Solid writing material

A writing and solid technology, which is applied to writing utensils, printing, pencil leads, etc., can solve the problems of not considering the use of reversible thermochromic composition and not including solid writing, so as to avoid defects in appearance and improve Moldability and the effect of less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101

[0180] (manufacture of writable core kneading)

[0181]

[0182] The above compound was kneaded with a kneader to obtain a kneaded product of a writable inner core.

[0183] (manufacture of kneaded product of shell)

[0184]

[0185] The above compound was kneaded with a kneader to obtain a kneaded product of the shell.

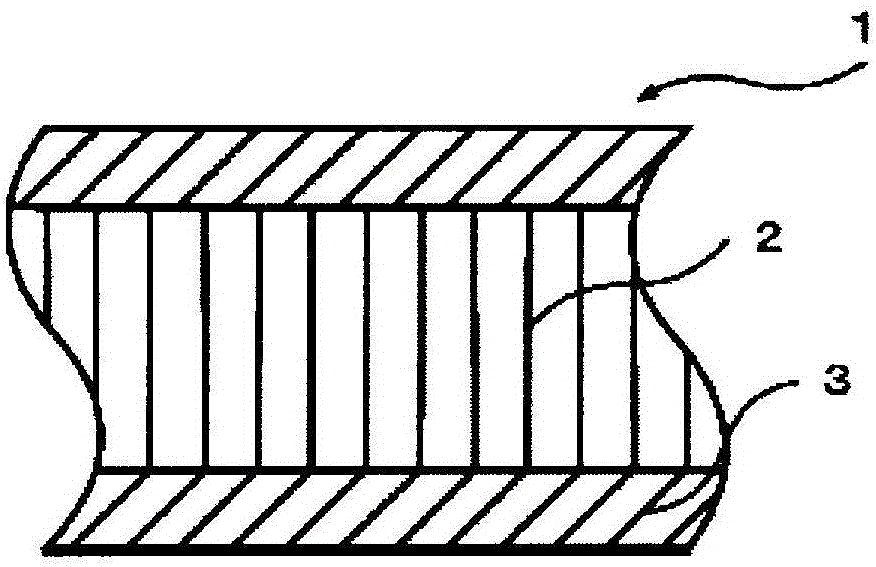

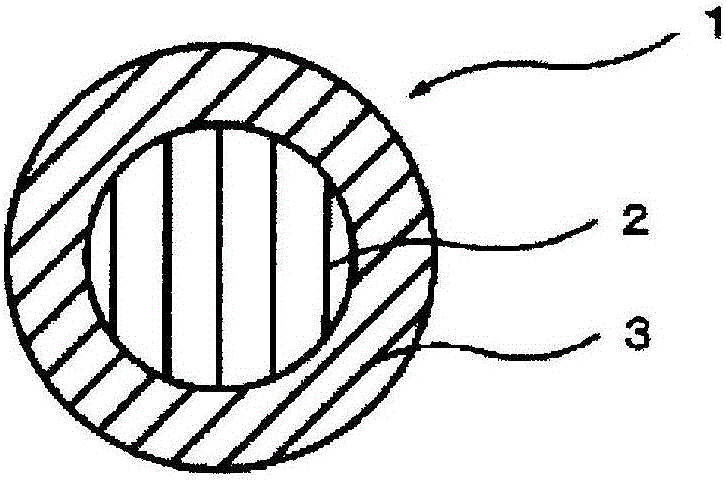

[0186] (production of solid writing)

[0187] On the outer peripheral surface of the kneaded material of the obtained writable inner core, wrap the kneaded material of the outer shell, utilize a press to carry out compression molding, and mold it into an outer diameter of φ3mm and a length of 60mm (the writable inner core is φ2mm, and the outer diameter of the outer shell is φ2mm). The covering thickness was 0.5 mm), and a solid writing body provided with a shell covering the outer peripheral surface of the writable inner core was obtained.

Embodiment 102~118

[0189] With the combination shown in (Table 1), a solid writing body was obtained by the same method as in Example 101.

Embodiment 201~219、 comparative example 201~203

[0232] The raw materials were blended in the ratios shown in Tables 2-1 and 2-2, and the same method as in Example 101 was used to obtain the solid writing materials of Examples 201-219 and Comparative Examples 201-203.

[0233] Using the solid writing materials obtained in Examples 201 to 219 and Comparative Examples 201 to 203, the affinity, impact resistance, formability and bending strength of the solid writing materials were evaluated by the following methods. The obtained results are shown in Tables 2-1 and 2-2.

[0234] (1) Affinity: visually observe the solid writing body, further apply torsional stress to the solid writing body, and observe the degree of damage to evaluate the affinity between the shell and the inner core.

[0235] A: Cracks and latent cracks were not confirmed, and the affinity was very good.

[0236] B: Potential cracks were slightly confirmed, but affinity was good.

[0237] C: Potential cracks were slightly confirmed, but the affinity was at a pra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com