Electronic component storage box

An electronic component and storage room technology, applied in the field of storage boxes, can solve the problems of low efficiency, restricted production capacity, artificial wasteful consumption, etc., and achieves the effects of large storage quantity, simple structure and high storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

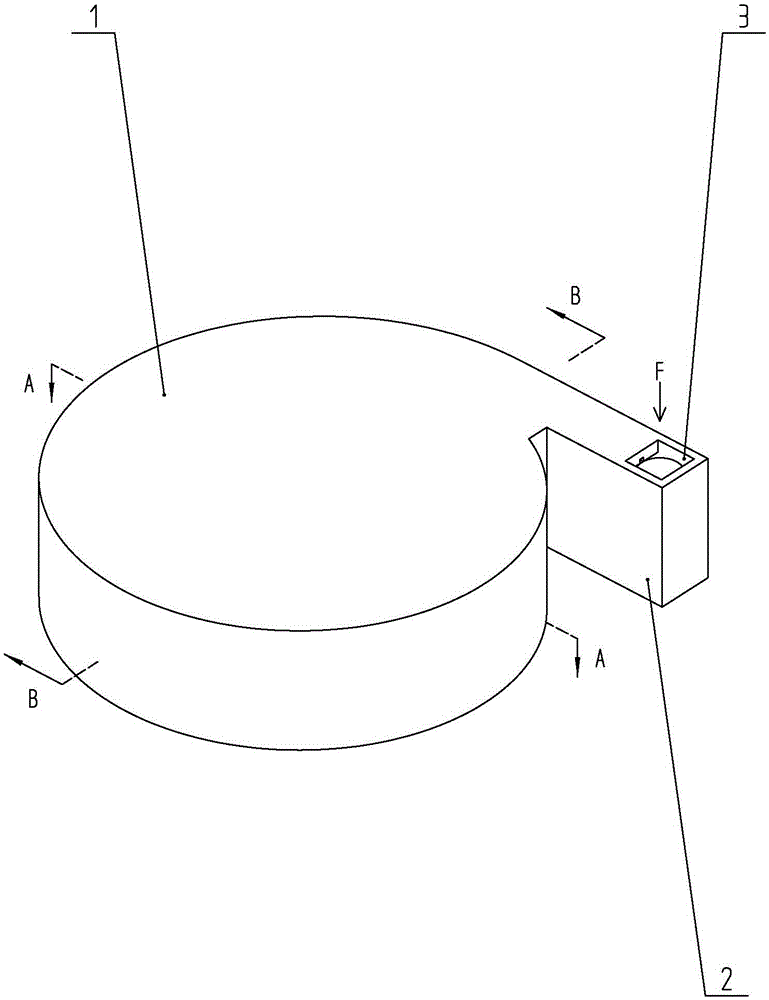

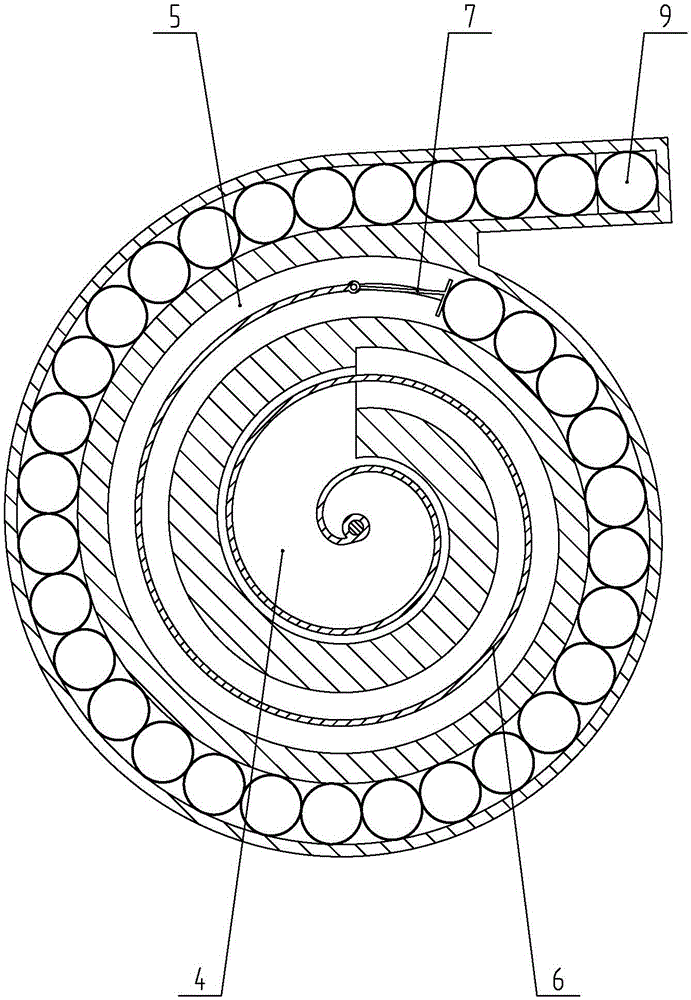

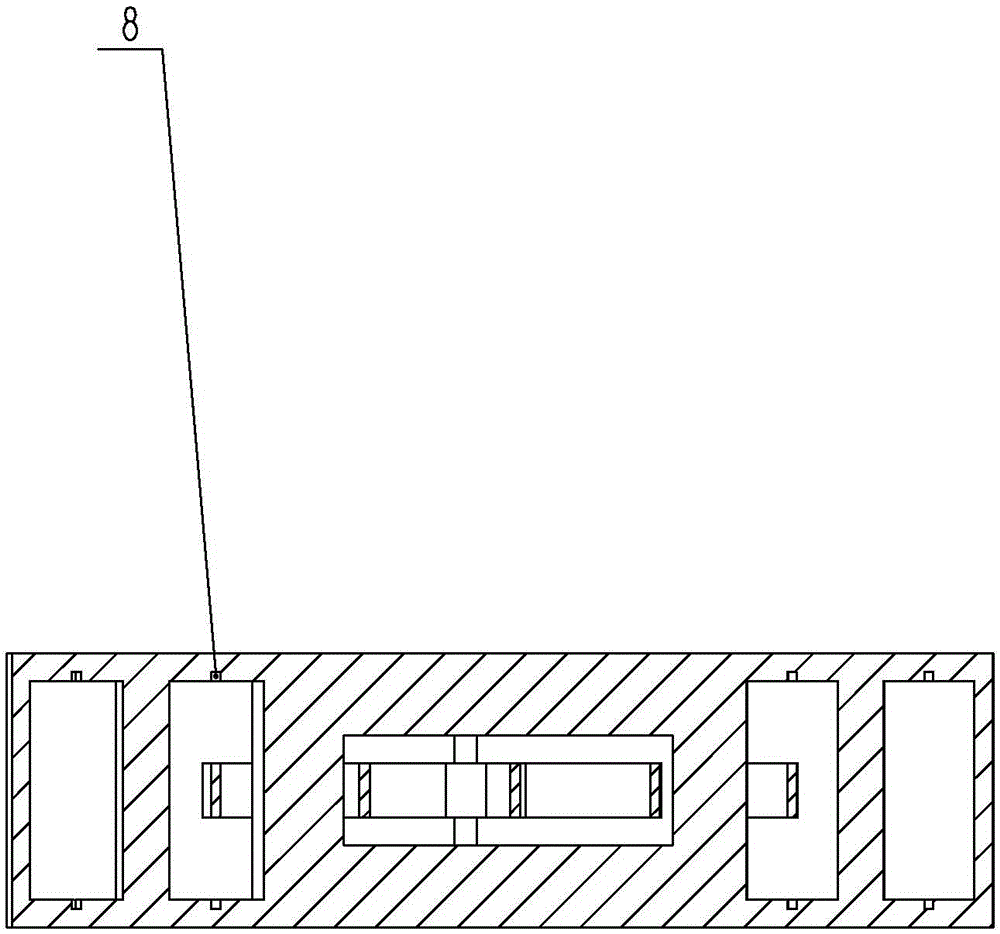

[0017] like Figures 1 to 3 As shown, an electronic component storage box includes a casing 1 formed by injection molding of hard plastic and having a cavity. a convex portion 2 . A front end of the convex part 2 is provided with a cover body (not shown), and the cover body is detachably mounted on the front end of the convex part 2 by bolts. The cavity includes a first storage chamber 4 located in the middle of the housing 1 and a second storage chamber 5 surrounding the first storage chamber 4 and having a spiral structure. The inner end of the second storage chamber 5 communicates with the first storage chamber 4, and its outer end extends into the convex portion 2; the convex portion 2 is provided with a through hole 3 through the side wall, and the outer end of the second storage chamber 5 passes through the through hole 3 communicate with the outside. A clockwork spring 6 is arranged in the cavity, and a movable block 7 is arranged in the second storage chamber 5 ; T...

Embodiment 2

[0019] The difference from Embodiment 1 is that in this embodiment, the cover body is hinged with the convex shell through a pin shaft, and the movable end of the cover body can be locked or released from the convex part 2 through a locking mechanism, so that the cover body can be wound around The pin rotates to close or open the front end of the protrusion 2 .

[0020] When storing the workpieces 9 , the cover at the front end of the convex portion 2 is opened, and the workpieces 9 enter the second storage chamber 5 side by side one by one. As the number of workpieces 9 increases, the movable block 7 gradually squeezes the clockwork spring 6 to make it shrink and has greater potential energy. When the second accommodating chamber has been filled with workpieces 9, it is only necessary to close the cover.

[0021] When taking the piece, a force F aligned with the through hole 3 is applied through the thimble (such as cylinder drive), and the workpiece 9 (the first workpiece) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com