Packaging structure of exposed guide rails of fireproof roller shutter door

A technology for fire shutters and shutter doors, applied in fire doors, windows/doors, building components, etc., can solve the problems of difficulty in ensuring the stability of fire partition walls, small cross-sectional dimensions of guide rails, easy cracking, etc. The effect of rock wool board, improving installation efficiency and eliminating fire hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

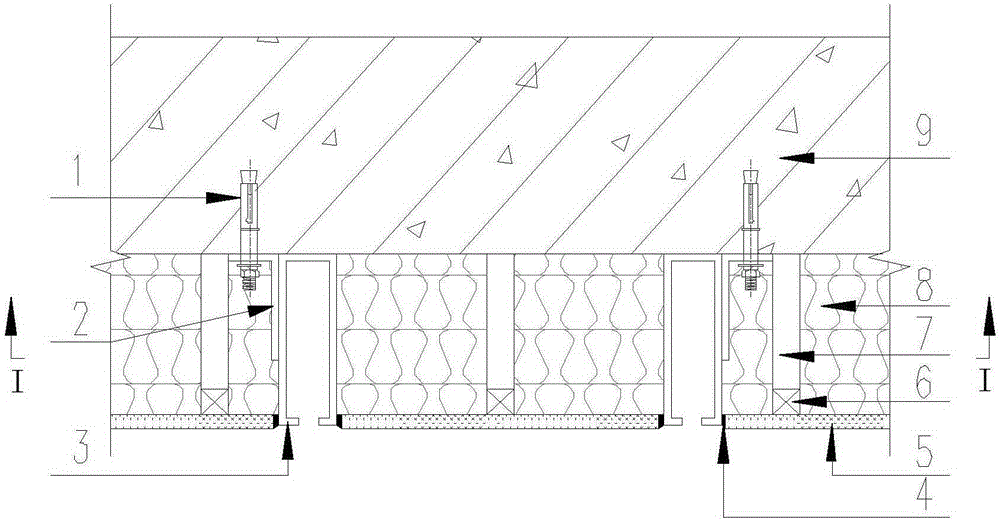

[0015] Such as figure 1 and 2 As shown, the encapsulation structure of the exposed guide rail of the fire shutter door of the present invention includes: angle steel sheet 2 , fireproof rock wool board 5 , vertical pillar 6 , transverse pillar 7 and fireproof rock wool layer 8 .

[0016] The guide rail 3 of the fireproof rolling door is vertically installed on the fireproof partition wall 9, one side wing plate of the angle steel sheet 2 is used to be fixed on the guide rail 3 of the rolling shutter door, and the other side wing plate is used to be fixed on the fireproof partition wall 9 through the anchor bolt 1; One end of the transverse strut 7 is vertically installed on the vertical strut 6 to form an integral support; the left and right sides of the guide rail 3 are provided with an integral support, and the other end of the transverse strut 7 of the integral support is vertically installed on the fireproof partition wall 9, so that the vertical Install vertically to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com