Ground pre-reinforcement treatment method for underground space construction

A technology of underground space and treatment method, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of unable to prevent weathering, unable to seal the surrounding rock, cracked rock peeling, etc., to achieve good seismic resistance, improve self-stability, fully The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

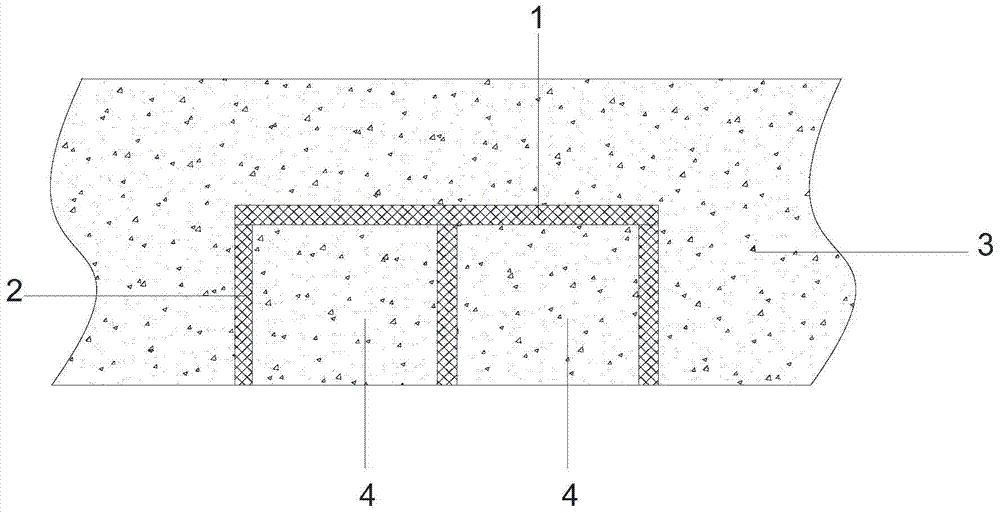

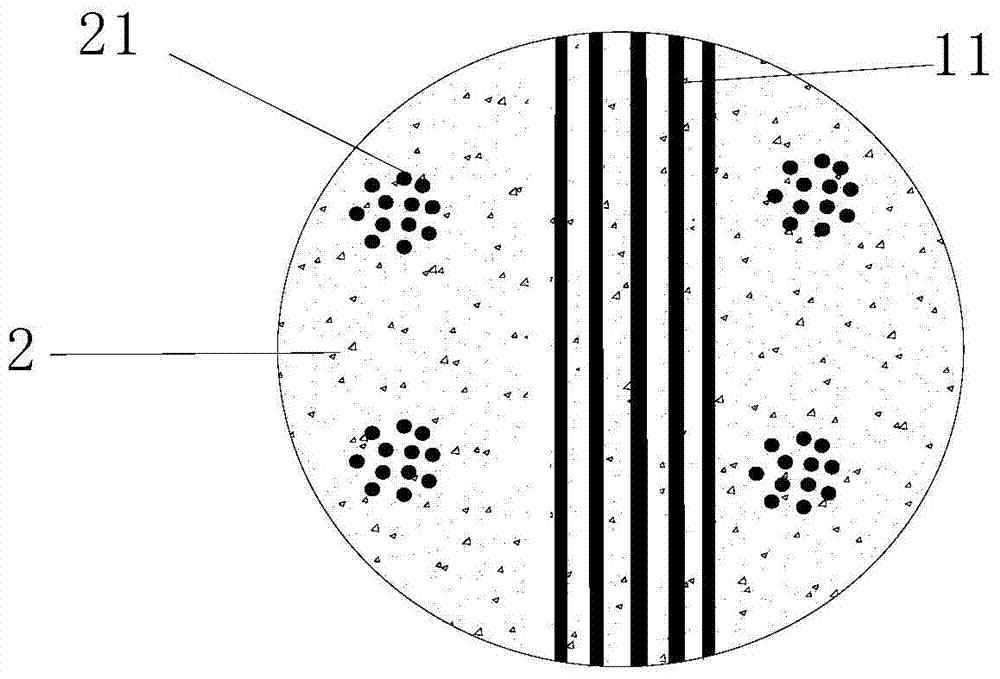

[0019] figure 1 Schematic diagram of the pre-reinforcement treatment structure for the underground space, figure 2 It is a cross-sectional view of the connecting portion of the horizontal perforated pile and the vertical perforated pile; The stratum 3 around the contour line of the proposed underground space 4 is overlapped with the horizontal perforated pile 1 and the vertical perforated pile 2 to form a cross-section simply supported beam support structure on the excavation surface; before the excavation of the underground space, along the proposed The stratum 3 around the contour line of the underground space is reinforced horizontally and vertically to form a support structure that can support the stratum. The vertical perforated pile 2 is carried out above the proposed underground space, and the horizontal perforated pile 1. It is carried out on the stratum adjacent to the side of the excavation surface. First, the stratum is partially excavated as the construction surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com