Method for adapting transient compensation

An adaptation and injection valve technology, applied in fuel injection control, engine control, machine/engine, etc., can solve the problems of high cost, high cost, time-consuming, etc., and achieve the effect of reasonable cost and avoiding additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

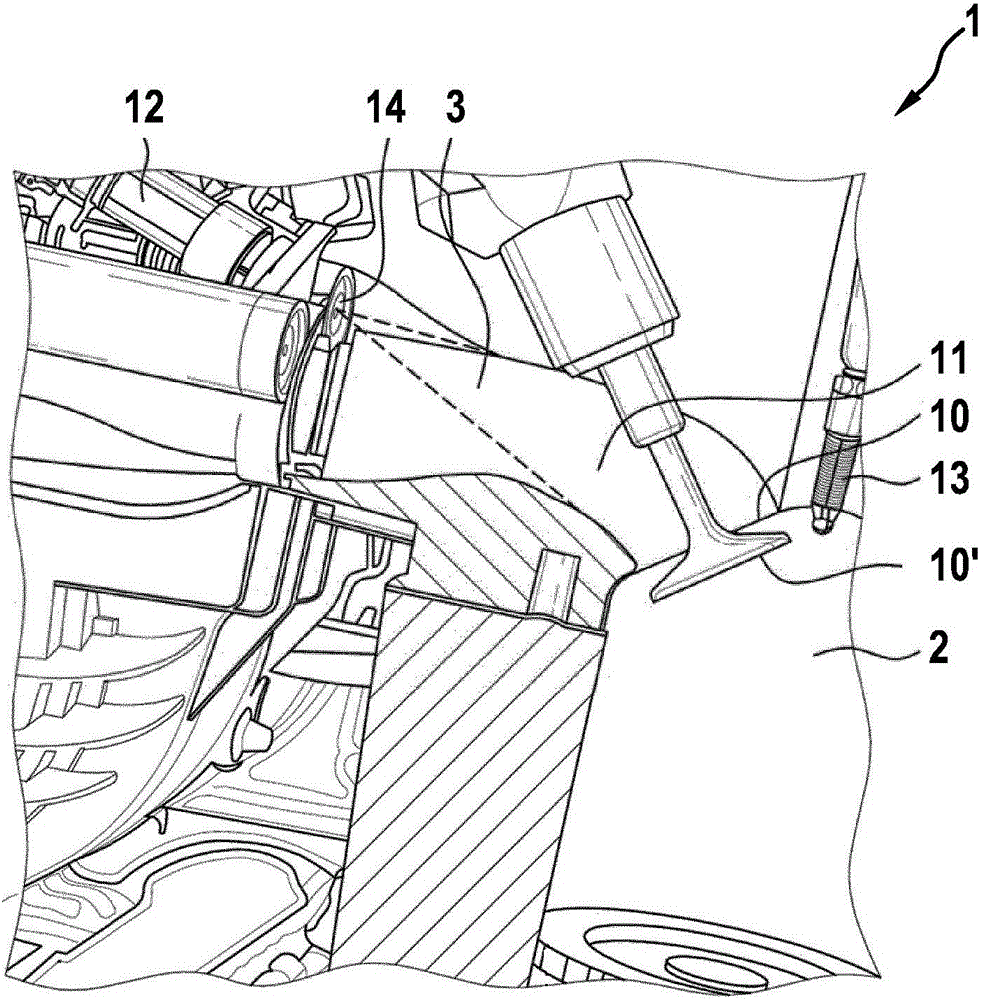

[0023] exist figure 1 shows a diagram of a part of an internal combustion engine 1 comprising a combustion chamber 2, an injection valve 12, an intake valve 10', an ignition device 13, an injection valve port 14, an intake port 10 and a first intake pipe 11, fuel 3 It is injected into the first intake pipe 11 toward the combustion chamber, and the second intake pipe is also provided (in figure 1 not shown). The fuel is atomized in the form of a spray cone when injected, which is figure 1 is shown by dashed lines. It can be seen from this illustration that, in the real embodiment of the internal combustion engine 1 , the fuel 3 is also injected onto the wall of the intake manifold 11 during the injection.

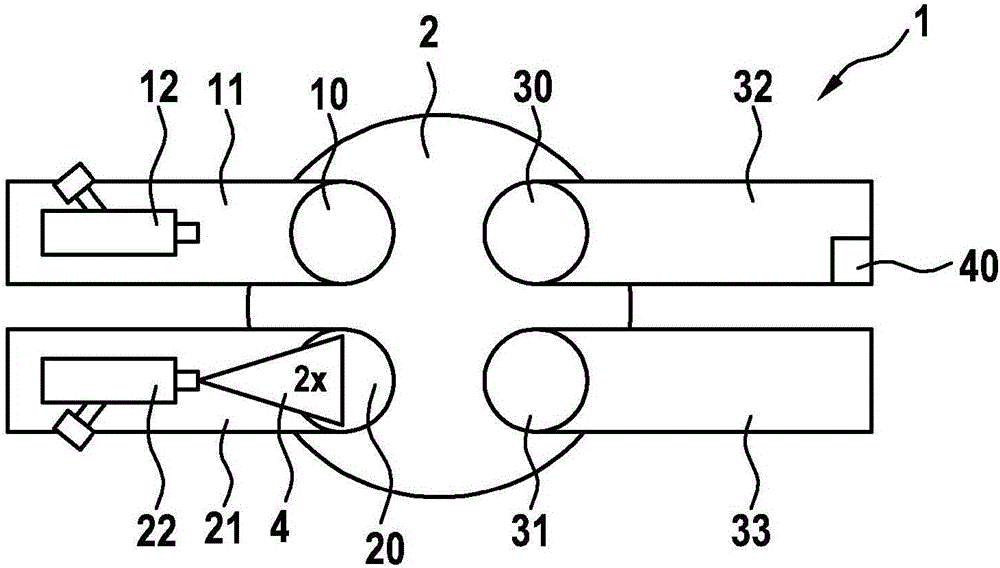

[0024] exist Figure 2a and Figure 2bA schematic illustration of a part of the internal combustion engine 1 which implements the first method step of the method according to an exemplary embodiment of the invention is shown in . The internal combustion engine has a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com