An automated rehabilitation therapy nursing bed driven by a linear motor

A linear motor and rehabilitation therapy technology, which is applied in vehicle ambulance, hospital beds, medical transportation, etc., can solve the problems of difficult automatic control of patients, not fast enough displacement, and low precision, and achieves easy control, rapid and stable changes, and realization of The effect of precise displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

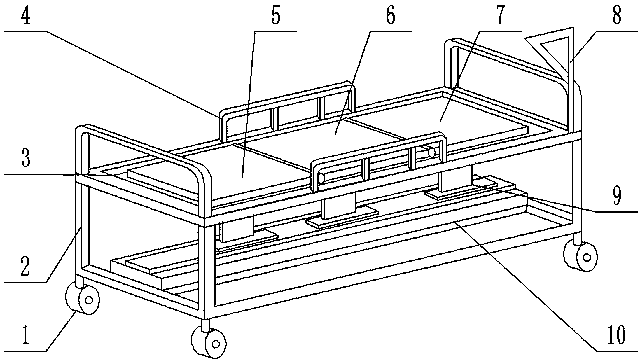

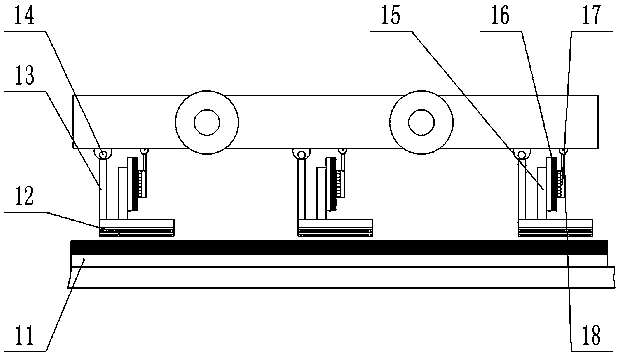

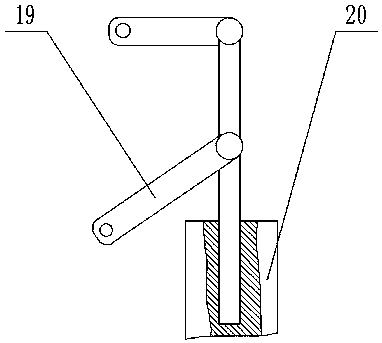

[0016] Such as Figure 1-Figure 3 As shown, an automatic rehabilitation nursing bed driven by a linear motor includes a vertical support bed frame 2, a leg bed board 5, a back bed board 6, a head supporting board 7, and a linear motor mechanism 9. The vertical support bed The bottom of the frame 2 is equipped with universal casters 1, the top of the vertically supporting bed frame 2 is provided with a horizontal bed frame 3, the top of the horizontal bed frame 3 is equipped with the head supporting plate 7, and the inside of the horizontal bed frame 3 The tail end is equipped with the leg bed board 5, the back bed board 6 is arranged between the leg bed board 5 and the head supporting board 7, and the bedside fence 4 is arranged on both sides of the horizontal bed frame 3, so that The top of the horizontal bed frame 3 is provided with a foldable infusion stand 8, the foldable infusion stand 8 is arranged inside the slotted support plate 20 at the head of the bed, the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com