Belt core formation device for conveying belts

A forming device and conveyor belt technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of low production efficiency, poor production continuity, easy peeling, etc., to reduce labor intensity and improve production efficiency , Good lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

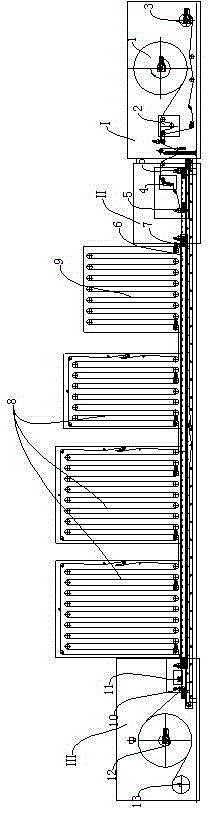

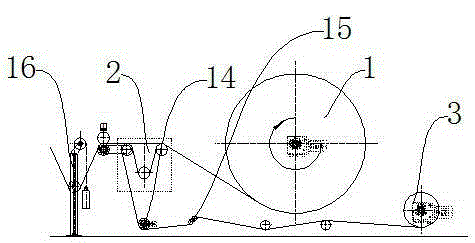

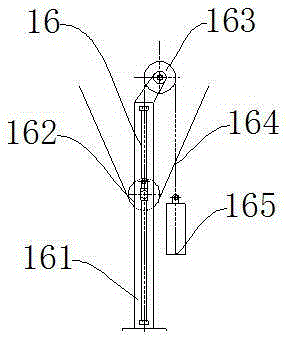

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the conveyor belt core forming device described in this embodiment includes a roll guide device 1, an interlining finishing device 2 and an interlining winding device 3, and also includes an upper conveyor belt 6 and a lower conveyor belt 7, and the lower conveyor belt 7 is located below the upper conveyor belt 6, and there is a gap between the two; a No. 1 cutting device 4 is set at the entrance of the upper conveyor belt 6, and three sets of bonding The pressure roller group 5 is provided with three height frame devices 8 and a height adjustment frame device 9 at intervals above the upper conveyor belt 6; A No. 2 cutting device 11 is arranged between the groups 10, and a core take-up device 12 and a lining cloth guiding device 13 are arranged on the outside of the end of the upper conveyor belt 6; A row of horizontal guide roller sets 17 are respectively arranged on the top and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com