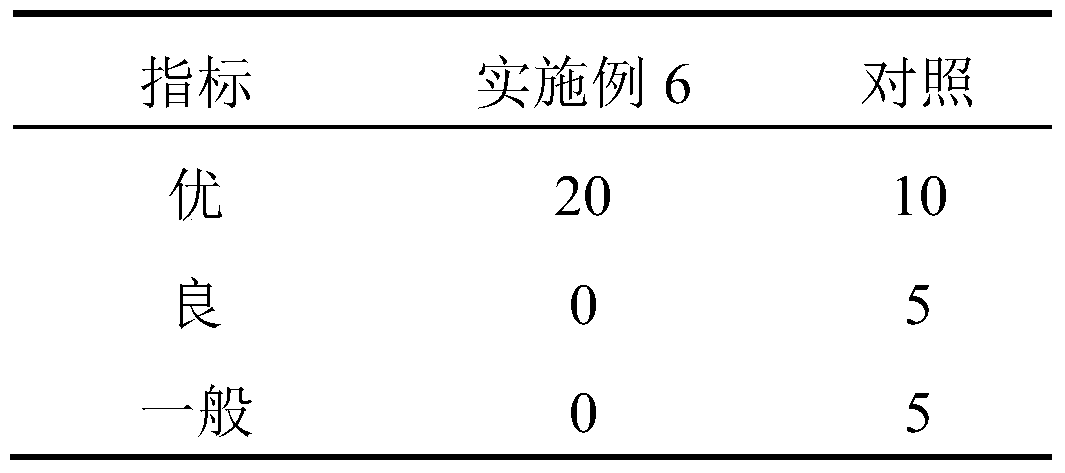

Examples

Embodiment 1

[0048] Embodiment 1 The preparation of the quick-fried pearl containing active probiotic

[0049] (1) Preparing reconstituted milk: blend skim milk powder and water at a mass ratio of 1:7 to prepare reconstituted milk; wherein, the mass percentage of protein in the skim milk powder is 34%;

[0050] (2) Preparation of active probiotic base material: preheat the obtained reconstituted milk to 60°C, homogenize at 25MPa; sterilize at 95°C for 120min; cool to 32°C, inoculate 1×10 6 cfu / mL, fermented at 32°C for 72 hours to obtain active probiotic base material;

[0051] (3) Preparation of sugar water protection solution containing sodium alginate: Stir 10% white granulated sugar, 0.05% sodium alginate, 2% trehalose, 5% glycerin and 100% water at 70°C for 15 minutes until mixed Evenly, sterilize at 95°C for 5 minutes, and cool to 42°C to obtain the probiotic sugar water protection solution; percentages are mass percentages;

[0052] (4) Preparation of active probiotic popping bead...

Embodiment 2

[0054] Embodiment 2 The preparation of the quick-fried pearl containing active probiotics

[0055] (1) Preparation of active probiotic base material: preheat fresh skim milk with a protein content of 3.4% to 65°C, homogenize at 20MPa; sterilize at 90°C for 30min; cool to 30°C, inoculate cheese milk Bacillus 1×10 6 cfu / mL and Streptococcus thermophilus 1×10 6 cfu / mL, 42 ℃ incubation and fermentation for 8 hours to obtain active probiotic base material;

[0056] (2) Prepare a sugar water protection solution containing sodium alginate: mix 12% glucose syrup, 0.5% sodium alginate, 1% trehalose, 0.02% Tween-80, 0.02% sodium glutamate and supplement Stir the water to 100% at 70°C for 15 minutes until it is evenly mixed, sterilize at 95°C for 5 minutes, and cool to 28°C to obtain the probiotic sugar water protection solution; percentages are mass percentages;

[0057] (3) Preparation of popping beads containing active probiotics: Mix active probiotic base material and probiotic su...

Embodiment 3

[0059] Embodiment 3 The preparation of the quick-fried pearl containing active probiotic

[0060] (1) Preparation of active probiotic base material: preheat fresh milk with a protein mass percentage content of 3.0% and a fat mass percentage content of 3.1% to 62°C, homogenize at 17MPa; sterilize at 90°C for 90min; cool At 30°C, inoculate Lactobacillus acidophilus 1×10 6 cfu / mL, fermented at 28°C for 64 hours to obtain active probiotic base material;

[0061] (2) Prepare a sugar water protection solution containing sodium alginate: mix 0.06% of aspartame, 2% of sodium alginate, 1.5% of trehalose, 1% of glycerin, 0.2% of vitamin C, 0.02% of Temperature-80, 0.02% mannitol, 0.02% sodium glutamate and 100% water were stirred at 45°C for 15 minutes until evenly mixed, sterilized at 95°C for 5 minutes, and cooled to 42°C to obtain probiotics Bacteria sugar water protection liquid; Percentage is mass percent;

[0062] (3) Preparation of popping beads containing active probiotics: m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com