Pressing plate gluing brush

A technology of pressing board glue and pressing board, which is applied in snow surface cleaning, construction, cleaning methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

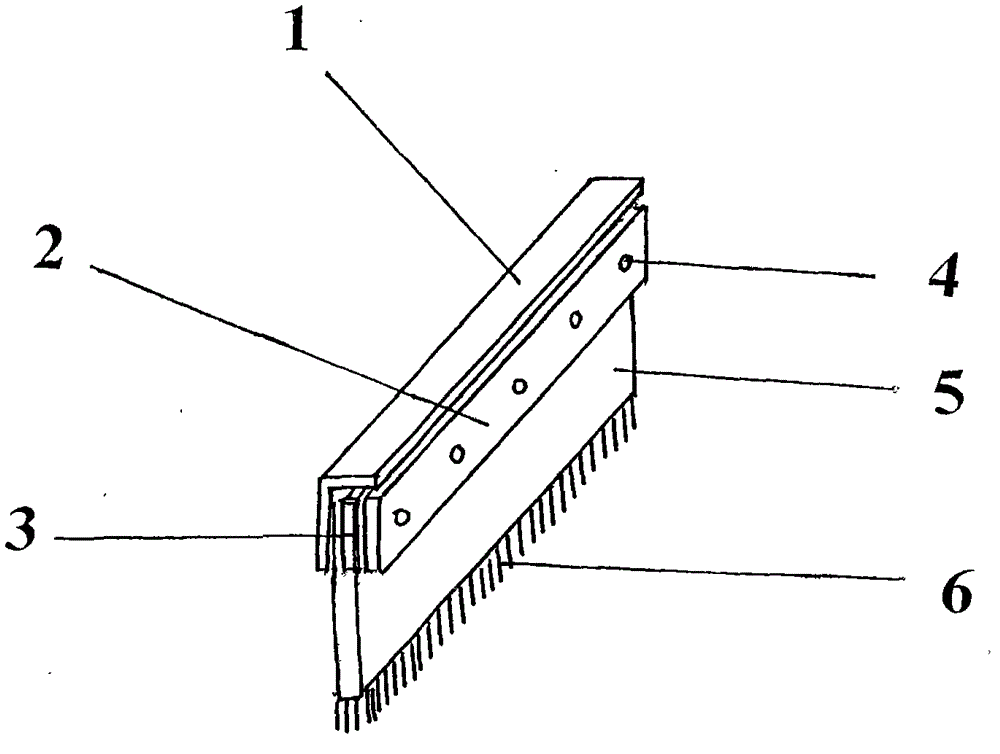

[0007] A pressure plate adhesive brush is characterized in that: the pressure plate adhesive brush includes an L-shaped pressure plate 1, a rectangular pressure plate 2, a rectangular splint 3, a canvas circumference 5, and countless U-shaped steel wires 6. Among them, countless U-shaped steel wires 6 are set on the rectangular splint 3, an L-shaped pressing plate 1 on one side, a rectangular pressing plate 2 on the other side, L-shaped pressing plate 1, and a rectangular pressing plate 2. The rectangular splint 3 covered with countless U-shaped steel wires 6 Sandwiched in the middle and fixed together by a plurality of bolts and nuts 4; the canvas skirt 5 and countless U-shaped steel wires 6 are bonded together by glue (not shown in the figure).

[0008] To sum up, the efficacy of the present invention has been significantly improved, has practicability and operability, and meets the requirements of the invention patent, so the application for the invention patent is filed acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com