Assembly method for external hanging lenses

A lens assembly, lens technology, applied in glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as heavy weight, damage to the aesthetics of glasses, and increased weight of glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The main purpose of the present invention is to provide a method for assembling an add-on lens that can select the type of lens to be used according to the function required by the consumer, and can match the shape of the frame of the glasses used.

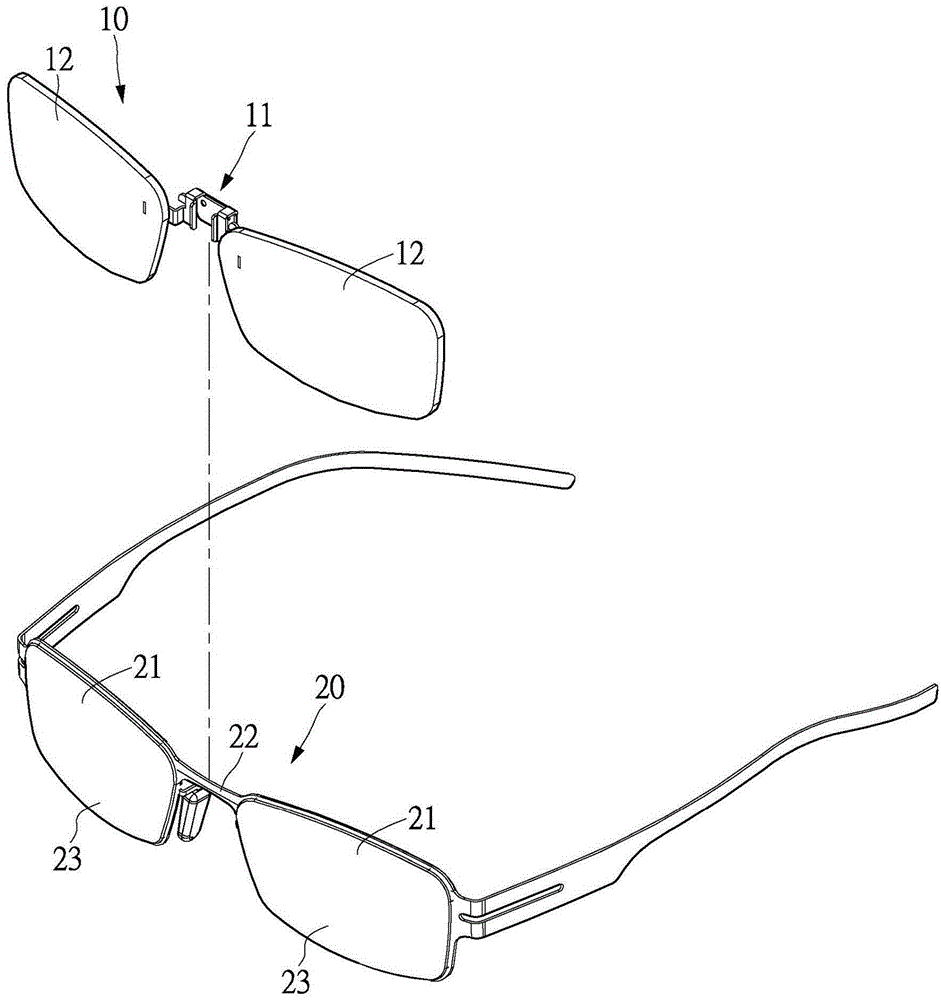

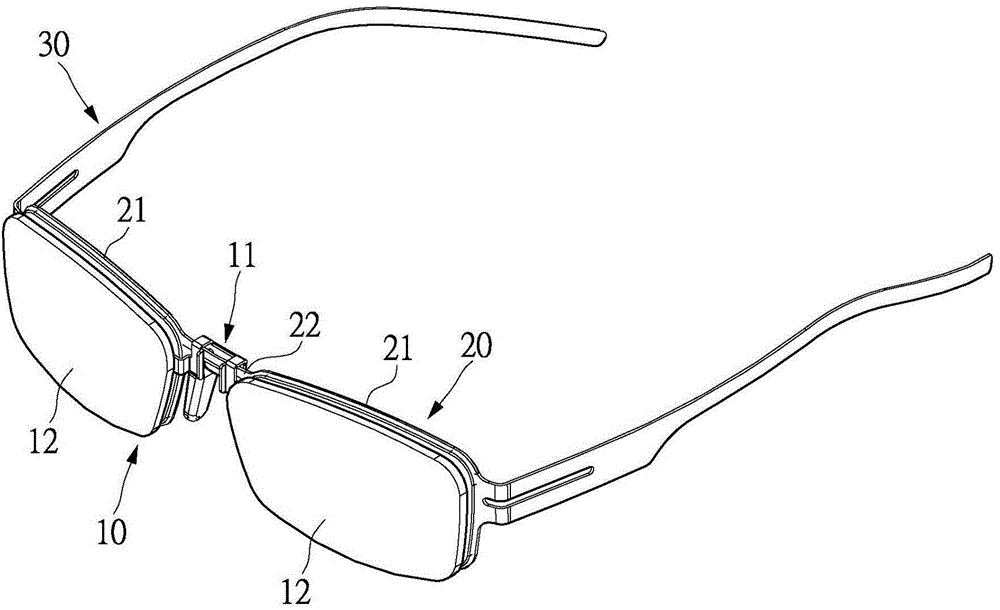

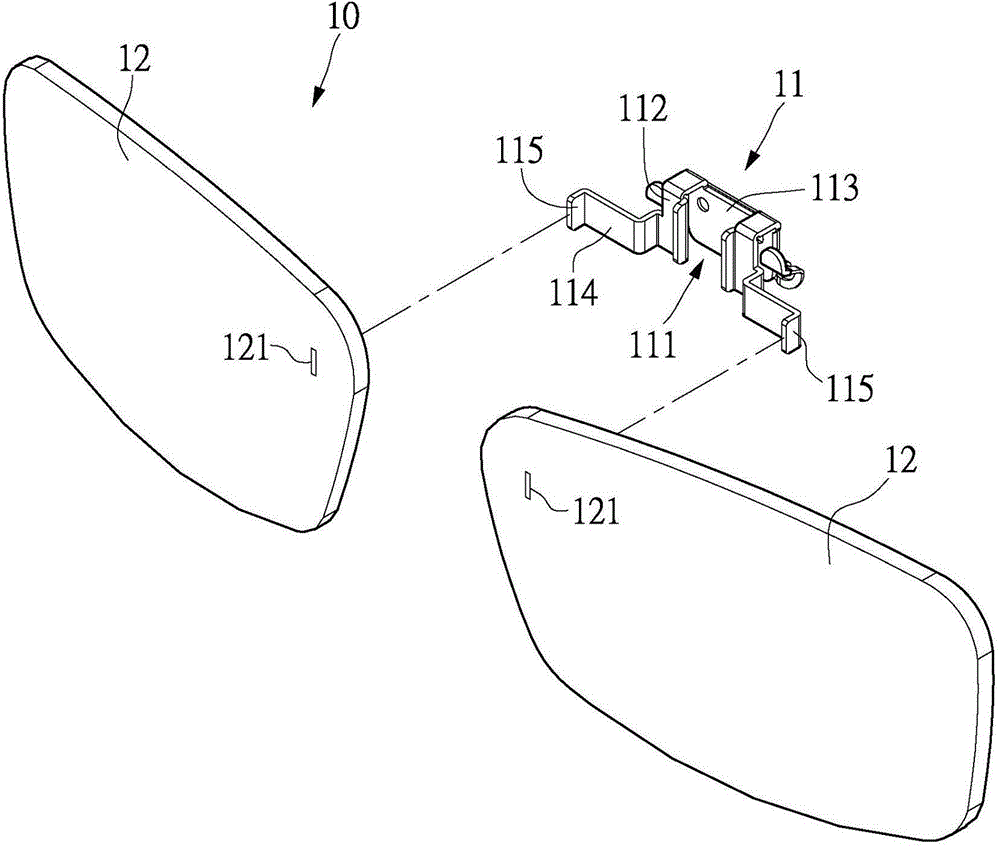

[0068] Such as figure 1Shown is a structure of an external lens 10 assembled by the method of the present invention and a pair of glasses 20 used in conjunction with the external lens 10 . In this embodiment, the glasses 20 are thin frame glasses, which have two lens frames 21 , two main lenses 23 disposed in the lens frames 21 , and a bridge 22 connected between the two lens frames 21 . The external lens 10 includes two additional lenses 12 and a suspension component 11 connected between the two additional lenses 12 .

[0069] The feature of this external lens 10 is that the suspension component 11 it adopts is made of metal material, and the same material and color as the frame material of the glasses 20 can be selected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com