Automatic production equipment for detonator bayonet

A technology of production equipment and bayonet, which is applied in the direction of detonators and offensive equipment, etc., can solve the problems of direct contact with detonators, no reliable bayonet machine, and no human-machine isolation, so as to avoid low efficiency and avoid introduction Length inaccuracy, effect of improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

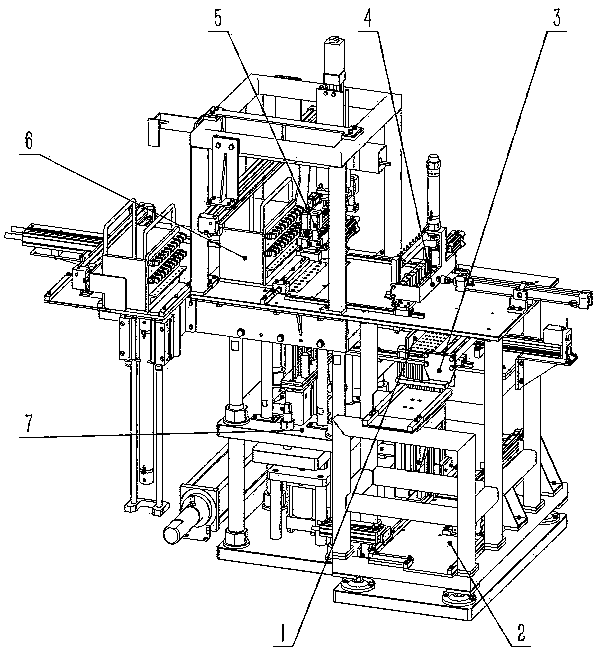

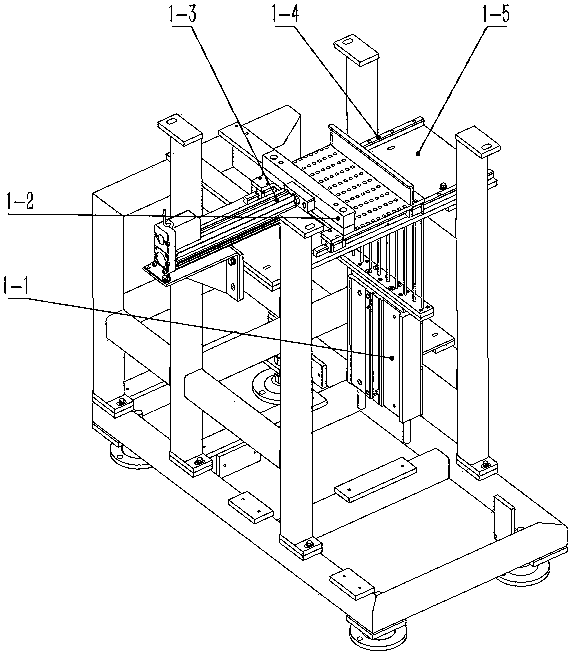

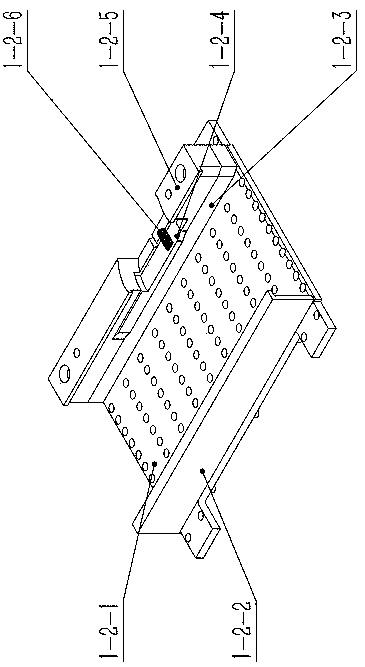

[0051] see figure 1 As shown, the detonator bayonet automatic production equipment of the present invention includes a pipe jacking device 1 for detonator ejection, a mold ejection device 2 for mold transfer, a mold feeding device 3 for mold transfer, and a feeding device for detonator transfer. Tube device 4, a mechanical finger device 5 for taking and sending guide tubes and finished detonators, a bayonet box device 6 for transporting detonators and detonators, a bayonet device 7 for detonator bayonets, and the ejector The device 1 is arranged below the pipe delivery device 4, and the positions correspond to each other; the mold ejection device 2, the pipe jacking device 1 and the mold entry device 3 are fixed on the same frame; the pipe delivery device 4 and the bayonet device 7 are positioned Corresponding; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com