Eddy current detection device for automobile galvanized sheet plating thickness and method

A technology of coating thickness and detection device, applied in electromagnetic measurement device, electric/magnetic thickness measurement, etc., can solve the problems of harmfulness to human body and expensive equipment, and achieve the effect of easy online detection, fast detection speed and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

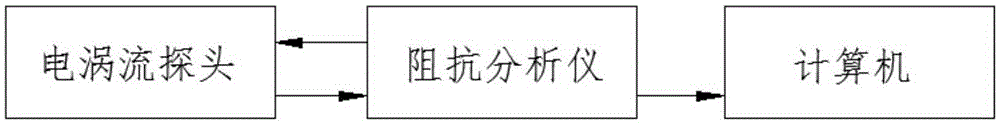

[0047] Such as figure 1 Shown, the present invention is a kind of eddy current detecting device of the coating thickness of galvanized sheet for automobile, and it comprises:

[0048] An eddy current probe, an impedance analyzer, a fixture for fixing the test piece 3-2, and a computer;

[0049] The eddy current probe is placed on the surface of the test piece 3-2 in the fixture, and is connected to the impedance analyzer, and the output end of the impedance analyzer is connected to the computer;

[0050]Wherein, the impedance analyzer generates a sinusoidal excitation signal to drive the eddy current probe to generate an excitation magnetic field and act on the tested object 3-2, and the eddy current probe senses and outputs a signal which is processed by the impedance analyzer and then input to a computer for analysis.

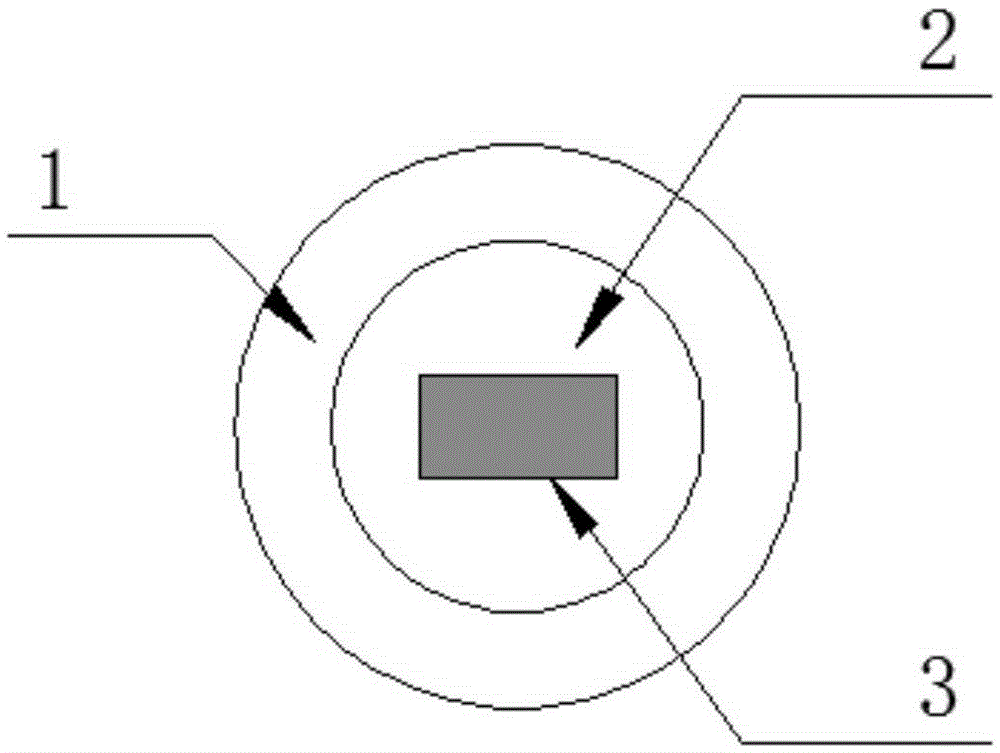

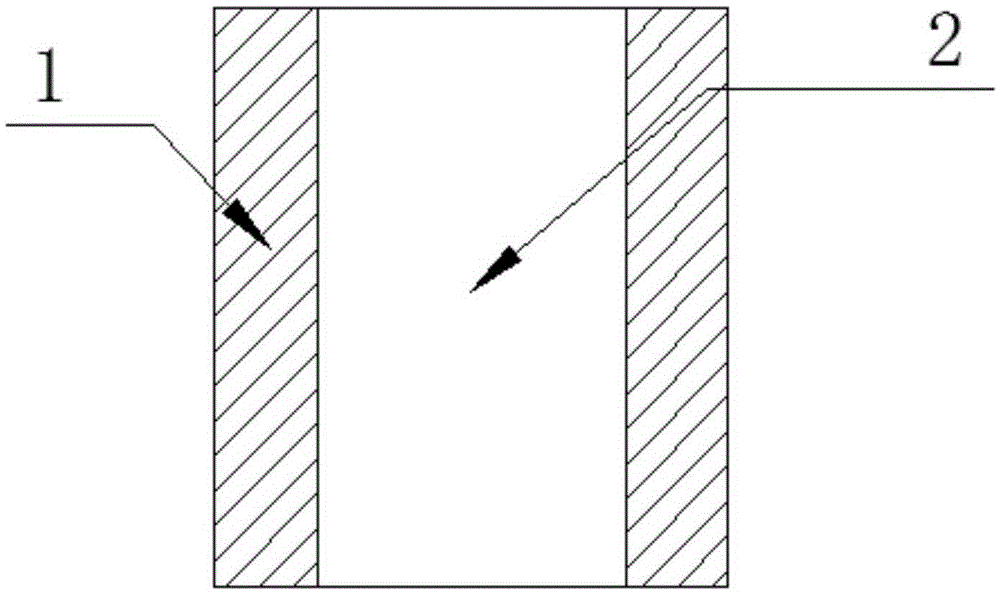

[0051] Such as figure 2 , image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com